A method for recreating underground water storage space by solid filling mining in coal mines

A technology of solid filling and water storage space, which is applied in the direction of filling, underground mining, surface mining, etc. It can solve the problems of low rainfall in mining areas, loss of water resources, and inability to meet the water demand of coal mine mining, so as to reduce the degree of damage to the ecological environment , to achieve storage and reuse, and to achieve the effect of safe water mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

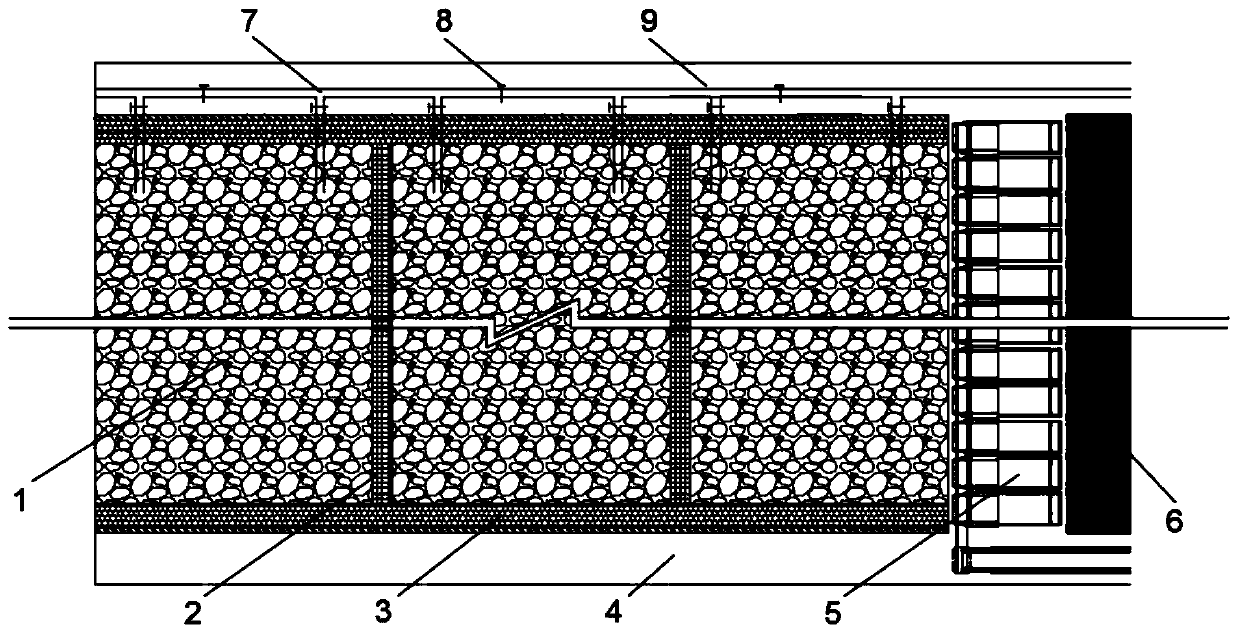

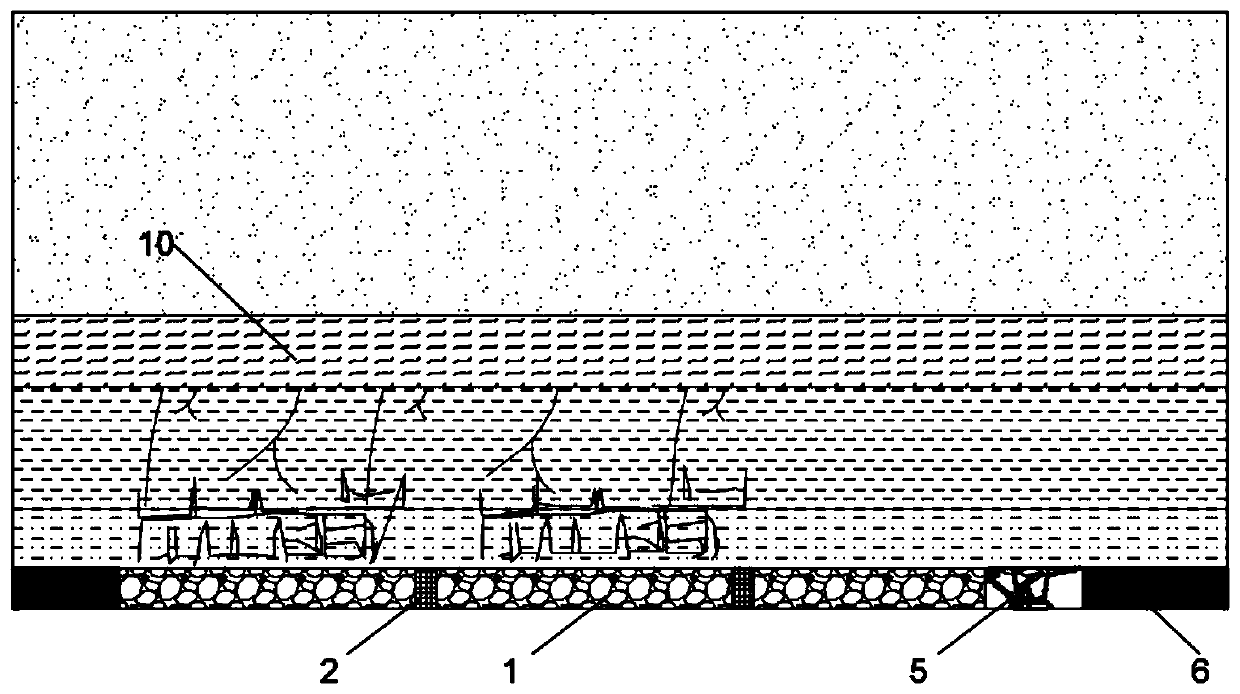

[0021] Below in conjunction with accompanying drawing, the present invention is further described:

[0022] A mine is located in an ecologically fragile mining area in the west, and the water resources in the mining area are very short. The depth of the main mining coal seam of the coal mine is 300m, and the mining height of the coal seam is 3.0m. with gangue material. Above the working face is an aquifer 10 rich in water resources.

[0023] A method for recreating an underground water storage space through coal mine solid filling mining, comprising the following specific steps:

[0024] a. Using comprehensive mechanized solid filling coal mining as a technical means, according to the actual mining geological conditions on site, carry out the selection of working face equipment, system layout and filling coal mining operations;

[0025] b. During the mining process of the working face, gangue and aeolian sand are used as the main materials to carry out the goaf filling opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com