Construction method of self-stabilized internal and external sliding and moving type elevator shaft safety protection device

A technology of a safety protection device and a construction method, which is applied in the processing of building materials, construction, and building construction, etc., can solve the problems of low reuse rate, large amount of on-site work, slow construction progress, etc., and achieves good energy saving and environmental protection. The construction quality is guaranteed and the installation is firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

[0038] This embodiment takes the construction of a high-rise building as an example. The building floor height is 3.6m, the size of the elevator shaft is 2.2m×2.1m, and the size of the elevator door opening is 1.1m×2.1m. Type inside and outside sliding elevator shaft safety protection device.

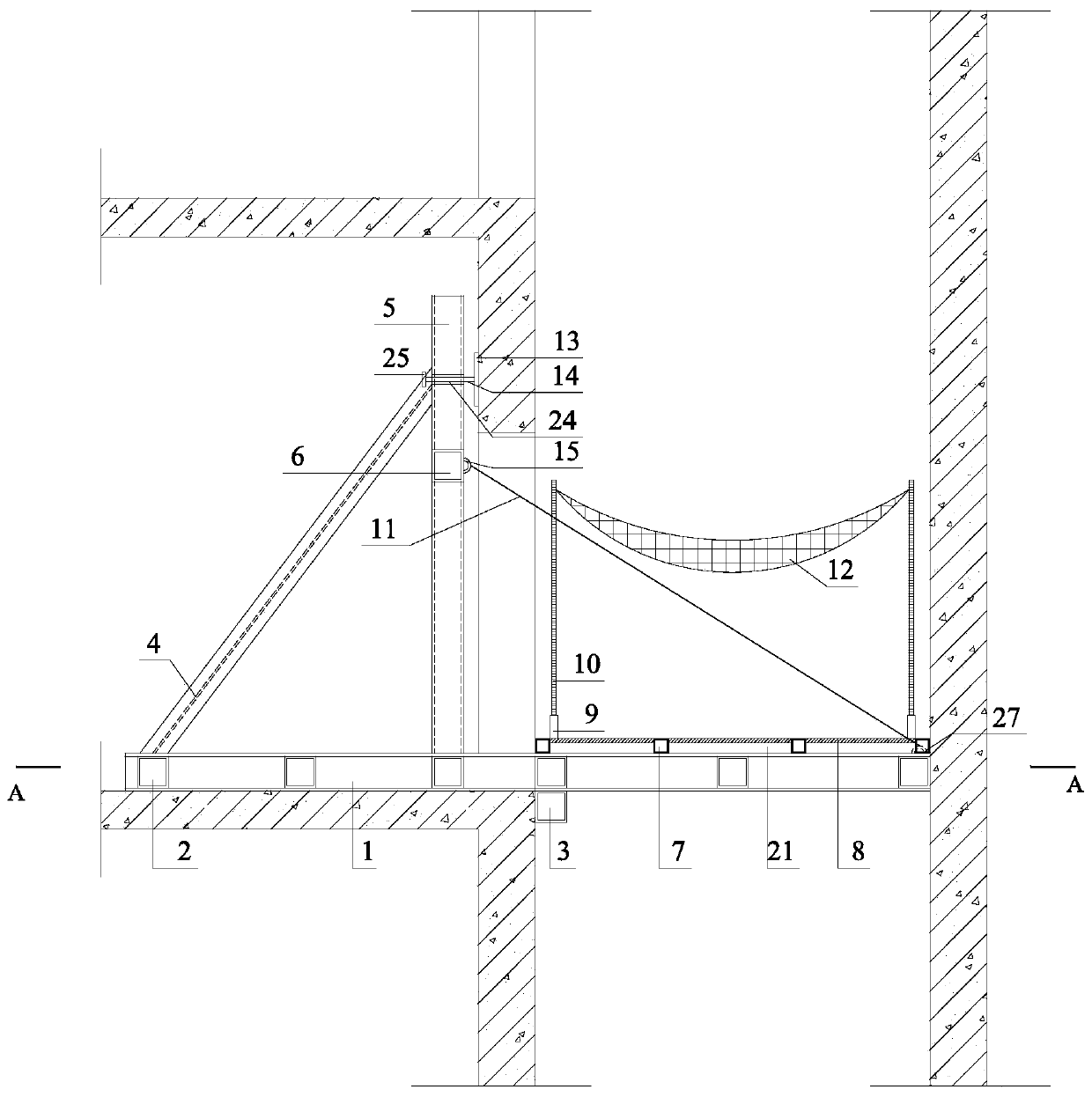

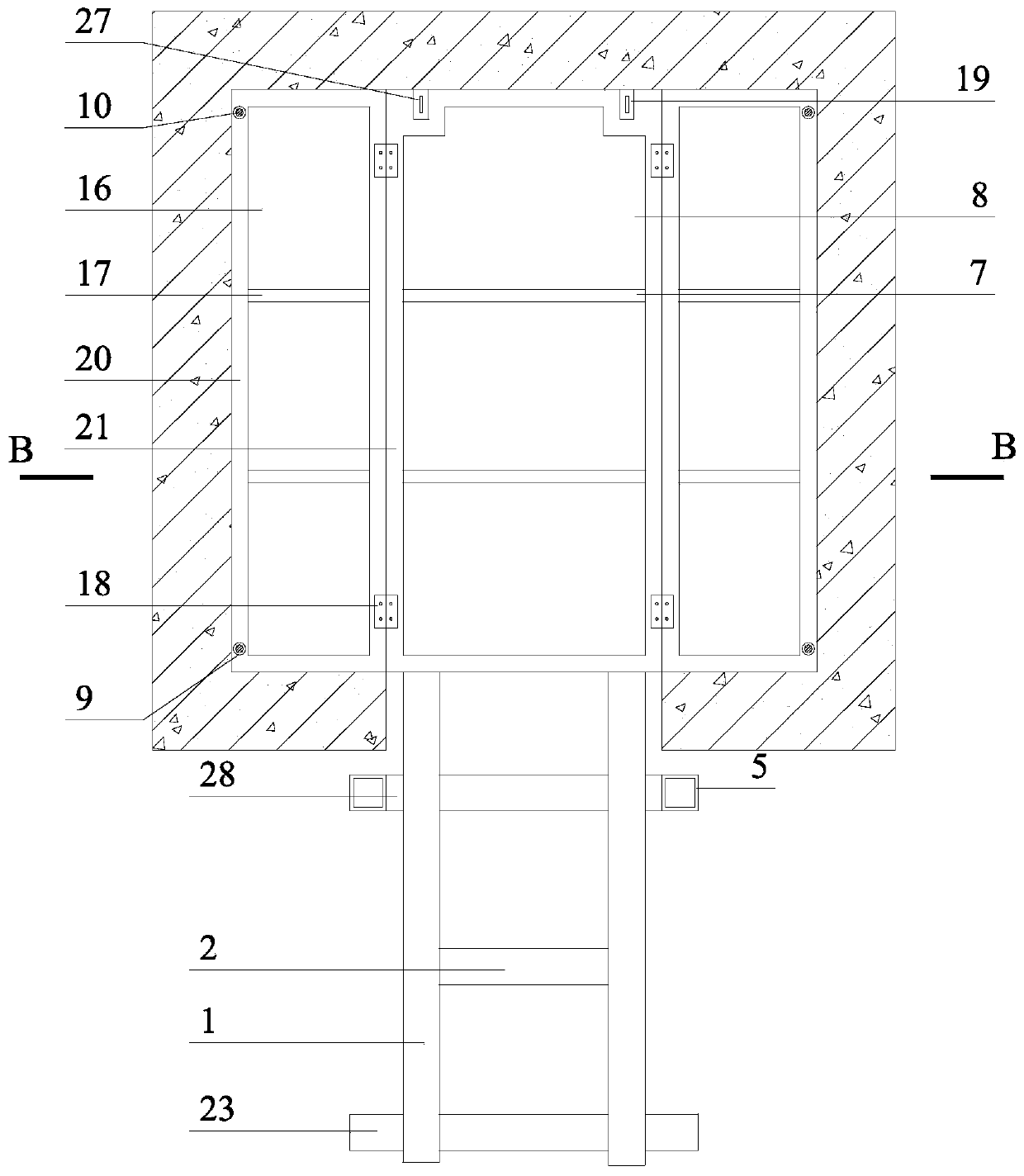

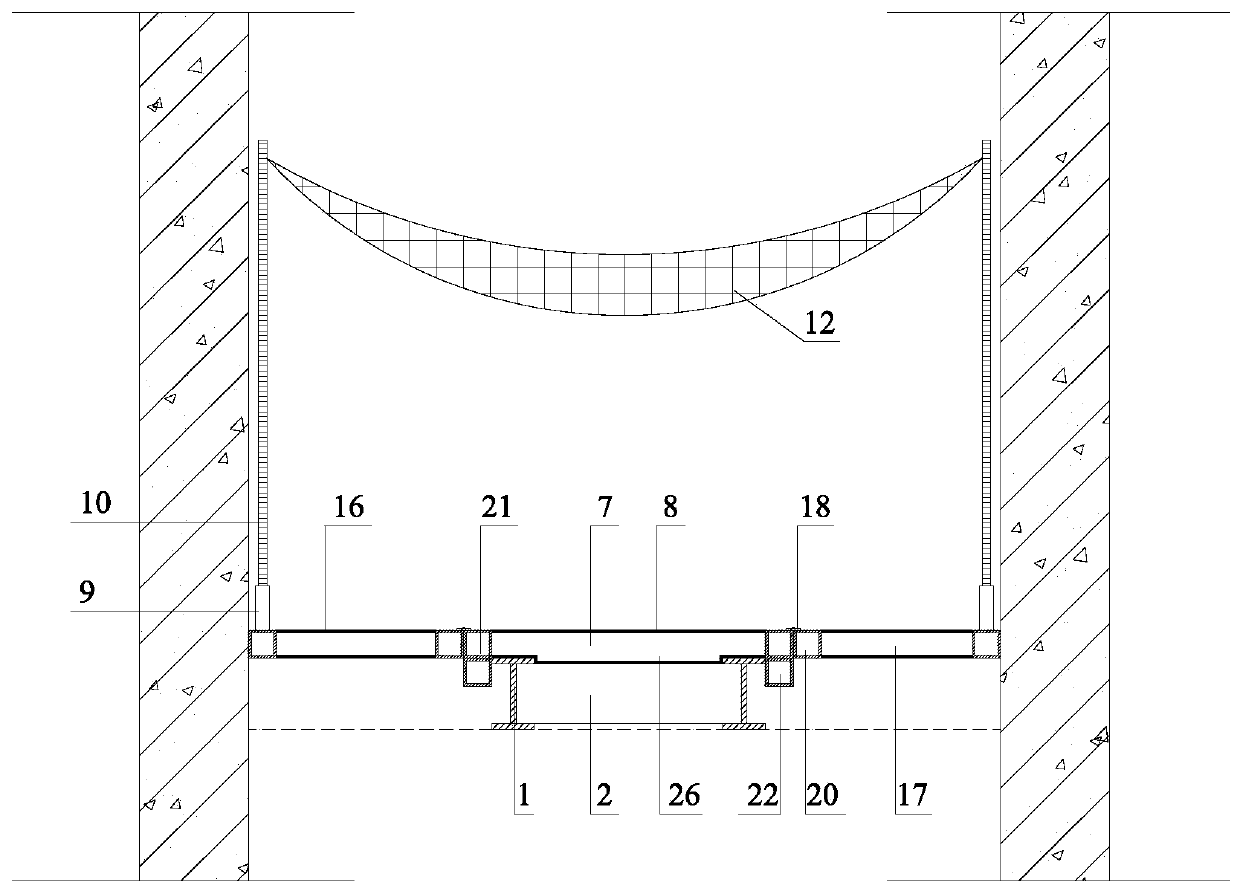

[0039] Such as figure 1 As shown, the present invention relates to a self-stabilizing inner and outer sliding elevator shaft safety protection device, including a suspension frame, a sliding platform and a protection mechanism.

[0040] combined with figure 1 and 2 As shown, the cantilever frame includes a main beam 1, a secondary beam 2, a limit beam 3, a vertical bar 5 and a beam 6. 1 is 4.2m long, vertical bar 5, cross beam 6, secondary beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com