Method for producing gasoline and diesel oil by catalyst grading technology

A catalyst and catalyst bed technology, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of catalyst process improvement, long catalyst operation period, single raw material selection range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

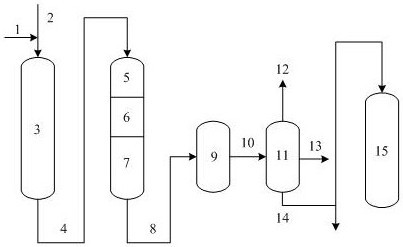

[0040] use figure 1 In the combined process flow shown, straight-run wax oil is selected as the raw material for hydrogenation to produce gasoline and diesel oil, and certain refining (nitrogen content 100ppm) and conversion depth (gasoline yield is about 10%) are controlled to a certain extent. The diesel yield in the hydrogenation upgrading process is It is 96wt%. The catalysts used in the examples are the commercial catalyst FF-36 hydrotreating catalyst, the special hydroconversion catalyst A, the commercial catalyst FC-18 hydrogenation upgrading catalyst and the C single-ring aromatic hydrocarbon retaining hydroconversion catalyst.

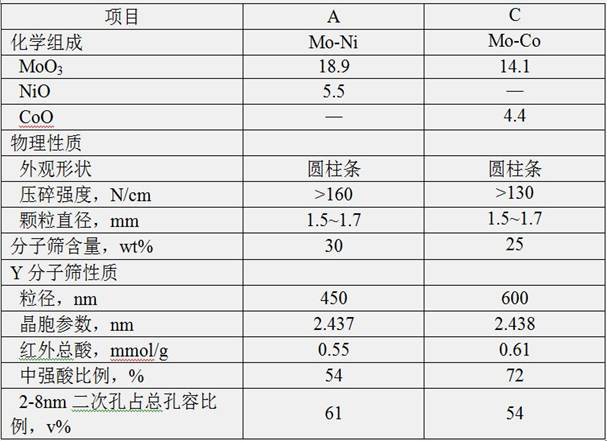

[0041] The properties of catalysts A and C are shown in Table 1, the properties of feed oil are shown in Table 2, and the operating conditions are shown in Table 3.

Embodiment 2

[0043]use figure 1 In the combined process shown, straight-run wax oil is selected as the raw material for hydrogenation to produce gasoline and diesel, and a certain refining (nitrogen content of 200ppm) and conversion depth (gasoline yield is about 10%) is controlled to a certain extent. It is 96wt%. The catalysts used in the examples are commercial catalyst FF-36 hydrotreating catalyst, special hydroconversion catalyst A, commercial catalyst FC-18 (hydrogenation upgrading catalyst) and single-ring aromatics retained hydroconversion catalyst C.

[0044] The properties of catalysts A and C are shown in Table 1, the properties of feed oil are shown in Table 2, and the operating conditions are shown in Table 3.

Embodiment 3

[0046] use figure 1 In the combined process flow shown, straight-run wax oil is selected as the conversion raw material for hydrogenation to produce gasoline, and certain refining (nitrogen content 200ppm) and conversion depth (gasoline yield is about 5%) are controlled to a certain extent. The diesel yield in the hydrogenation upgrading process is It is 96wt%. The catalysts used in the examples are the commercial catalyst FF-36 hydrotreating catalyst, the special hydroconversion catalyst A, the commercial catalyst FC-18 hydrogenation upgrading catalyst and the C single-ring aromatic hydrocarbon retaining hydroconversion catalyst.

[0047] The properties of catalysts A and C are shown in Table 1, the properties of feed oil are shown in Table 2, and the operating conditions are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com