Aloft construction platform and box girder bridge constructing method

A construction platform and high-altitude operation technology, which is applied in bridge construction, bridges, buildings, etc., can solve the problems of affecting traffic under the platform, small operating space, and strong platform stability, so as to improve operating efficiency, ease of erection, and platform stability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

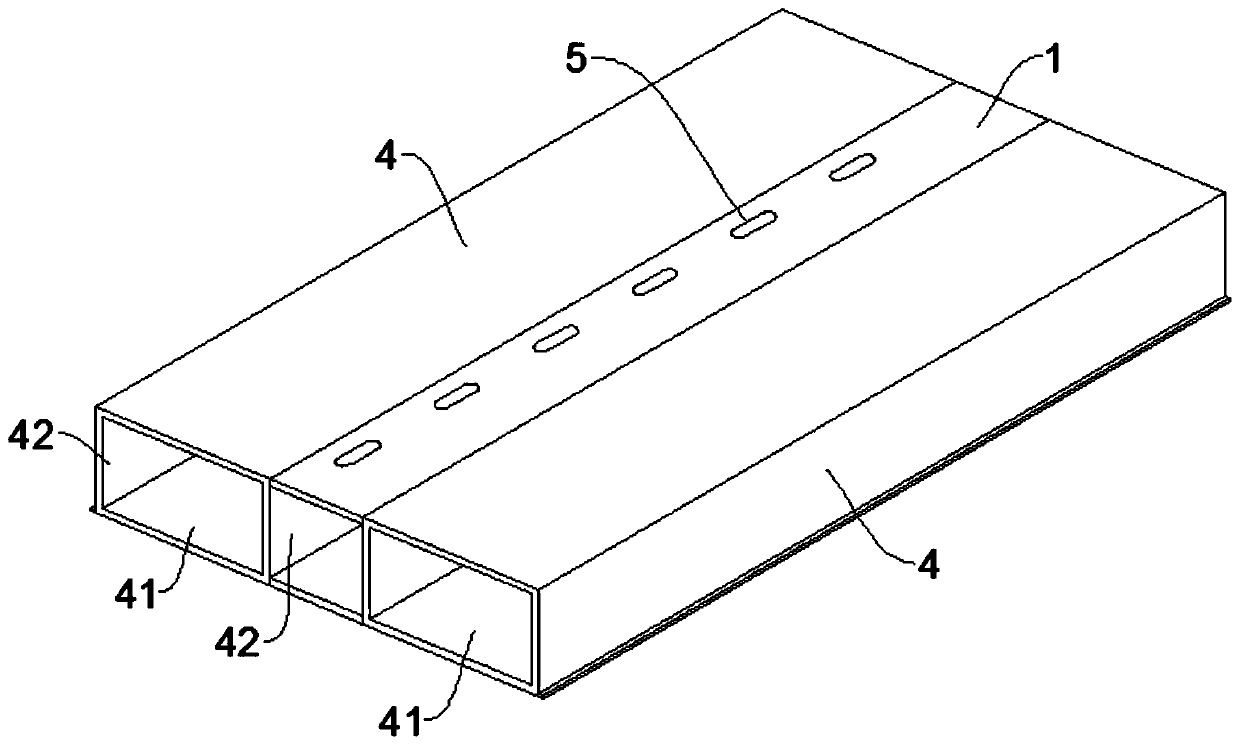

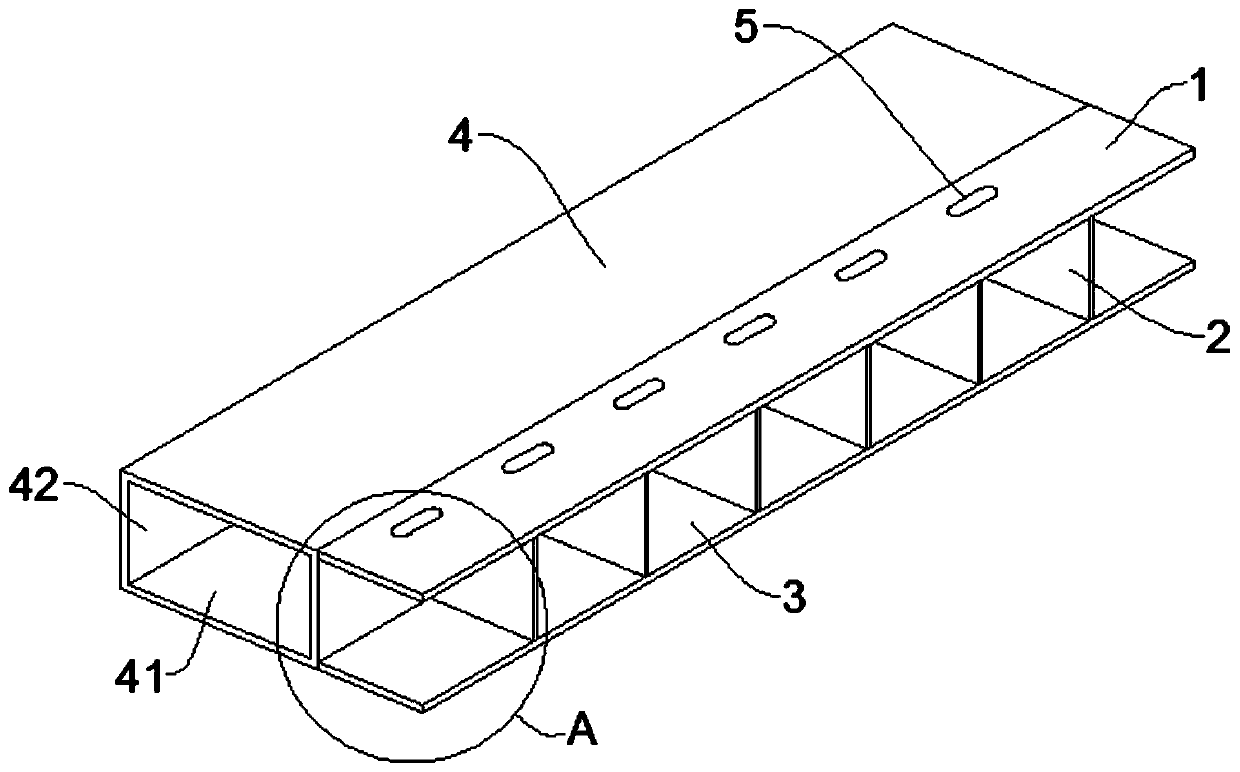

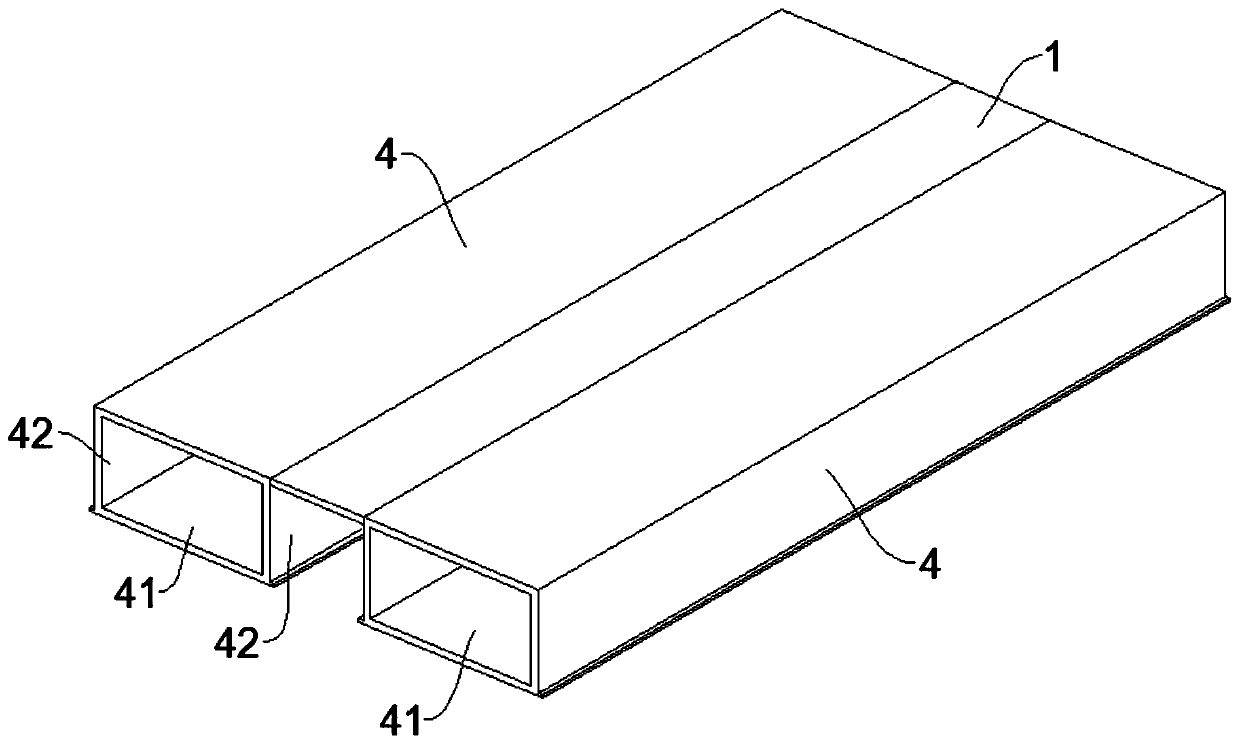

[0041] Please refer to Figure 1 ~ Figure 4 , the present embodiment provides a construction platform for aerial work, which includes a cross-link steel plate 1, at least two barrier steel plates 2 and at least one bracket 3; Between the box girders 4, the two sides in the width direction of the cross-link steel plate 1 are respectively used to weld the cover plates of the two box girders 4; The lower side of the steel plate 1, and any partition steel plate 2 extends along the width direction of the cross-connected steel plate 1; a bracket 3 is arranged between any two adjacent partition steel plates 2, and the bracket 3 and the cross-connected steel plate 1 Relatively arranged; the barrier steel plate 2, the bracket 3 and the cross-connection steel plate 1 are used to form a rectangular tube with openings at both ends; the cross-connection steel plate 1 is provided with a manhole 5 between any two adjacent barrier steel plates 2 . Preferably, the manhole 5 is designed as an ...

no. 2 example

[0048] Please refer to Figure 1 ~ Figure 3 and Figure 5 , the present embodiment provides a construction platform for aerial work, which is substantially the same as the construction platform for aerial work in the first embodiment, the difference between the two is that in the construction platform for aerial work in this embodiment, the supporting plate 32 includes a plurality of strips Straight board 321; a plurality of straight boards 321 are arranged side by side.

[0049] Please refer to Figure 5 , the above-mentioned strip-shaped straight plate 321 is provided with an anti-slip texture 322 on one side away from the cross bar 31 .

[0050] In the above-mentioned embodiment, 1. The supporting plate 32 is designed as a structure in which a plurality of strip-shaped straight plates 321 are assembled side by side, which is also beneficial for putting the supporting plate 32 into and taking out from the manhole 5 in parts. 2. Due to working at heights, the anti-skid lin...

no. 3 example

[0052] This embodiment provides a method for building a box girder 4 bridge using the above-mentioned high-altitude operation construction platform, including the following steps:

[0053] Step 1: welding a cross-connected steel plate 1 between any two adjacent box girders 4;

[0054] Step 2: Construction personnel enter above the bracket 3 through the manhole 5, and weld and fix any two adjacent box girders 4 through the barrier steel plate 2.

[0055] The construction method of the box girder 4 bridge in this embodiment: the above-mentioned high-altitude operation construction platform is used to build the box girder 4 bridge, which can provide a stable and easy-to-build construction platform without affecting the normal traffic under the bridge. Improve the efficiency of bridge construction.

[0056] Further, after the above step 1, the bracket 3 is placed under the horizontal steel plate 1 through the manhole 5 , and the bracket 3 is installed between the two barrier stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com