A cable trench cover

A cable trench cover plate and steel plate technology, applied in the field of substation maintenance, can solve the problems of inconvenient manual handling, low safety factor, inconvenient opening, etc., and achieve the effect of enhancing the bonding force, reducing the weight and ensuring the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

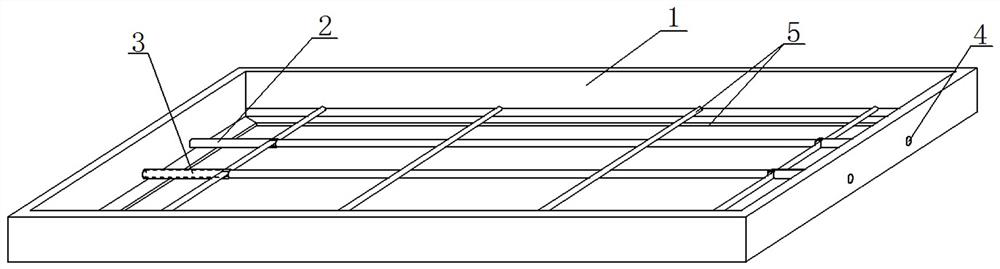

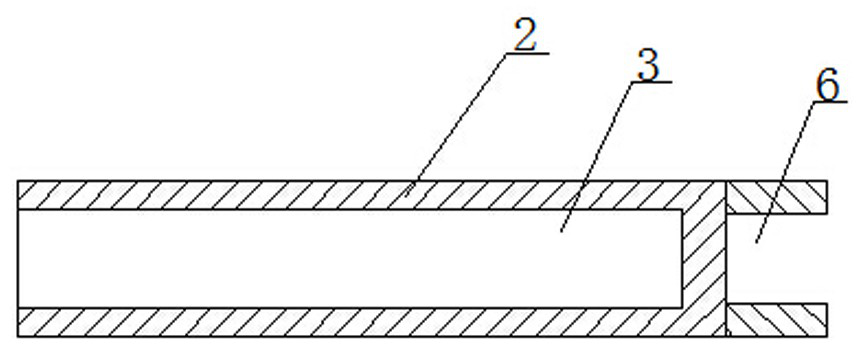

[0025] The invention discloses a cable trench cover plate, the specific results are as follows Figure 1-2 As shown, frame 1 is included, wherein frame 1 is a square frame welded by four L-shaped steel plates, the L-shaped steel plate in the present invention is a galvanized angle iron, and the inner wall of frame 1 short side is symmetrically welded steel pipe 2, and steel pipe 2 is Hollow structure, with a through hole 3 inside, and a round hole 4 connected to the steel pipe 2 on the short side of the frame 1, and a steel bar 5 at the bottom of the frame 1, where the steel bar 5 is arranged at the bottom of the frame 1, and the long side of the frame 1 is uniform Four steel bars 2 are welded. The front end of the steel pipe 2 is provided with a slot 6. The steel bars 5 welded on both sides of the long side of the frame 1 pass through the slot 6. The top of the steel tube 2 corresponds to the welded steel bar 5. The distribution of the steel bars is as follows: figure 1 shown...

Embodiment 2

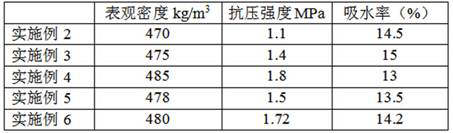

[0029] In order to reduce the weight of the cable trench cover plate of the present invention and ensure the strength simultaneously, the present invention improves the formula of the concrete filled in the cover plate, specifically:

[0030] The concrete is lightweight concrete, which is mixed with the following raw materials in parts by weight: 10 parts of Portland cement, 3 parts of silica fume, 8 parts of fly ash, 4 parts of acrylic fiber, 3 parts of calcium sulfate whiskers, styrene-butadiene rubber 2 parts of powder, 2 parts of styrene-acrylic emulsion, 9 parts of water, 0.1 part of foaming agent, 2 parts of sodium silicate, and 0.5 part of thickener.

[0031] Wherein the acrylic fiber has a diameter of 15-20 μm and a length of 1-3 mm, and a calcium sulfate whisker has a diameter of 1-8 μm and a length of 100-200 μm.

[0032] The thickener is a mixture of hydroxypropyl methylcellulose and polyethylene glycol in a weight ratio of 1:1.

[0033] The foaming agent is formed...

Embodiment 3

[0036] The difference between this embodiment and embodiment 2 is:

[0037] The concrete is lightweight concrete, which is mixed with the following raw materials in parts by weight: Portland cement 10.5 parts, silicon fume 3.5 parts, fly ash 7 parts, acrylic fiber 4 parts, calcium sulfate whiskers 2.5 parts, styrene-butadiene rubber 2.5 parts of powder, 2 parts of styrene-acrylic emulsion, 9 parts of water, 0.15 parts of foaming agent, 2.2 parts of sodium silicate, and 0.4 parts of thickener.

[0038] Wherein the acrylic fiber has a diameter of 15-20 μm and a length of 1-3 mm, and a calcium sulfate whisker has a diameter of 1-8 μm and a length of 100-200 μm.

[0039] The thickener is a mixture of hydroxypropyl methylcellulose and polyethylene glycol in a weight ratio of 1:1.

[0040] The foaming agent is formed by mixing animal protein foaming agent and sodium dodecylsulfonate in a weight ratio of 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com