Magnetic rotor type material detection device and method

A material detection, rotor-type technology, used in measuring devices, liquid level indicators for physical variable measurement, liquid/fluid solid measurement, etc., can solve the problems of easy damage, low sensitivity, poor safety, etc. The effect of high sensitivity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

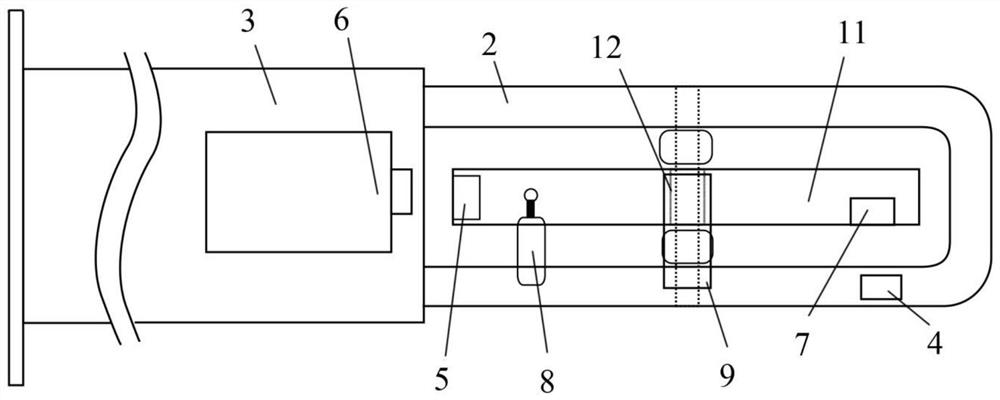

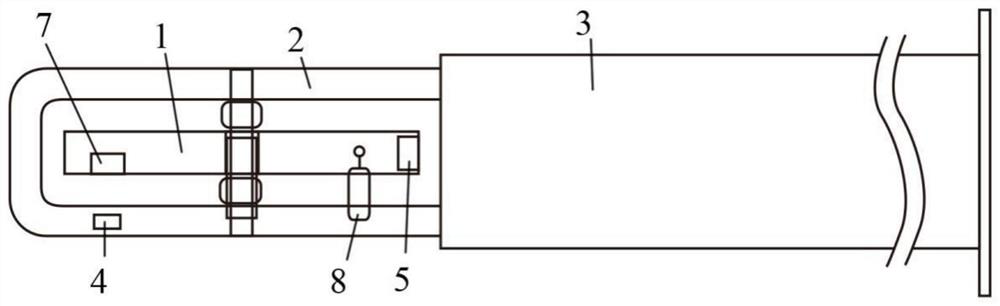

[0059] Such as Figure 5-1 As shown, the magnetic rotor 1 is a straight rod, the shaft hole 12 is set in the middle of the rod, both ends are permanent magnets, and the signal receiver 4 is a magnetic sensor. Whenever the magnetic sensor is triggered twice, the magnetic rotor 1 rotates once.

example 2

[0061] Such as Figure 5-2 As shown, the magnetic rotor 1 is a cross-shaped rod, the shaft hole 12 is set in the middle of the rod, the four ends are permanent magnets, and the signal receiver 4 is a magnetic sensor. Whenever the magnetic sensor is triggered four times, the magnetic rotor 1 rotates once.

example 3

[0063] Such as Figure 5-3 As shown, the magnetic rotor 1 is a disc with 4 permanent magnets evenly distributed on the outer edge of the disc, the signal transmitter 7 is a laser transmitter, and the signal receiver 4 is a laser receiver. Whenever the laser receiver is triggered 4 times, The magnetic rotor 1 rotates once.

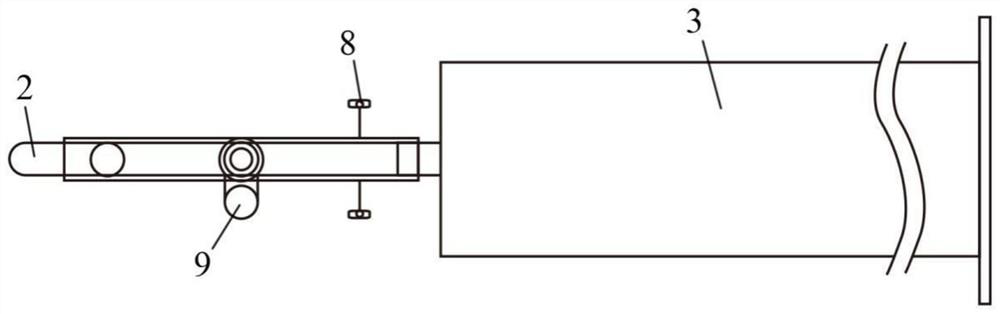

[0064] Although the magnetic rotor 1 can both rotate and swing, if only one magnetic field receptor 5 is provided, the magnetic rotor 1 may have a motion dead point when it rotates to the farthest distance between the magnetic field receptor 5 and the magnetic field generator, and then the Magnetic rotor 1 is stuck. In order to avoid the above situation, in the embodiment of the present invention, the mounting bracket 2 is provided with a limit rod 9, which can make the magnetic rotor 1 only swing but not rotate. When the magnetic rotor 1 moves towards the dead point position in the above situation, the limit The position rod 9 can prevent the magnetic ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com