Annular reciprocating closed electrospinning device

A reciprocating, electrospinning technology, applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of waste of spinning solution, reduced spinning efficiency and quality, discontinuous electric field, etc. Yield, overcoming poor uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

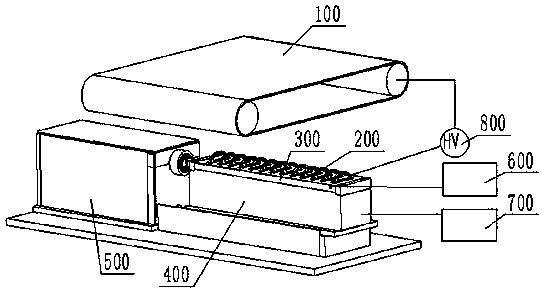

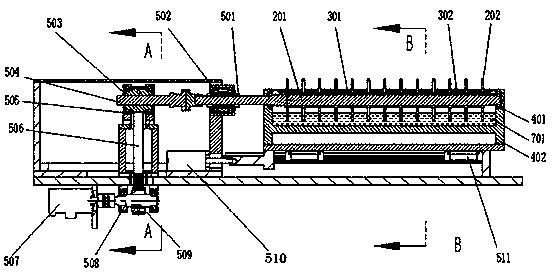

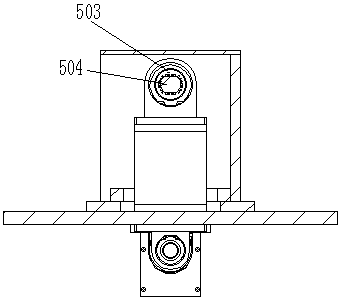

[0108] Such as figure 1 and figure 2 As shown, the mobile rotating mechanism 500 is composed of a linear bearing 501, a rolling bearing 502, a driven synchronous pulley 503, a driven shaft 504, a rolling bearing 505, a synchronous belt 506, a servo motor 507, a driving shaft 508, a driving synchronous pulley 509, a cylinder 510 and 511 linear slides. The driving synchronous pulley 509 has the same tooth profile as the driven synchronous pulley 503 , and the number of teeth is equal, and they are connected together by a synchronous belt 506 . The central hole of the driven synchronous pulley 503 has double-plane steps, and grooves are provided on the two planes and the arc surface to reduce the friction generated when the central shaft reciprocates, as shown in the side sectional view image 3shown. Driven shaft 504 one end has two platform surfaces, cooperates with driven synchronous belt pulley 503 central holes, can make driven synchronous belt pulley 503 drive driven sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com