Manufacturing method of thin-wall steel pipe confined bamboo member

A technology of thin-walled steel pipes and manufacturing methods, which is applied in building construction, construction, etc., can solve the problems of concrete weight and high energy consumption, and achieve the effects of low cost, high efficiency, and easy standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

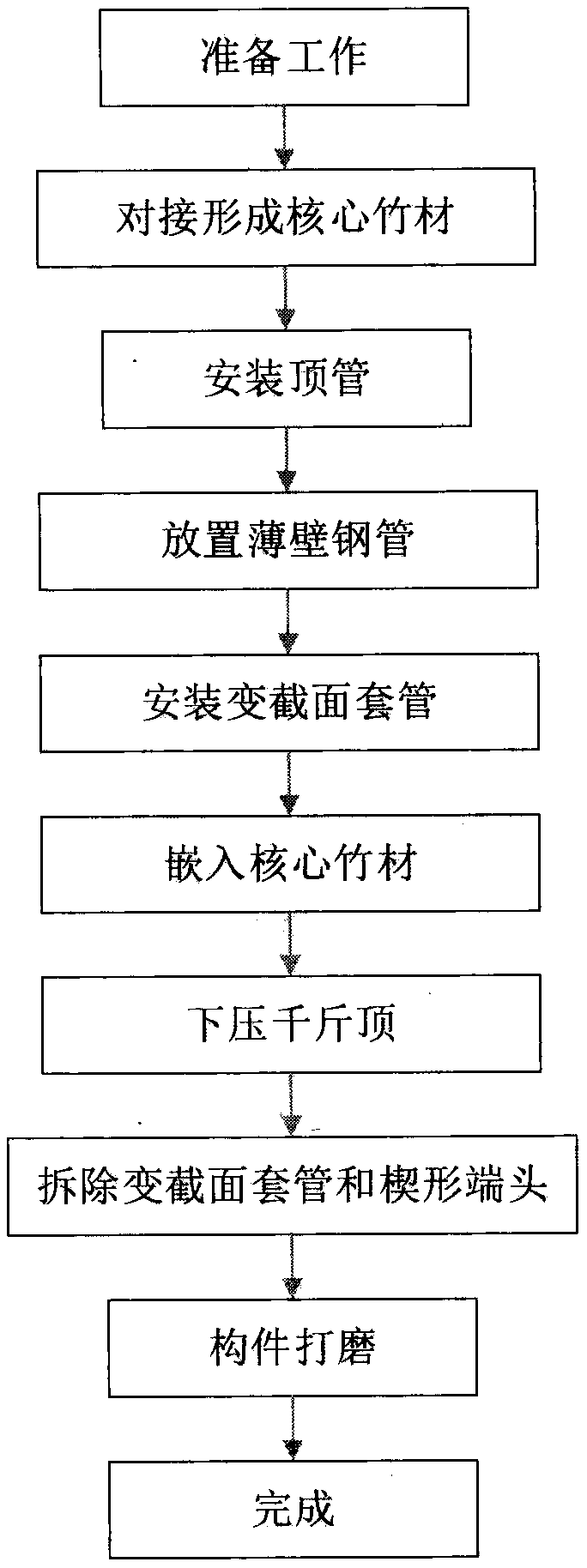

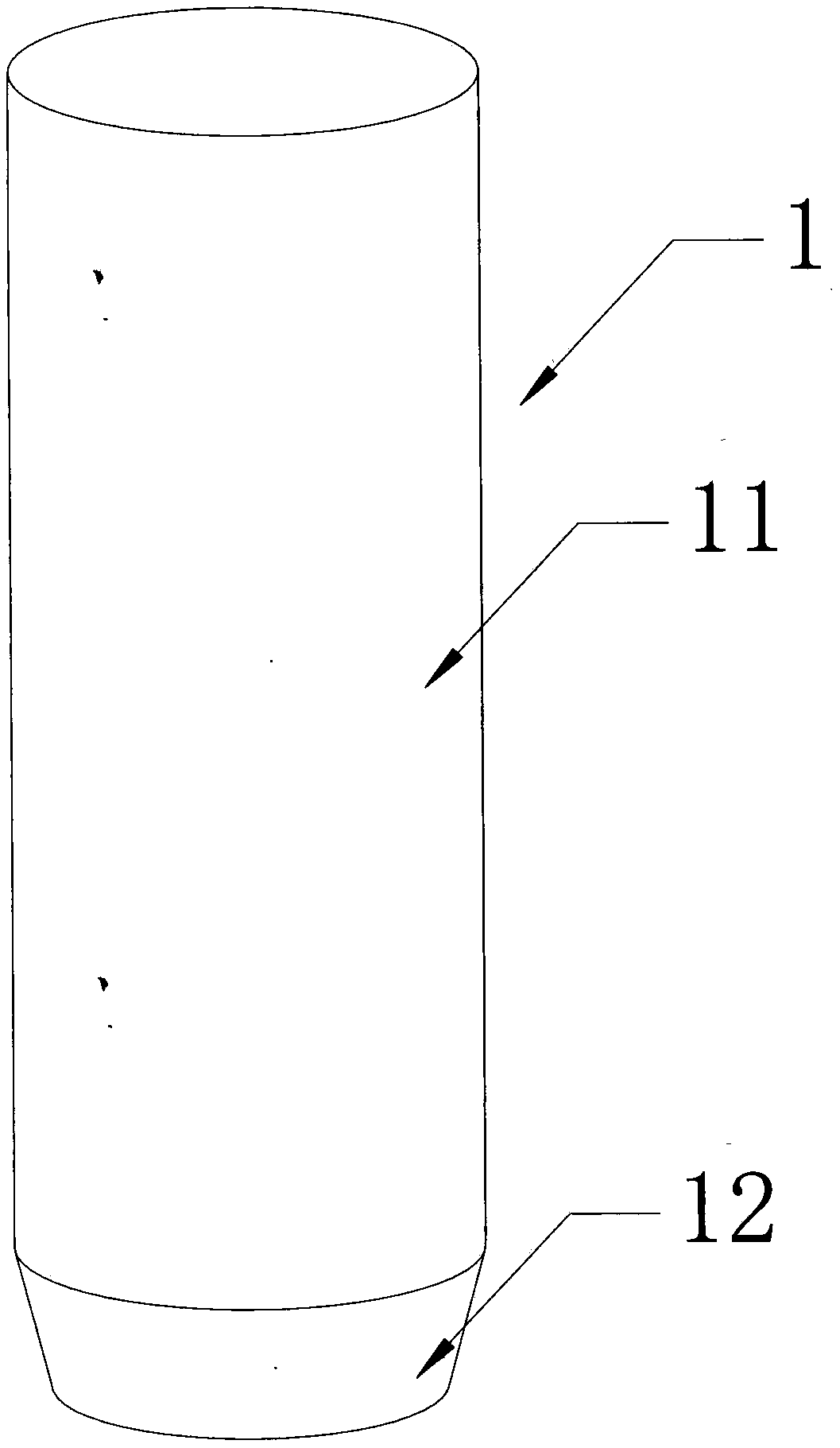

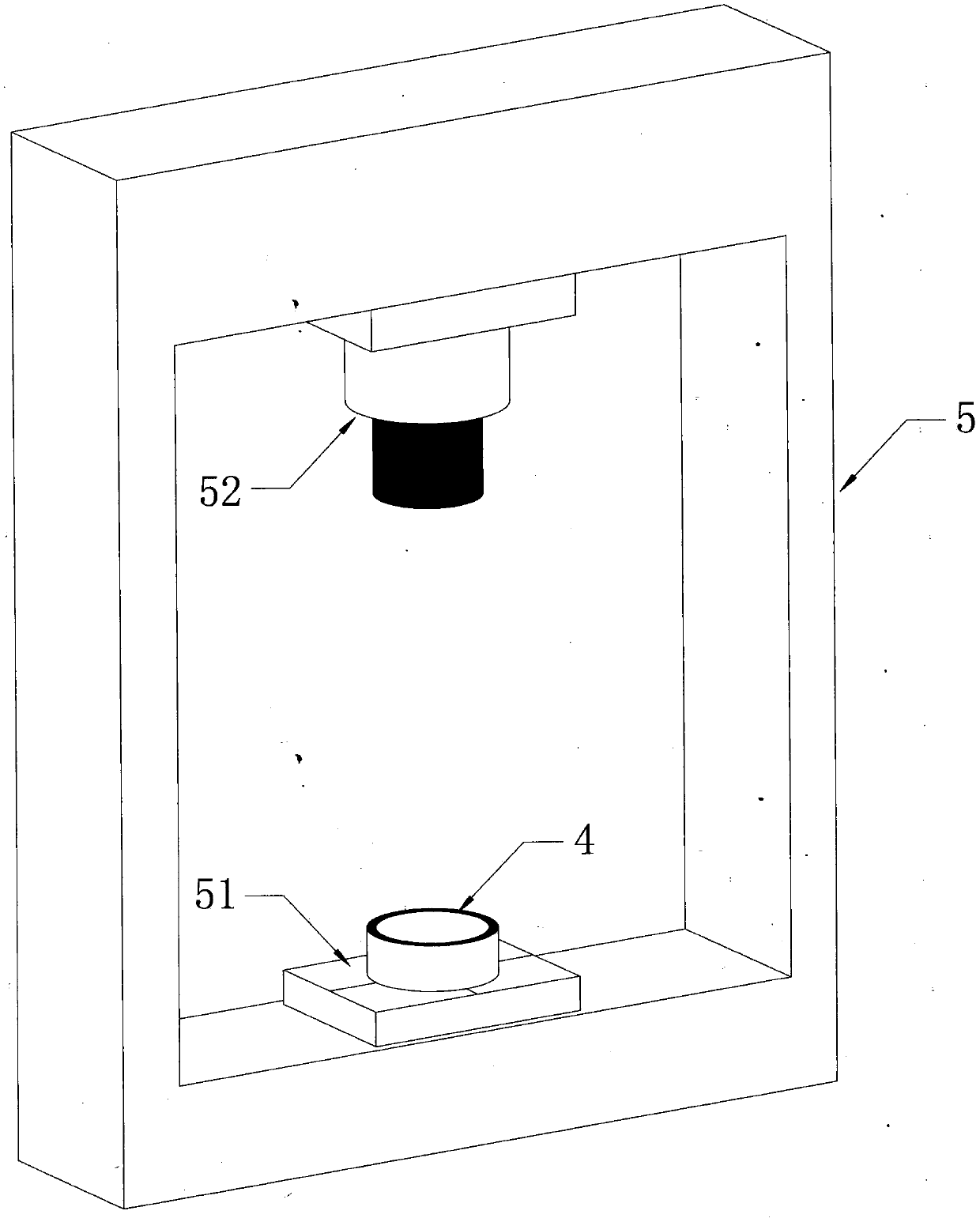

[0048] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings. The present invention provides a method for manufacturing thin-walled steel pipe constrained bamboo components. The core bamboo material is formed by butting a constant-section bamboo section 11 and a wedge-shaped end 12 to form a core bamboo material 1, installing a top pipe 4, placing a thin-walled steel pipe 2, and installing a variable-section sleeve 3 , Embed the core bamboo material 1, press down the jack 52, remove the variable section casing 3 and the jacking pipe 4, and polish the components to form a thin-walled steel pipe constrained bamboo member. The static pressure device 5 is composed of a base 51 and a jack 52 The core bamboo 1 is composed of a constant cross-section bamboo section 11 and a wedge-shaped end 12. The wedge-shaped en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com