Robot gripper compatible with two different top covers

A technology of robot gripper and top cover, applied in the directions of manipulators, conveyor objects, chucks, etc., can solve the problem of extra robot gripper costs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

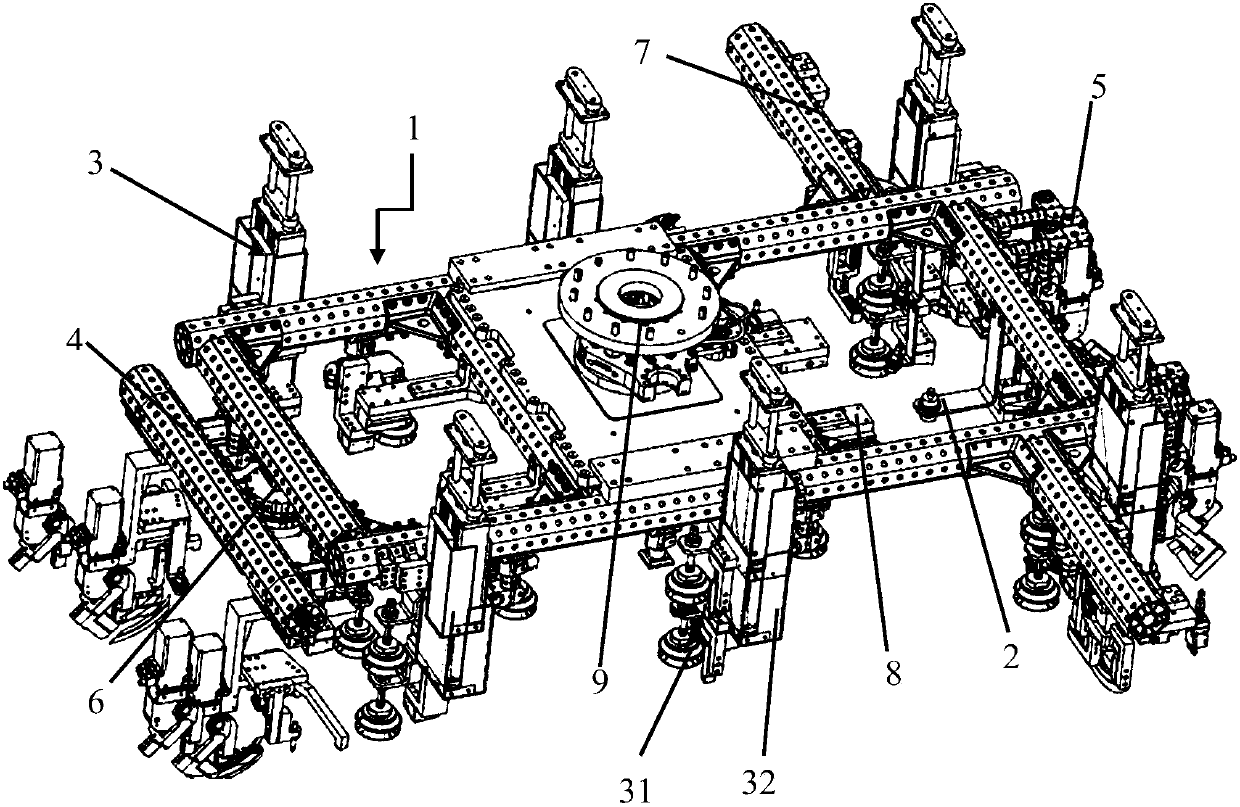

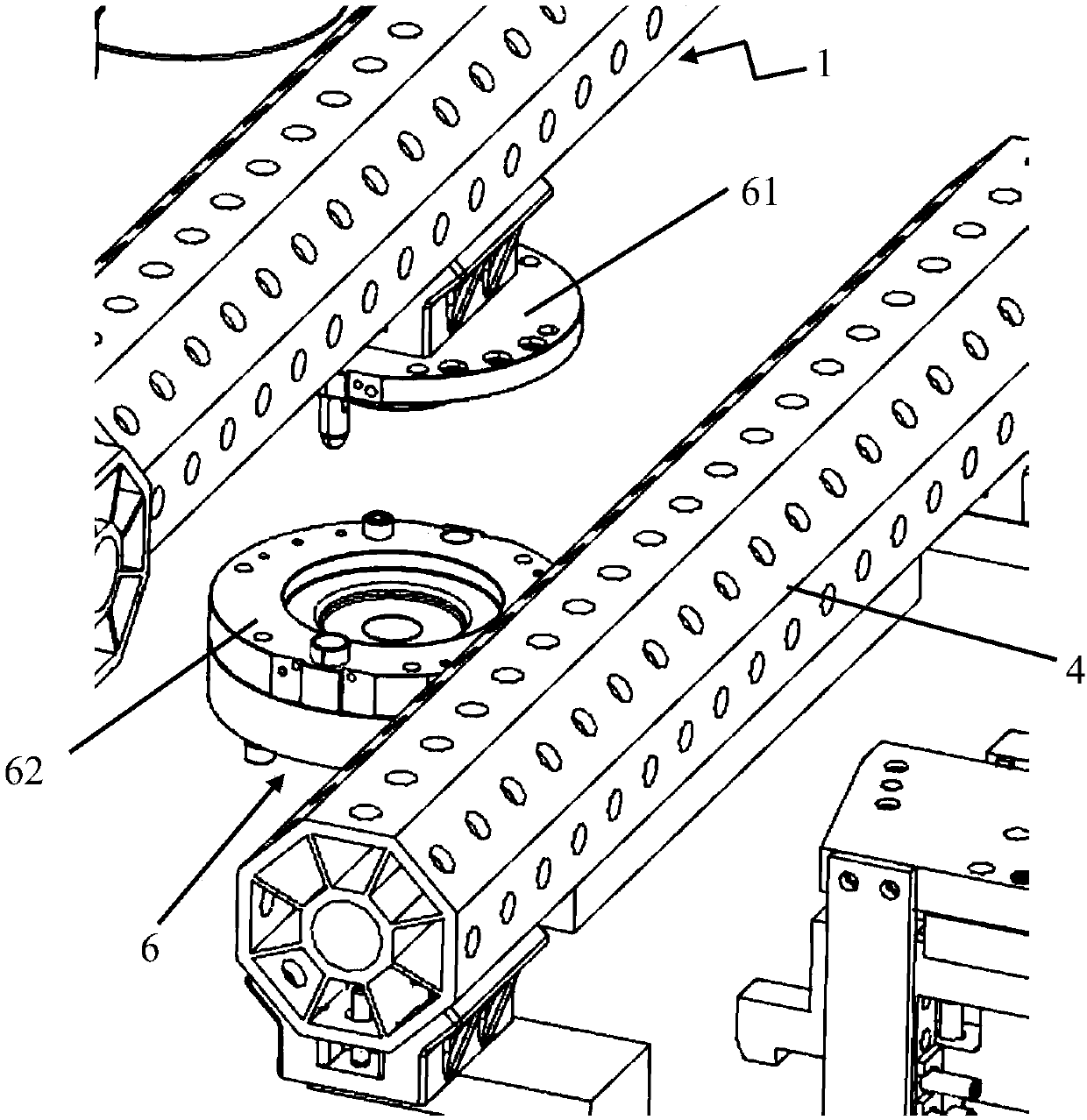

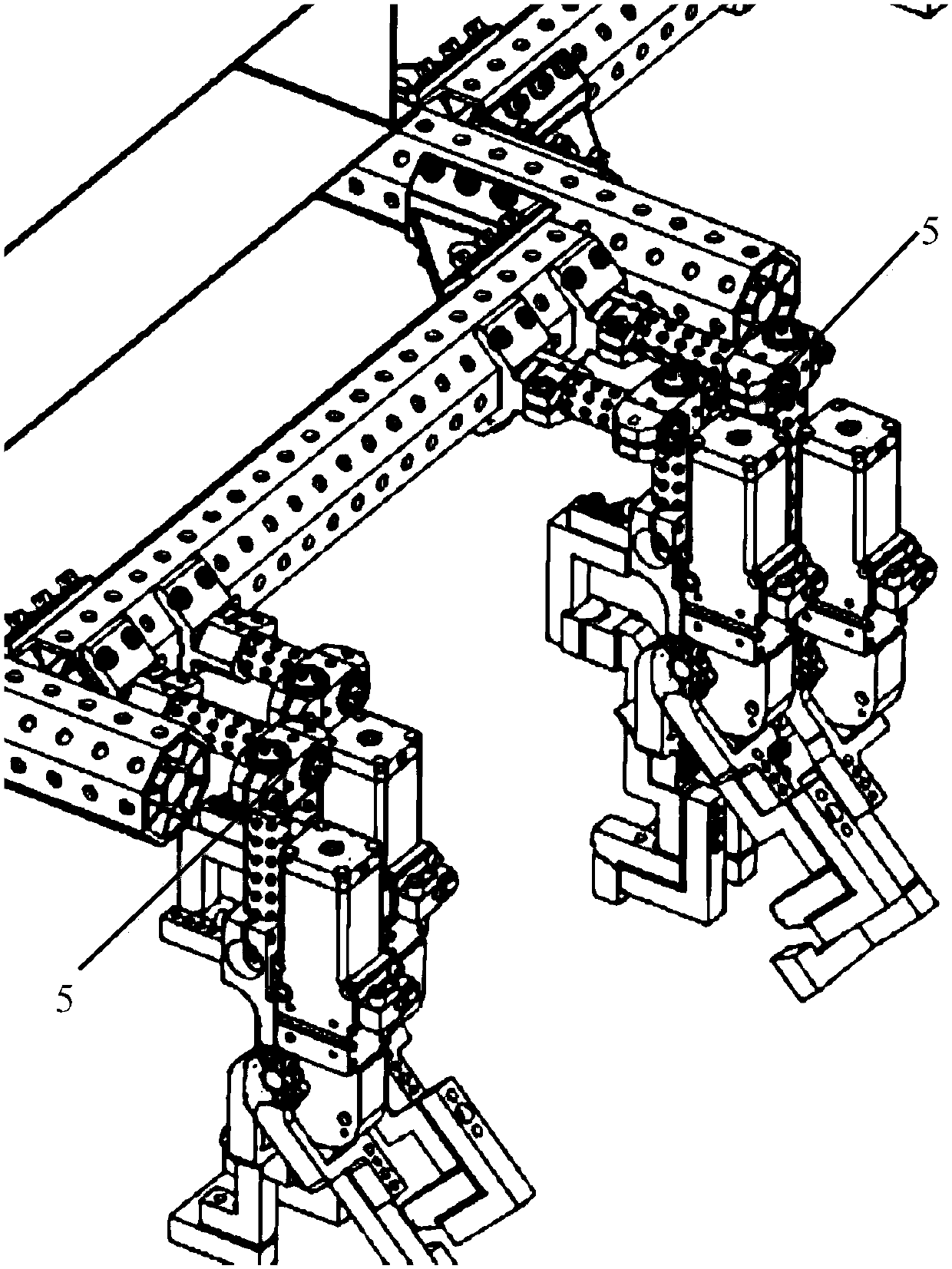

[0022] The following with attached Figure 1 to Figure 4 A robot gripper compatible with two different top covers of the present invention will be further described in detail. figure 1 The upper middle is the front, the lower is the rear, the left is the left and the right is the right.

[0023] A robot gripper compatible with two different top covers of the present invention, please refer to Figure 1 to Figure 4 Relevant figures include a gripper frame 1, a clamping device, a car model in-position detection sensor 2 and at least six sets of suction cup high-low position switching devices 3, and the clamping device is detachably fixedly connected to the left side of the gripper frame 1 and On the right side of the gripper frame 1, the car model in-position detection sensor 2 is fixedly connected inside the gripper frame 1, and the car model in-position detection sensor 2 is connected to the clamping device and the suction cup high-low position switching device 3. Communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com