Method and processing system for constant laser beam terminal energy

A processing system and laser beam technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of uneven laser beam terminal energy, non-compliance with market demand, high incidence of defects, etc., and achieve simplified structure and simplification The effect of reducing the structure and failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

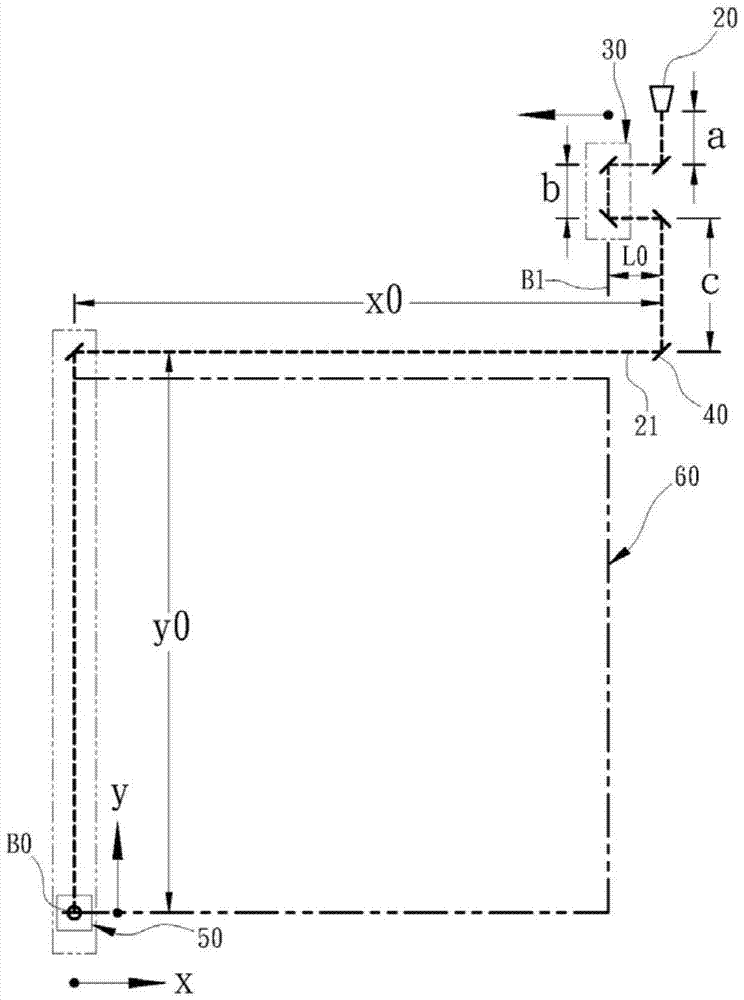

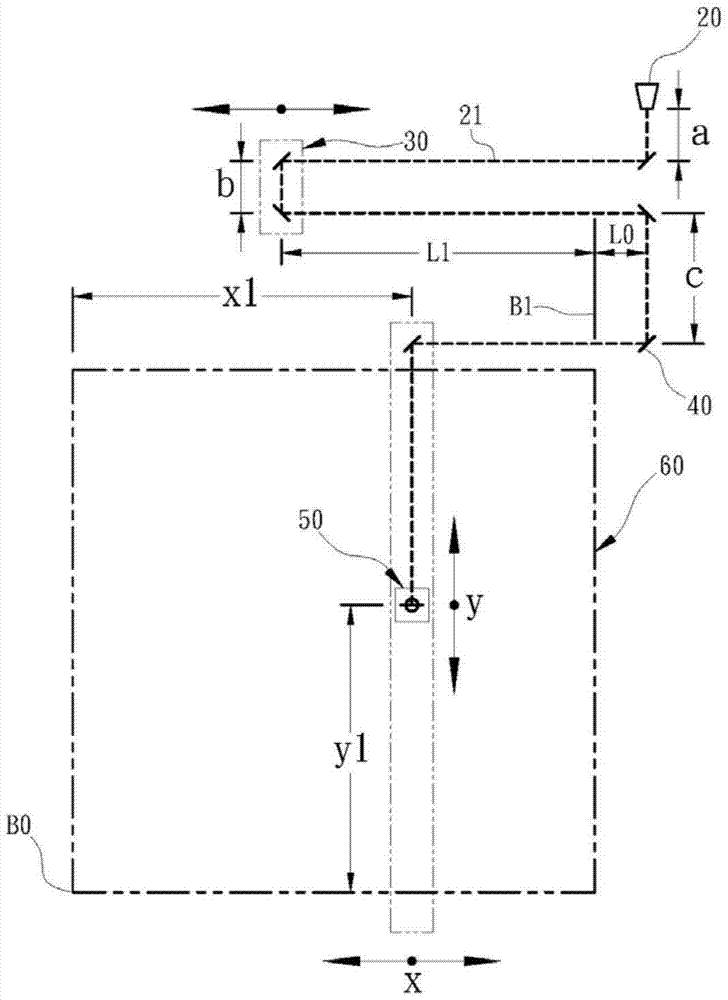

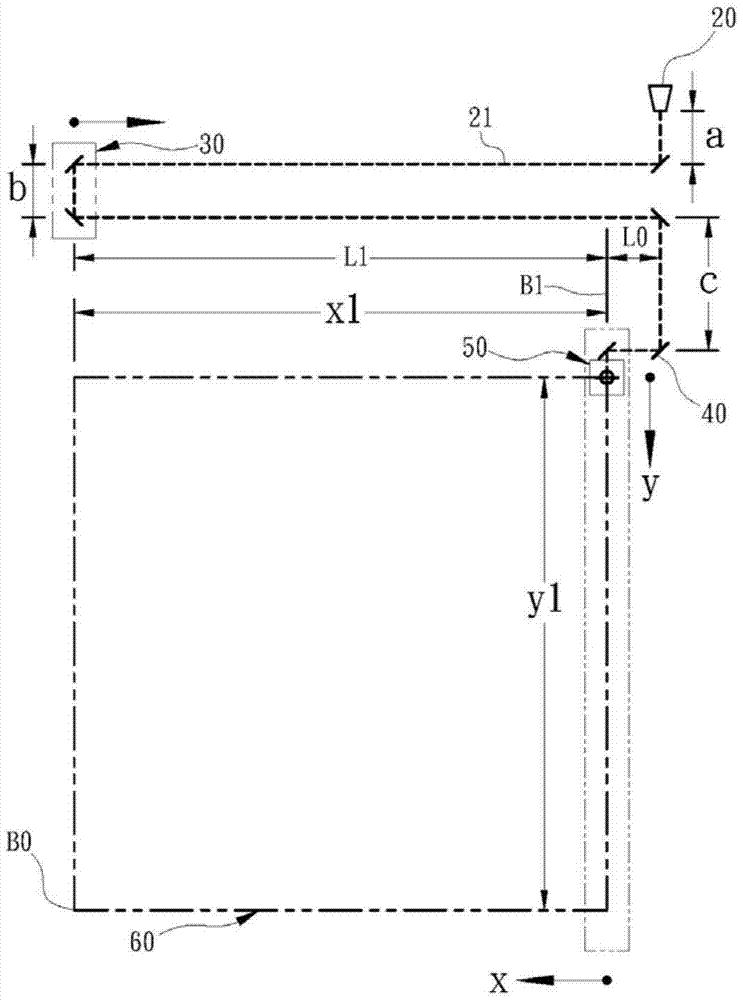

[0037] Regarding the method of constant laser beam terminal energy and its processing system of the present invention, its preferred embodiment and detailed technical content, it will be described as follows with reference to the drawings. First, please also see figure 1 "~" Figure 4 ” is a schematic plan view from above of the first preferred embodiment of the present invention and a three-dimensional schematic view of its continuous actions and implementation states. As shown in the figure, it can be clearly seen that the method of the present invention includes: providing a laser light source 20 capable of irradiating a light beam 21; providing a terminal action unit capable of being displaced and receiving the light beam 21 to guide it to a terminal irradiation position 50; provide at least one spacing adjustment unit 30 located in the path of the beam 21 and linearly displaced; provide at least four reflectors 40 between the laser light source 20 and the terminal action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com