Switch constant current controller and switch constant current power supply drive circuit

A technology of flow controller and constant current power supply, applied in the field of switching power supply control, can solve the problems of controller failure, controller reference voltage, current offset, constant current performance degradation, etc., to reduce the offset and reduce the conduction. turn-on time, the effect of eliminating turn-on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

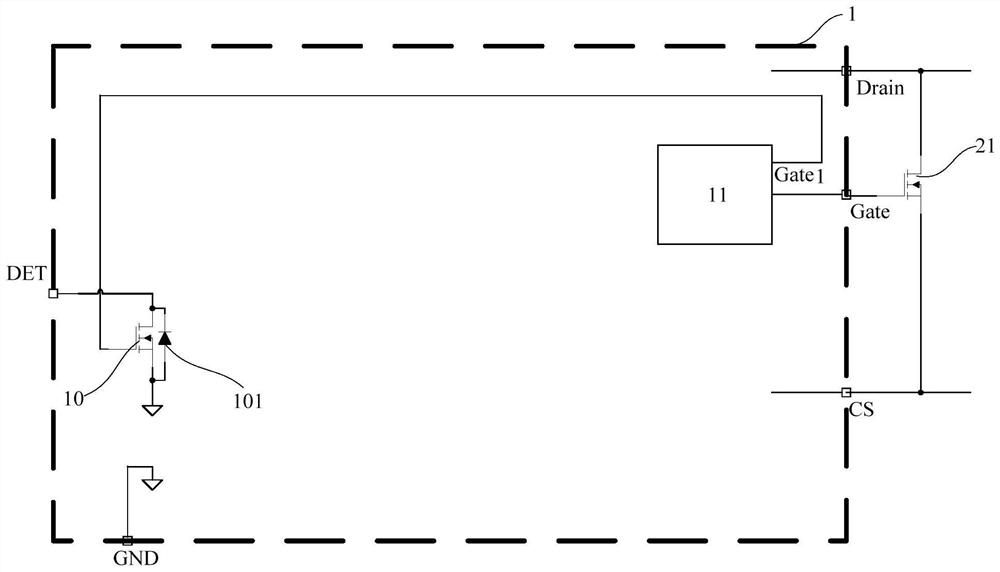

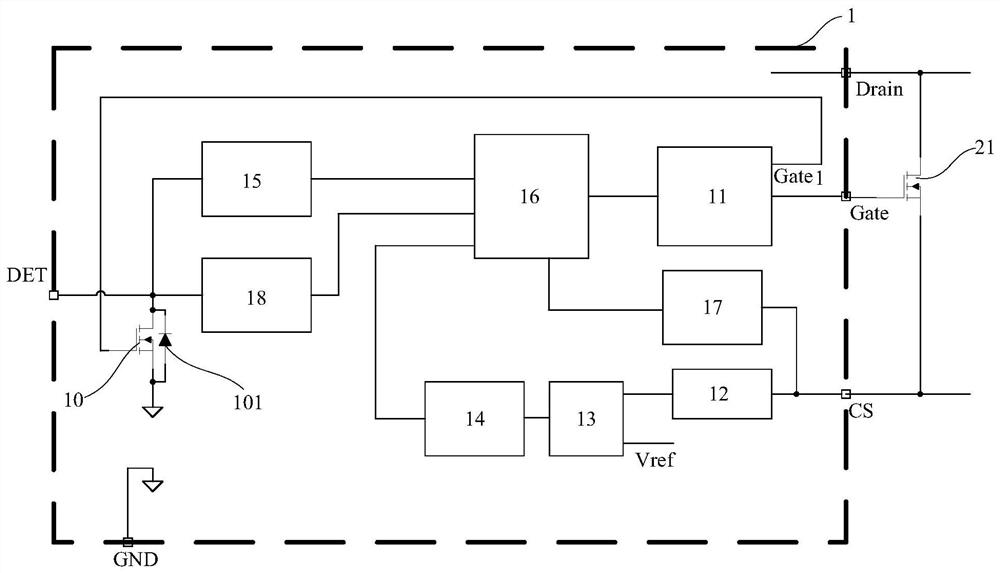

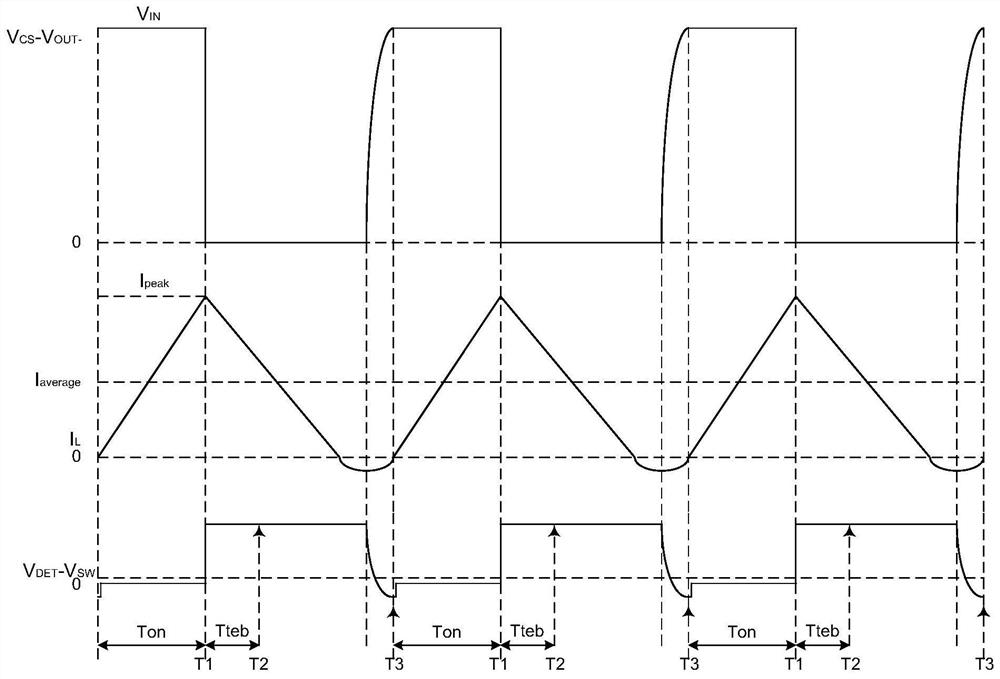

[0064] see figure 1 , the present invention provides a switch constant current controller 1, the switch constant current controller 1 at least includes: an output voltage detection pin DET, a ground pin GND, a gate pin Gate, a drain pin Drain, an electrostatic discharge pin Device 10 and drive module 11; wherein, the gate pin Gate is connected to the gate of an external power switch tube 21; the drain pin Drain is connected to the drain of the power switch tube 21 The electrostatic discharge device includes an NMOS transistor 10, the source of the NMOS transistor 10 is grounded, and the drain of the NMOS transistor 10 is connected to the output voltage detection pin DET; the drive module 11 is connected to the The gate of the NMOS transistor 10 is connected to the gate pin Gate, and is used to control the power switch 21 and the NMOS transistor 10 to be turned on or off at the same time, so as to ensure that the output voltage When the voltage at the detection pin DET is nega...

Embodiment 2

[0077] see Figure 4 , the present invention also provides a switching constant current power supply driving circuit, the switching constant current power supply driving circuit at least includes: a switching constant current controller 1 as described in Embodiment 1, a voltage input module 3 and a main circuit 2, wherein For the specific structure of the switch constant current controller 1, please refer to Embodiment 1, which will not be repeated here; the voltage input module 3 is connected to the drain of the power switch tube 21 for providing The constant current controller 1 and the main circuit 2 provide input voltage; the main circuit 2 is connected with the voltage input module 3 and the switch constant current controller 1 for generating constant current drive.

[0078] As an example, the voltage input module 31 includes an AC power supply 31, a fuse 32, and a rectification and filtering unit 33, and the AC power supply 31 and V ACL and V ACN The two input ends are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com