Method for precise grouting reconstruction of roof thin-layer limestone aquifer

A water layer and thin layer technology, which is applied in the field of precise grouting transformation of the roof thin layer limestone aquifer, can solve the problems such as the drying of the roof thin layer limestone aquifer and the inability to precisely control the grouting transformation technology, so as to achieve good economical efficiency. Benefits and social benefits, obvious economic benefits, and the effect of saving and preventing water costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

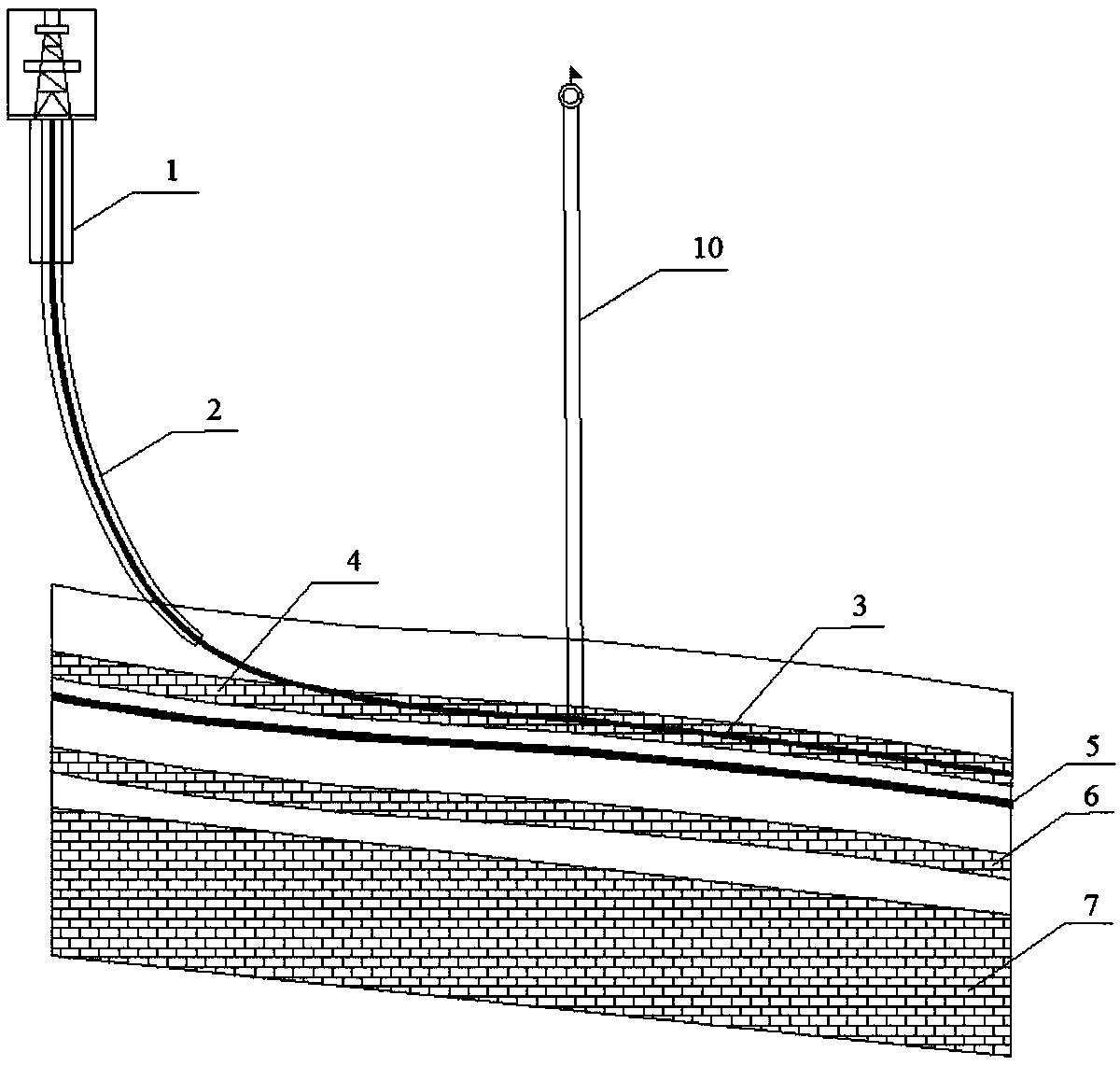

[0034] The invention discloses a method for precise grouting reconstruction of a thin-layered limestone aquifer on the roof, which includes ground directional drilling construction to the thin-layered limestone aquifer on the roof of the mine [4], and close monitoring of the aquifer during the ground directional drilling and grouting [4] ], the grouting parameters such as grouting pressure and grouting materials are adjusted according to the change rate of the hydraulic water level of the aquifer [4], so as to achieve precise control of the grouting radius and grouting effect.

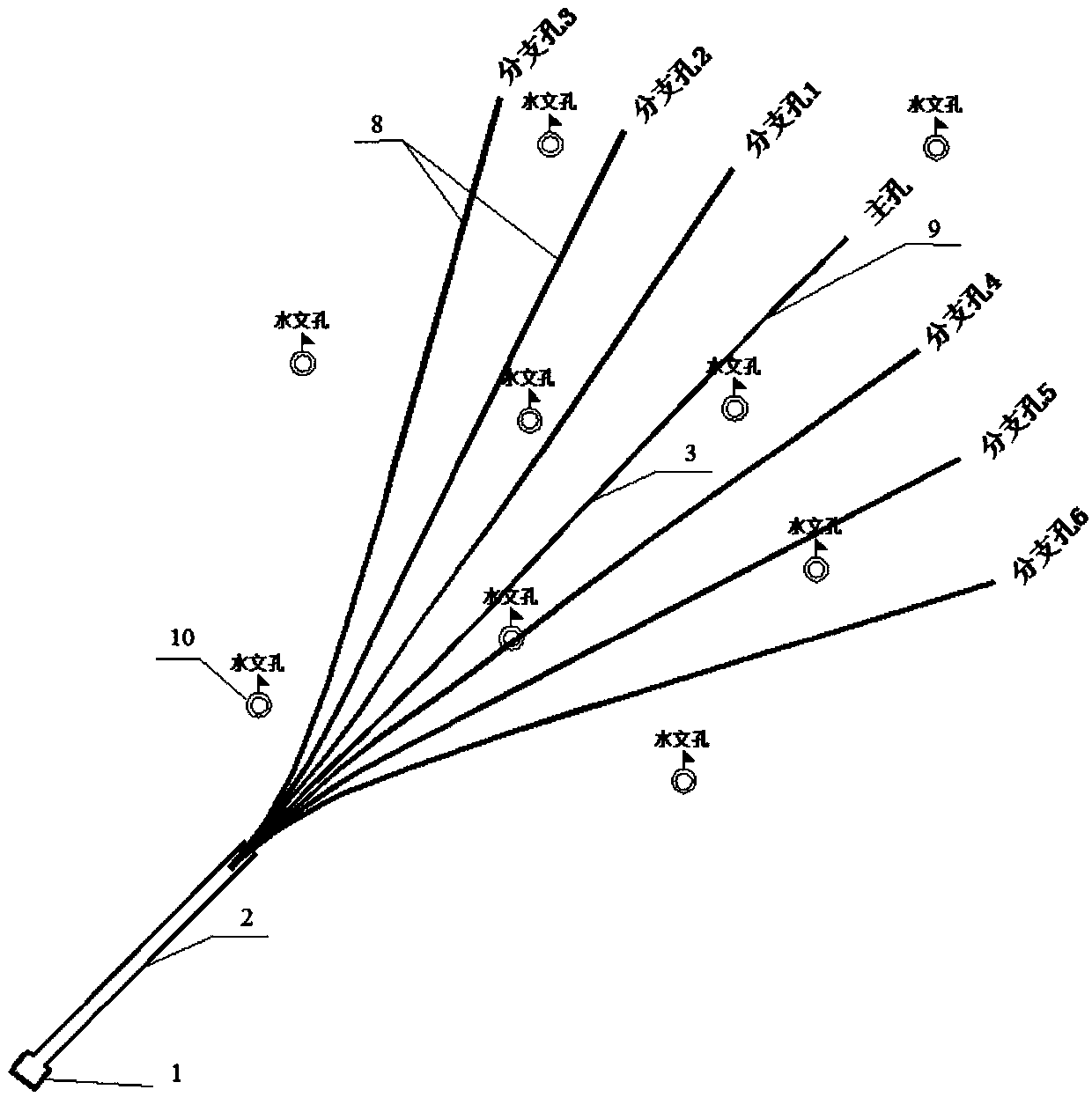

[0035] Directional drilling includes main hole [9] and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com