Bearing for a crusher, and crusher

A crusher, gyratory crusher technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as expensive maintenance of crusher downtime, bearing damage, etc., to achieve the effect of increasing the effective load bearing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

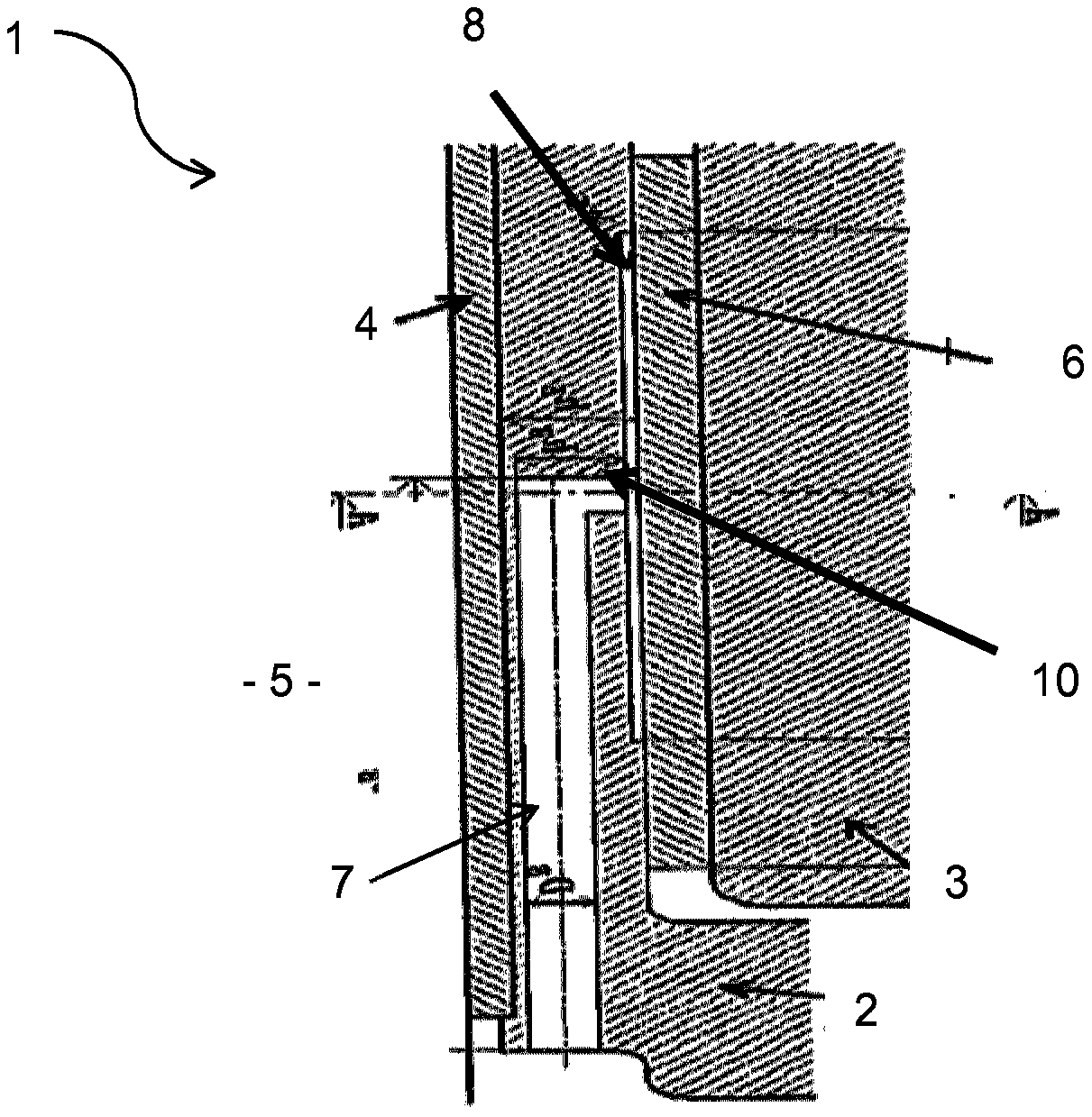

[0022] In the various figures, identical components are always provided with the same reference numerals and are therefore usually also named or mentioned only once in each case.

[0023] figure 1 A section extending parallel to the axial direction shows a bearing 1 for a crusher, in particular a slide bearing, according to an exemplary embodiment of the invention. A crusher is basically understood to mean a machine provided for crushing agglomerated material, especially rock, to form smaller particle sizes. Specifically, it is a cone crusher or a gyratory crusher. Here, comminution takes place in an annular gap that opens and closes in a cyclical manner between the crusher housing (not shown) and the crusher cone (not shown). Here, the opening and closing of the annular gap takes place simultaneously on opposite sides of the crushing space. In order to achieve the relative movement between the crusher housing and the crusher cone (this relative movement is the reason for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com