Operating elements for electrically controlled machines

A technology of operating components and electric control, applied in the direction of control mechanisms, control components, electrical components, etc., can solve problems such as expensive, difficult to achieve coupling, and easy to fail in coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

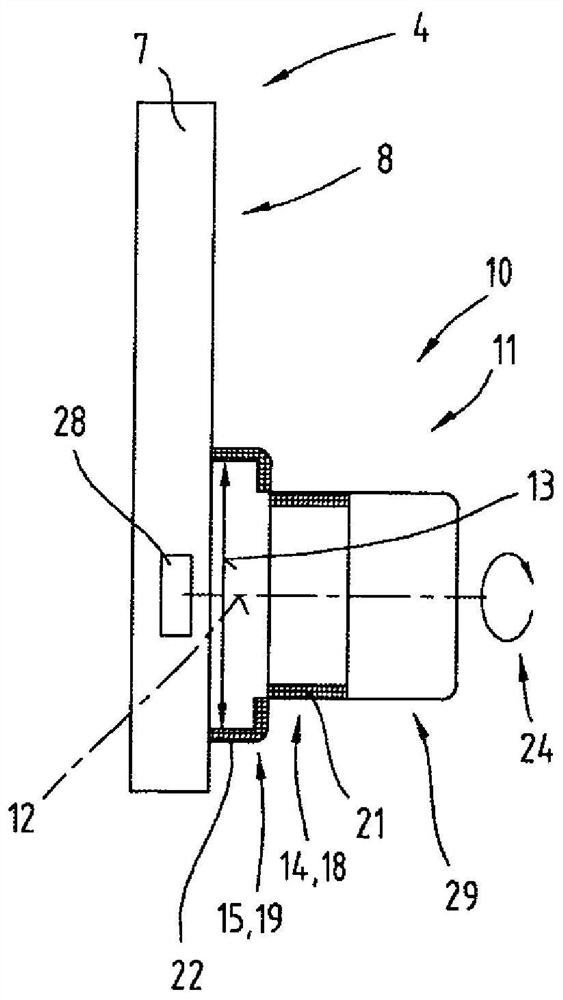

[0047] First of all, it should be pointed out that in the different described embodiments, the same components are provided with the same reference numerals or the same component names, wherein the disclosure contained in the entire specification can be transferred to those with the same reference numerals. Symbols or on the same part with the same component name. The position descriptions selected in the description, such as upper, lower, lateral, etc., also refer to the directly described and illustrated figures and these position descriptions are transferred meaningfully to the new position when the position is changed.

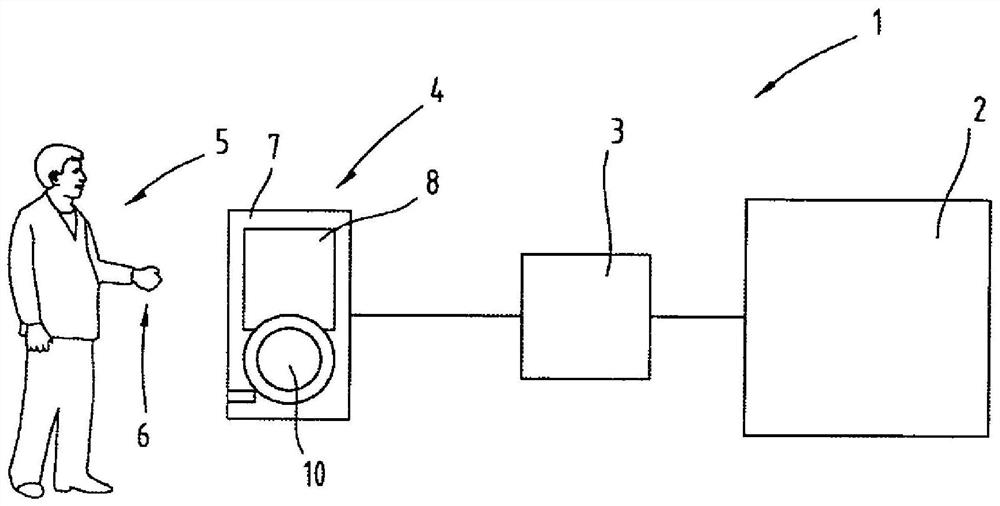

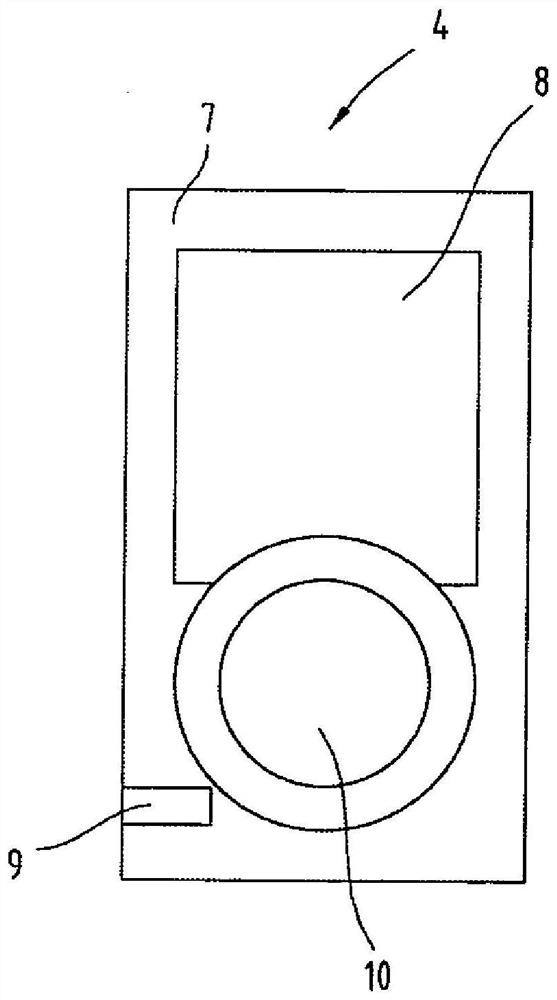

[0048] figure 1 A schematic diagram of a production plant 1 is shown with an electrically controlled machine 2 , a control device 3 for the machine 2 and operating elements 4 for inputting control commands into the control device 3 by a machine operator 5 . In particular, provision is made for the machine operator 5 to actuate the operating element 4 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com