Water supplying pressure controlling method and system

A pressure control and pressure technology, which is applied in the field of water supply pressure control methods and systems, can solve the problems of water supply pressure unable to meet pressure requirements and reduction of steelmaking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

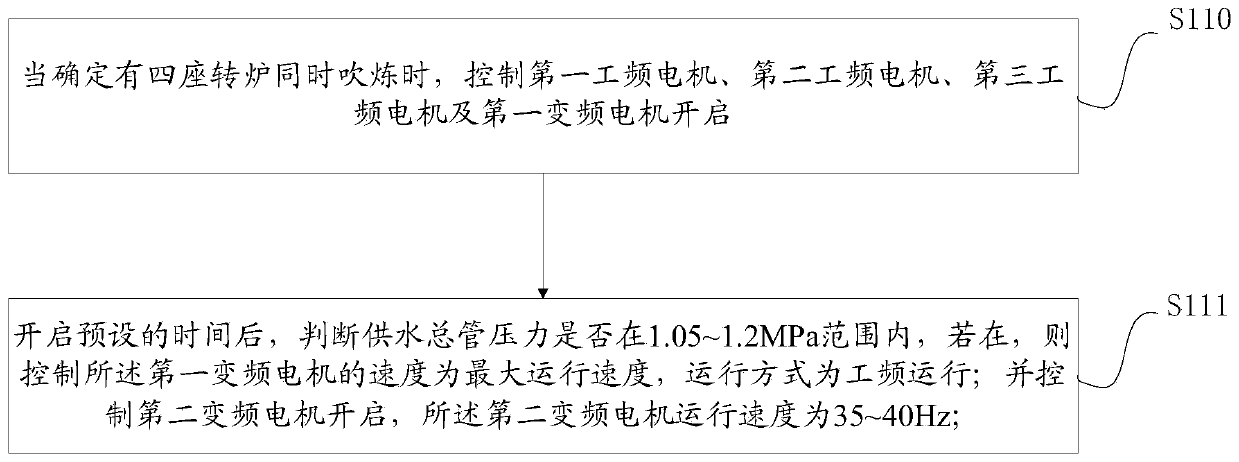

[0034] This embodiment provides a water supply pressure control method, such as figure 1 As shown, the methods include:

[0035] S110, when it is determined that there are four converters blowing at the same time, control the first power frequency motor, the second power frequency motor, the third power frequency motor and the first frequency conversion motor to start;

[0036] In this embodiment, the number of converters currently in the blowing state is determined by collecting converter blowing signals. When it is determined that there are four converters blowing at the same time, control the first power frequency motor, the second power frequency motor, the third power frequency motor and the first frequency conversion motor to start. The speed of the first variable frequency motor is 35-50 Hz.

[0037] Here, the simultaneous blowing of four converters includes two types: one is that there are always four converters in the blowing state; the other is that the blowing of ...

Embodiment 2

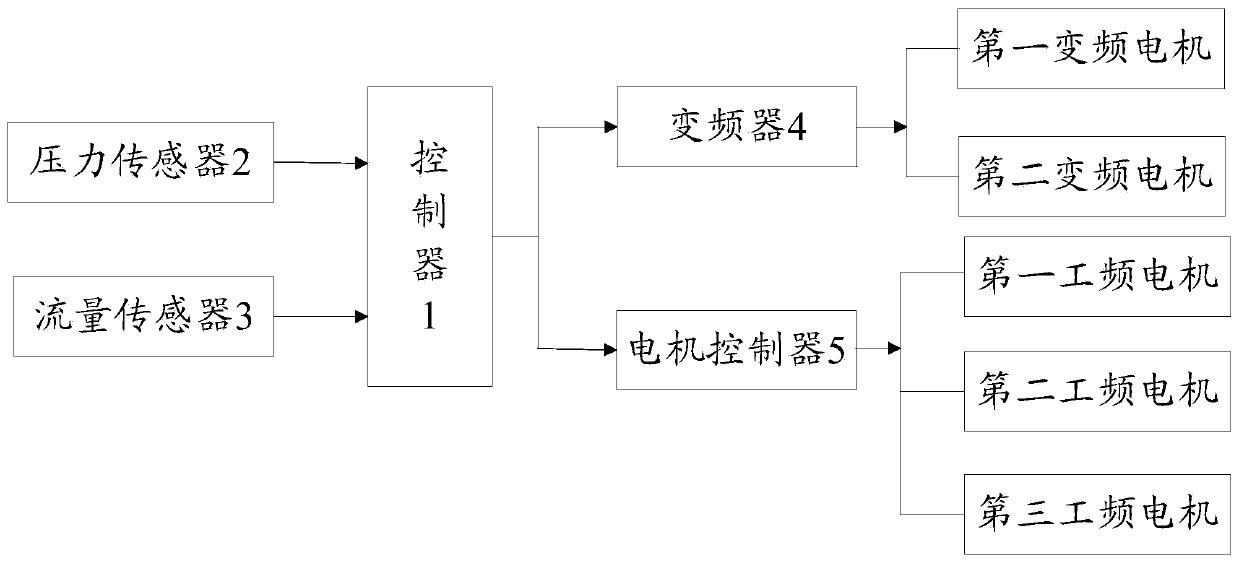

[0059] Based on the same inventive concept, this embodiment also provides a water supply pressure control system, such as figure 2 As shown, the system includes: a controller 1, a pressure sensor 2, a flow sensor 3, a frequency converter 4, a motor controller 5 and a motor 6; wherein, the controller 1 is a programmable logic controller (PLC, Programmable Logic Controller). The controller 1 establishes communication with the frequency converter 4 and the motor controller 5 through the DP network, and the pressure sensor 2 and the flow sensor 3 are connected to the analog interface of the controller 1 respectively.

[0060] In this implementation, there are five motors in total, including three power frequency motors and two variable frequency motors. The industrial frequency motor is controlled by the motor controller 5 , and the variable frequency motor is controlled by the frequency converter 5 .

[0061] As an optional embodiment, the controller 1 is configured to: determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com