Design method of composite concrete overlay structure for repairing road intersection

A technology for structural design and concrete, which is applied to cohesive pavement paved on site, roads, roads, etc., to achieve good bonding, reduce construction costs, and reduce disease effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

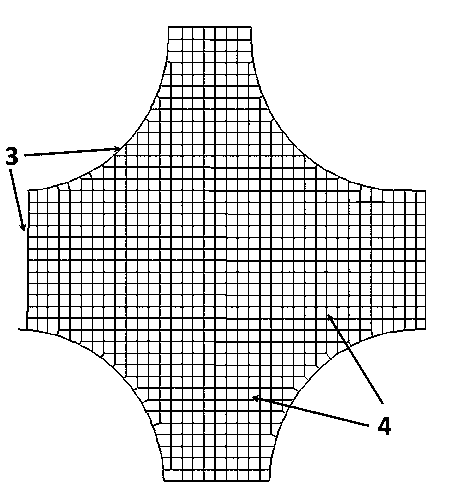

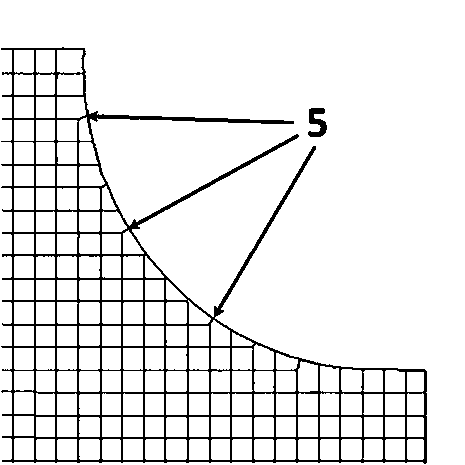

[0038] Such as Figure 1-5 As shown, a method for designing a combined concrete overlay structure at the intersection of repaired roads is provided, including the following steps:

[0039] Step 1. Evaluate the bearing capacity of the existing asphalt pavement by using the dynamic cone penetrometer. The dynamic cone penetrometer detects the penetration rate to obtain the California bearing ratio CBR and elastic modulus E:

[0040] CBR = 292 / PR 1.12

[0041] E(MPa) = 17.58×CBR 0.64

[0042] In the formula, CBR is the California bearing ratio, (%); PR is the penetration rate of the dynamic cone penetrometer test, (mm / hammer time); if the existing pavement is under weak support, go to step 2, otherwise Go to step three.

[0043] Step 2: Reinforce the existing pavement to achieve sufficient supporting capacity until the existing asphalt pavement includes at least 50 mm of asphalt surface layer and at least 150 mm thick base layer with a strength greater than 345 MPa.

[0044]...

Embodiment 2

[0050] Embodiment 2: The difference between this embodiment and Embodiment 1 lies in that the method used to evaluate the bearing capacity of the existing asphalt pavement in step 1 is a drop weight deflection tester.

Embodiment 3

[0051] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, the method used to evaluate the bearing capacity of the existing asphalt pavement is the combined evaluation of the drop weight deflectometer and the dynamic cone penetrometer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com