A flexible core-pulling device for a numerically controlled pipe bender

The technology of a core pulling device and a pipe bending machine is applied in the field of numerical control pipe bending devices, which can solve the problems of difficulty in debugging a mold, difficulty in installing a core mold, poor flexibility of the core pulling device, etc., so as to shorten the time for installing the core mold and improve the forming quality. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

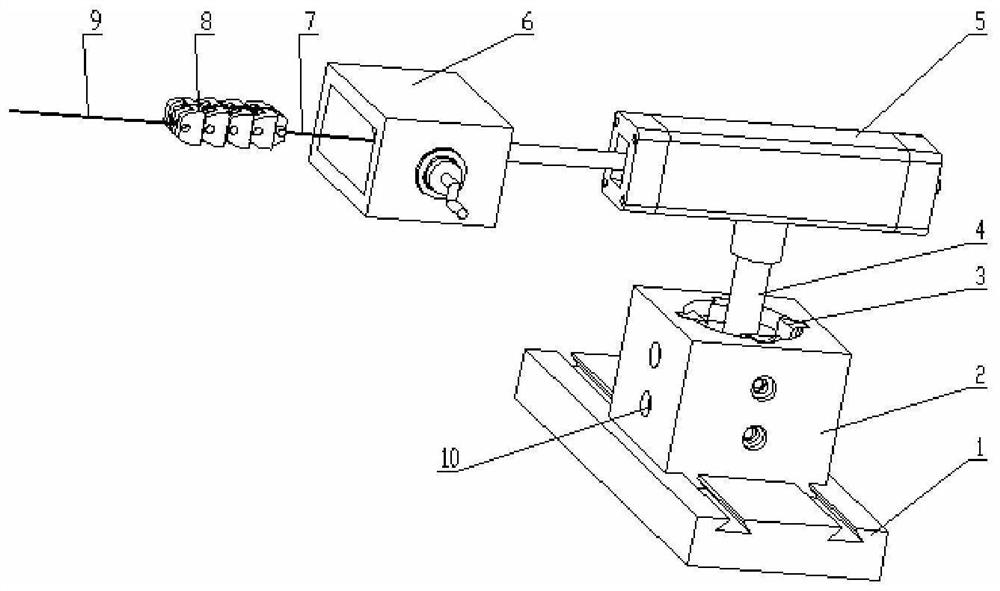

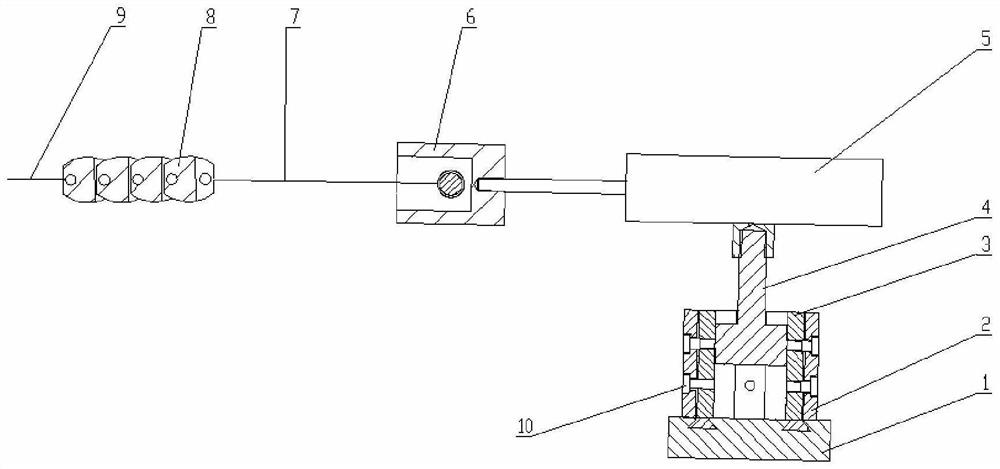

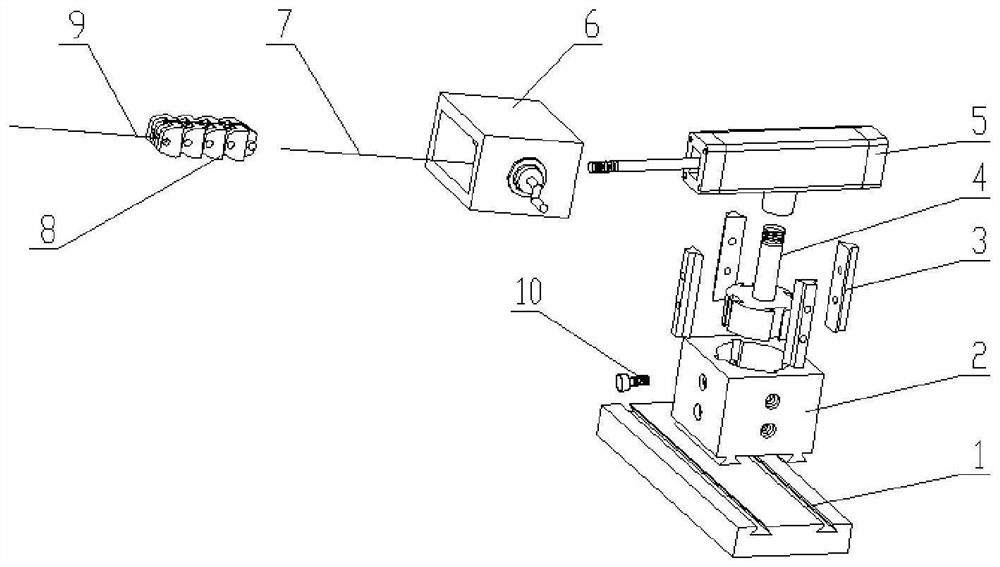

[0028]This embodiment is a core-pulling device for a flexible pipe bend mandrel, including a chute 1, a sliding sleeve 2, a guide post 3, a sliding shaft 4, a plunger-type hydraulic cylinder 5, a wire rope fixing box 6, a wire rope 7, a core Die 8 and mandrel guide rope 9. Wherein: the sliding sleeve 2 is placed in the chute 1 on the upper surface of the base of the CNC pipe bending machine through a pair of slideways located on the lower surface of the sliding sleeve. The sliding end of the sliding shaft 4 is located in the inner hole of the sliding shaft. The four guide posts 3 are respectively installed in the guide post fixing grooves on the inner surface of the sliding sleeve, and fixed by screws 10; , the working surfaces of each guide post are respectively embedded in the guide post grooves uniformly distributed on the outer circumferential surface of the sliding shaft, and the working surfaces of each guide post are friction-fitted with the inner surface of the guide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com