Low-impurity high-yielding gellan gum-producing bacteria and its application

A technology for gellan gum and bacteria production, which is applied in the direction of bacteria, microorganisms, microorganisms, etc., to achieve the effect of reducing purification cost, increasing yield and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1. Screening of gellan gum-producing bacteria without nodocaxanthin (EMS mutagenesis and high-efficiency screening):

[0028] 1), the first round of mutagenesis treatment:

[0029] The slant of the sphingomonas elatiens ATCC 31461YM medium preservation was transferred to the LB liquid medium, cultivated at 30°C for 16h, and then added EMS (ethyl methanesulfonate) according to the volume ratio of 1% of the LB liquid medium to avoid Leave at room temperature for 1 hour, then transfer to fresh YM liquid medium, and incubate at 30°C for 6 hours.

[0030] The composition of YM liquid medium: peptone 5g / L, malt extract powder 3g / L, glucose 10g / L, yeast powder 3g / L, solvent is water, pH7.0.

[0031] The composition of YM solid medium: peptone 5g / L, malt extract powder 3g / L, glucose 10g / L, yeast powder 3g / L, 15g / L agar, solvent is water, pH7.0.

[0032] 2) The samples obtained from the first round of mutagenesis treatment were spread on the YM plate (YM solid medium) ...

Embodiment 2

[0034] Example 2, Screening of gellan gum-producing bacteria without nodocaxanthin and PHB:

[0035] 1), the second round of mutagenesis treatment:

[0036] The strain obtained in Example 1 with the highest gellan gum polysaccharide yield and no nodocaxanthin production was used as the starting strain for the second round of mutagenesis, transferred to YM liquid medium, cultured at 30°C for 16h, and then followed the YM liquid medium Add EMS at a volume ratio of 1%, place at room temperature for 1 h in the dark, then transfer to fresh YM medium, and incubate at 30°C for 6 h.

[0037] 2) The samples obtained from the second round of mutagenesis treatment were serially diluted and spread on YM solid medium added with 5 μg / mL Nile blue Nile blue fluorescent agent, and cultured at 30° C. for 72 hours. Among them, Nile blue can be combined with PHB to make the PHB-containing strains produce fluorescence under ultraviolet light, while the non-fluorescence or extremely weak fluoresc...

Embodiment 3

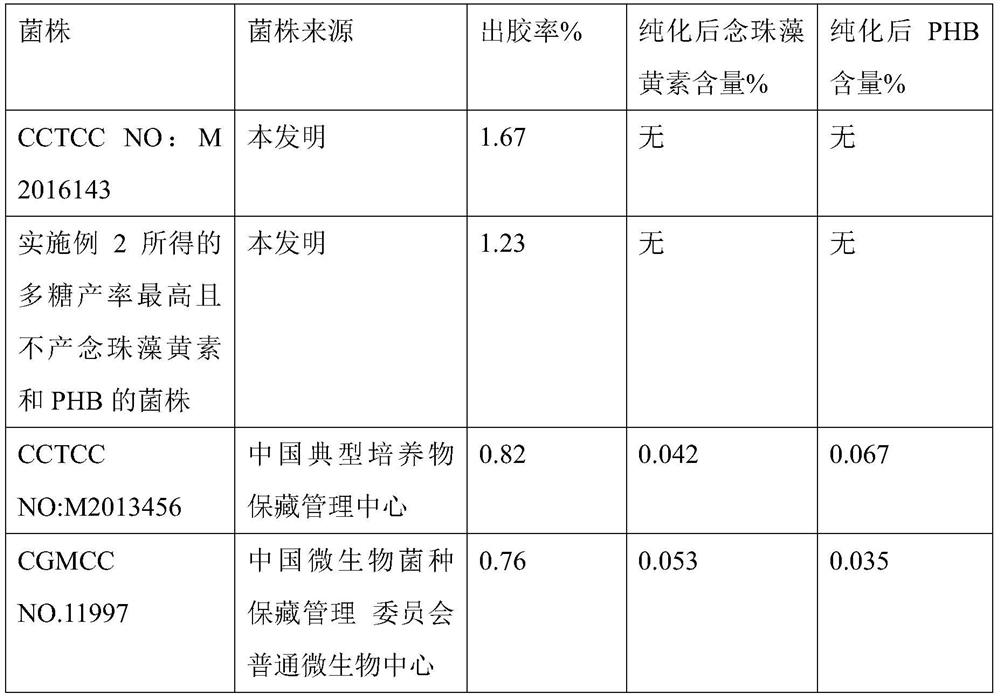

[0039] Example 3, Screening of producing bacteria that do not contain nodocaxanthin and PHB and high-yield gellan gum:

[0040] 1), the third round of mutagenesis treatment:

[0041]The strain obtained in Example 2 with the highest polysaccharide yield and no nodocaxanthin and PHB was the starting strain for the third round of mutagenesis, transferred to YM liquid medium, cultivated at 30°C for 16h, and then followed the method of 1% YM liquid medium. Add EMS to the volume ratio, place at room temperature in the dark for 1 hour, transfer to fresh YM medium, and incubate at 30°C for 6 hours;

[0042] 2) The samples obtained from the third round of mutagenesis treatment were serially diluted and spread on a YM high-yield screening plate supplemented with 100 μg / mL ampicillin, and cultured at 30° C. for 5 days.

[0043] Recipe for YM high yield screening plate supplemented with 100 μg / mL ampicillin:

[0044] Peptone 5g / L, malt extract powder 3g / L, glucose 10g / L, yeast powder 3g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com