3D printing integrally formed ankle foot orthosis and manufacturing method thereof

An ankle-foot orthosis, 3D printing technology, applied in manufacturing auxiliary devices, medical science, processing data acquisition/processing, etc., can solve the inconvenience of ankle-foot orthosis, lack of comfort and orthopedic effect, orthosis and Problems such as poor fit of legs and feet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

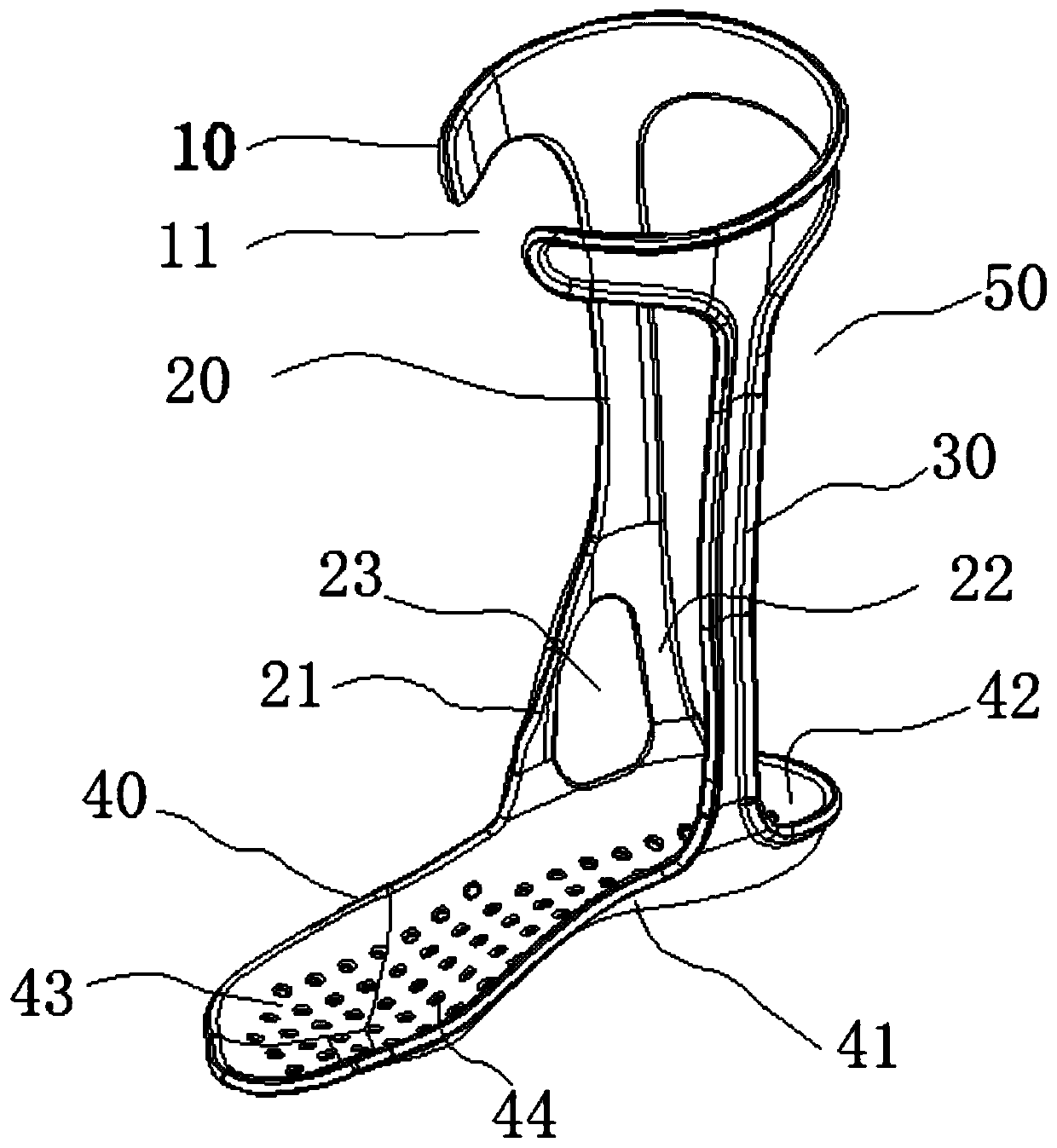

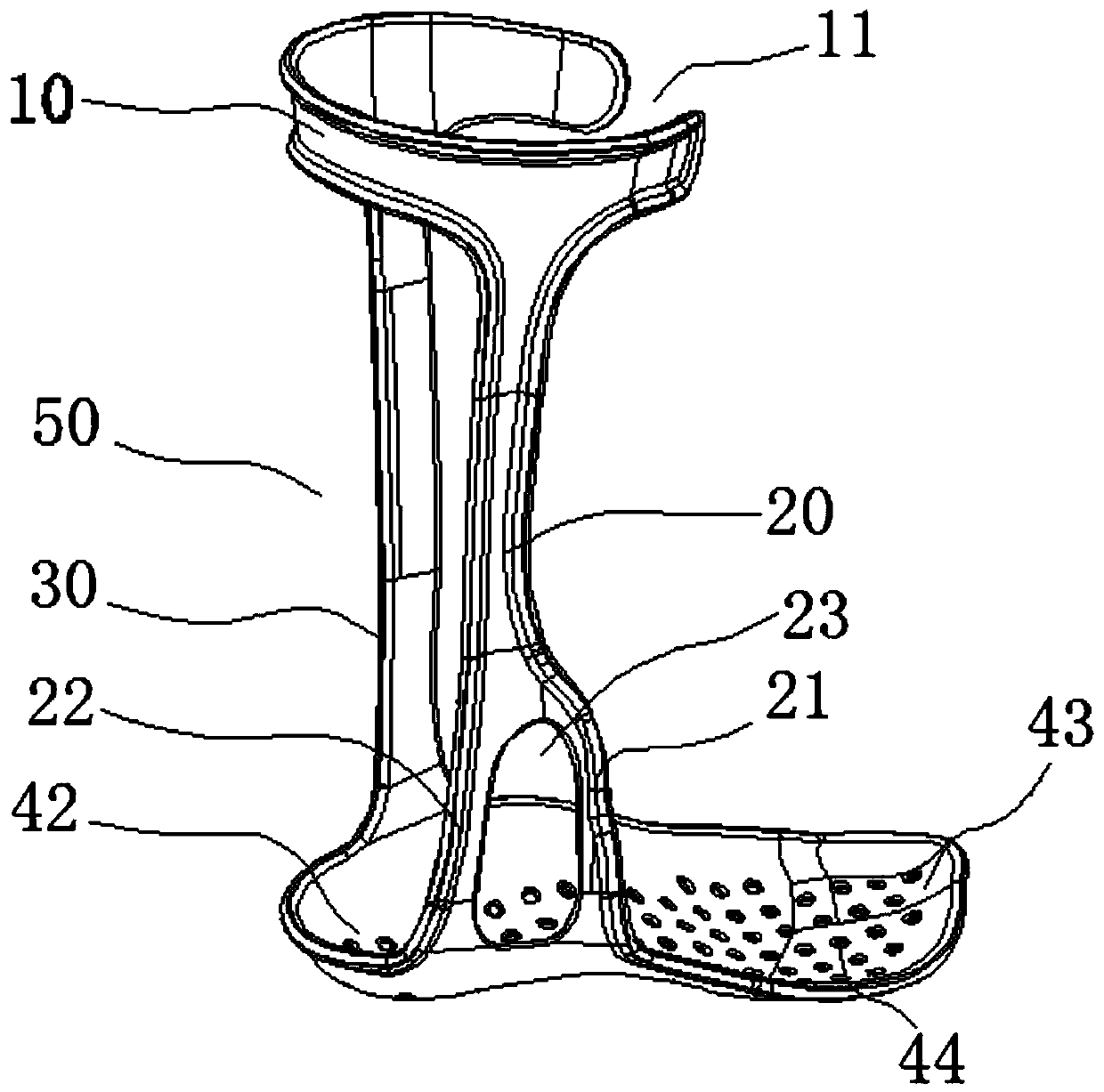

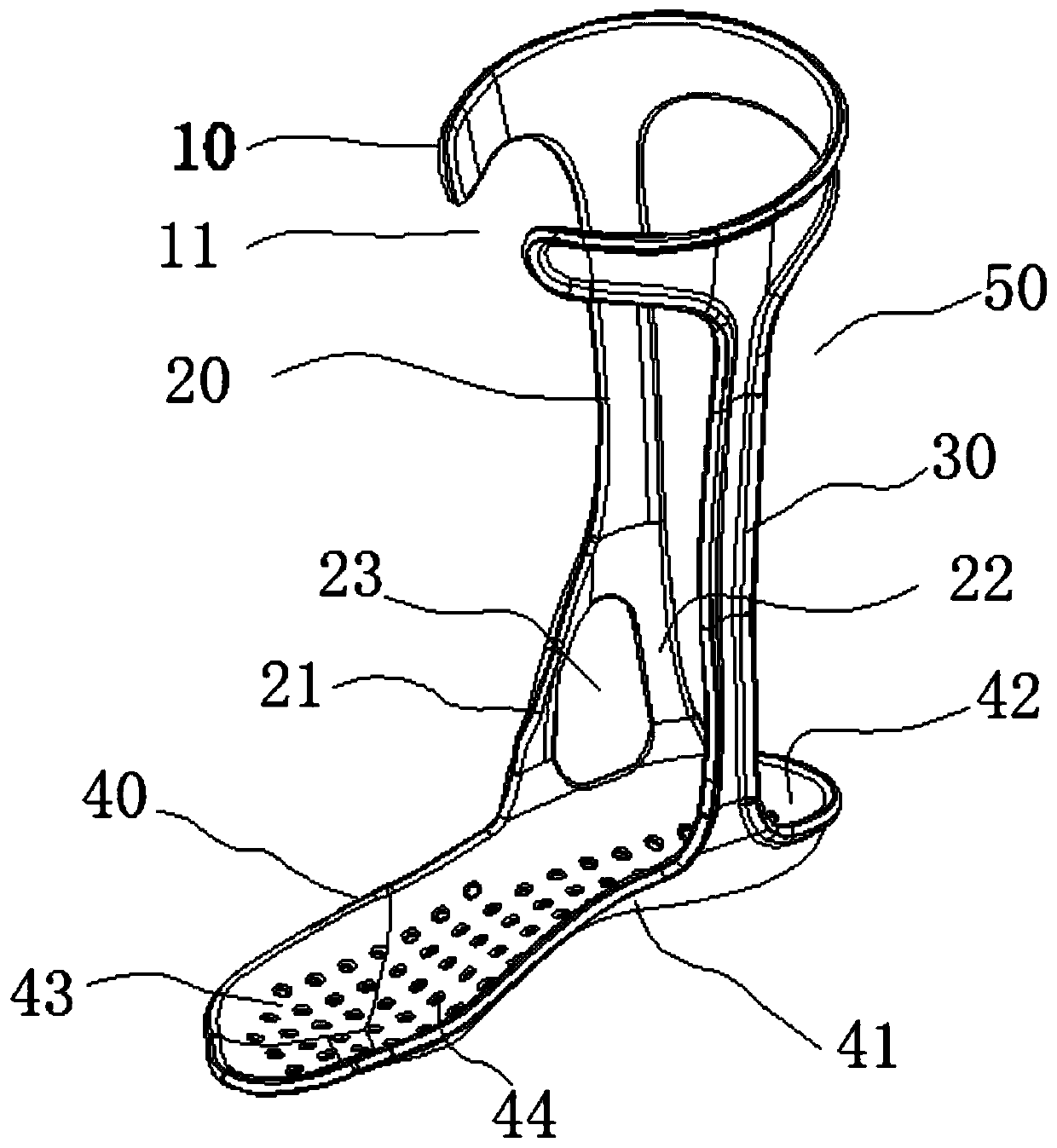

[0031] Such as figure 1 , 2 As shown, a 3D printed integrally formed ankle-foot orthosis of this embodiment includes a calf covering fixture 10, an outer support frame 20, an inner support frame 30, and a plantar orthosis 40. The outer support frame 20 The upper end of the outer support frame 20 and the inner support frame 30 are connected to the calf covering fixing member 10, and the lower end is connected to the plantar orthopedic member 40; the outer support frame 20 Separate from the joint of the plantar orthosis 40 to form a lateral malleolus front end fixture 21 and a lateral malleolus back end fixture 22, the lateral malleolus front end fixture 21 and lateral malleolus rear end fixture 22 are provided with lateral malleolus placement holes 23; The plantar orthopedic component 40 also includes an arch orthopedic area 41, a heel protection area 42, and a plantar protection area 43. The inner support frame 30 is connected to the plantar orthopedic element 40 near the arch o...

Embodiment 2

[0033] Such as figure 1 , 2 As shown, the calf covering and fixing member 10 described in this embodiment is a semi-enclosing structure provided with an opening 11, and the height is set at the maximum position of the calf gastrocnemius muscle. The calf covering and fixing member 10 wraps the largest portion of the calf gastrocnemius muscle. Cover, opening 11 facing the shin bone. The calf covering and fixing member 10, the outer support frame 20 and the inner support frame 30 jointly enclose a calf muscle group release area 50, and the calf muscle group is placed in the calf muscle group release area 50 when worn. The opening 11 provided in the calf wrap fixing member 10 can prevent the calf gastrocnemius from being over-wrapped. The calf muscle release area 50 can also avoid friction between the calf muscles and the ankle-foot orthosis, and can also achieve a ventilation effect.

Embodiment 3

[0035] Such as figure 1 , 2 As shown, the arch correction area 41, the heel protection area 42, and the sole protection area 43 described in this embodiment are all closely fitted to the curve of the human foot. The plantar orthosis 40 is also provided with a plurality of ventilation holes 44 penetrating the plantar orthosis 40. The ventilation hole 44 is used for the ventilation of the sole. The arch orthopedic area 41, the heel protection area 42, and the sole protection area 43 closely fit the curve of the human foot to achieve the orthopedic effect and achieve comfort during wearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com