Trash rack with trash cleaning grab bucket

A trash rack and pollution cleaning technology, which is applied in the direction of general water supply conservation, cleaning of open water surfaces, water conservancy projects, etc., can solve the problems of not being able to effectively provide cleaning at the bottom of the trash rack, and achieve compact structure, low cost, and high cleaning efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

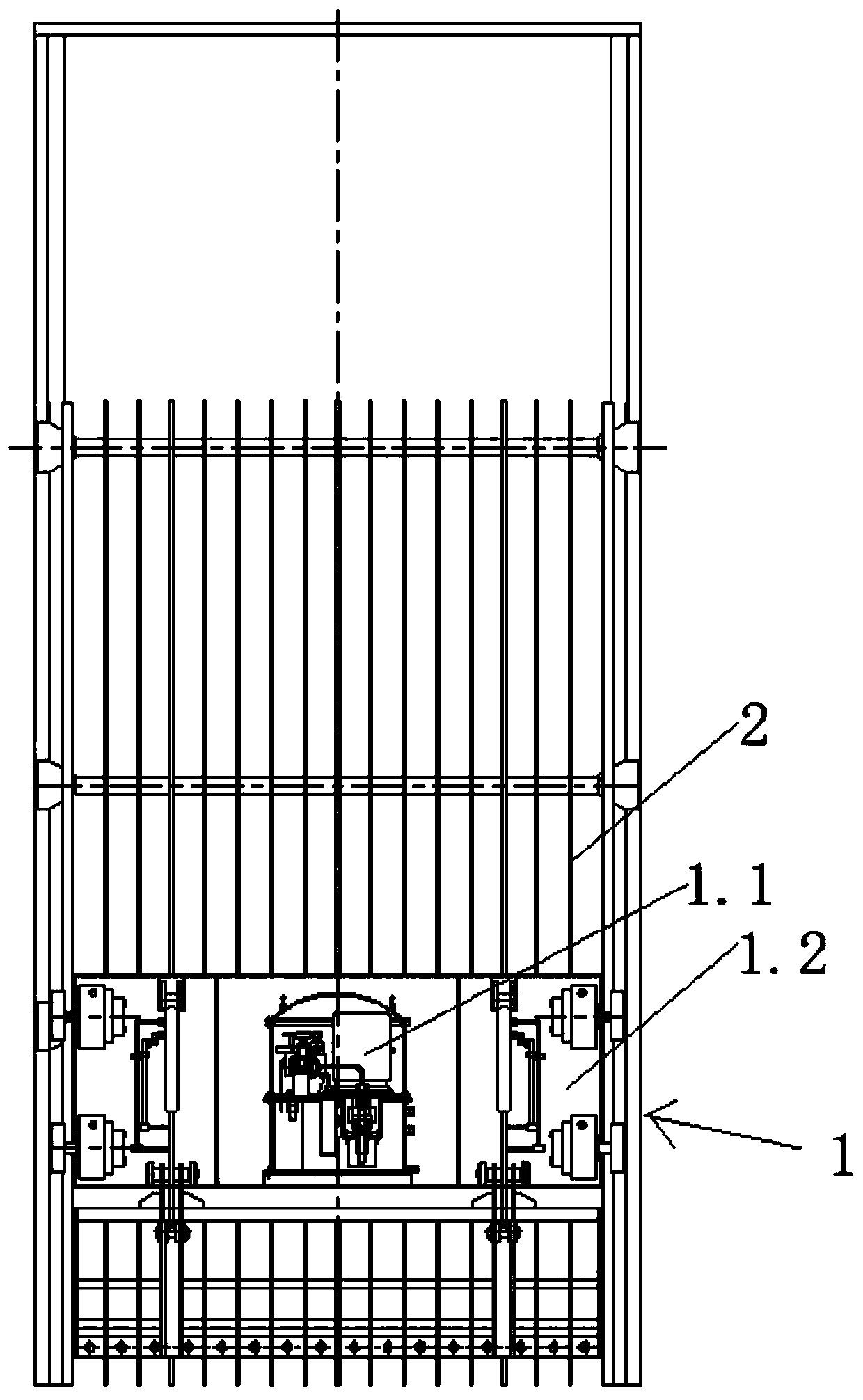

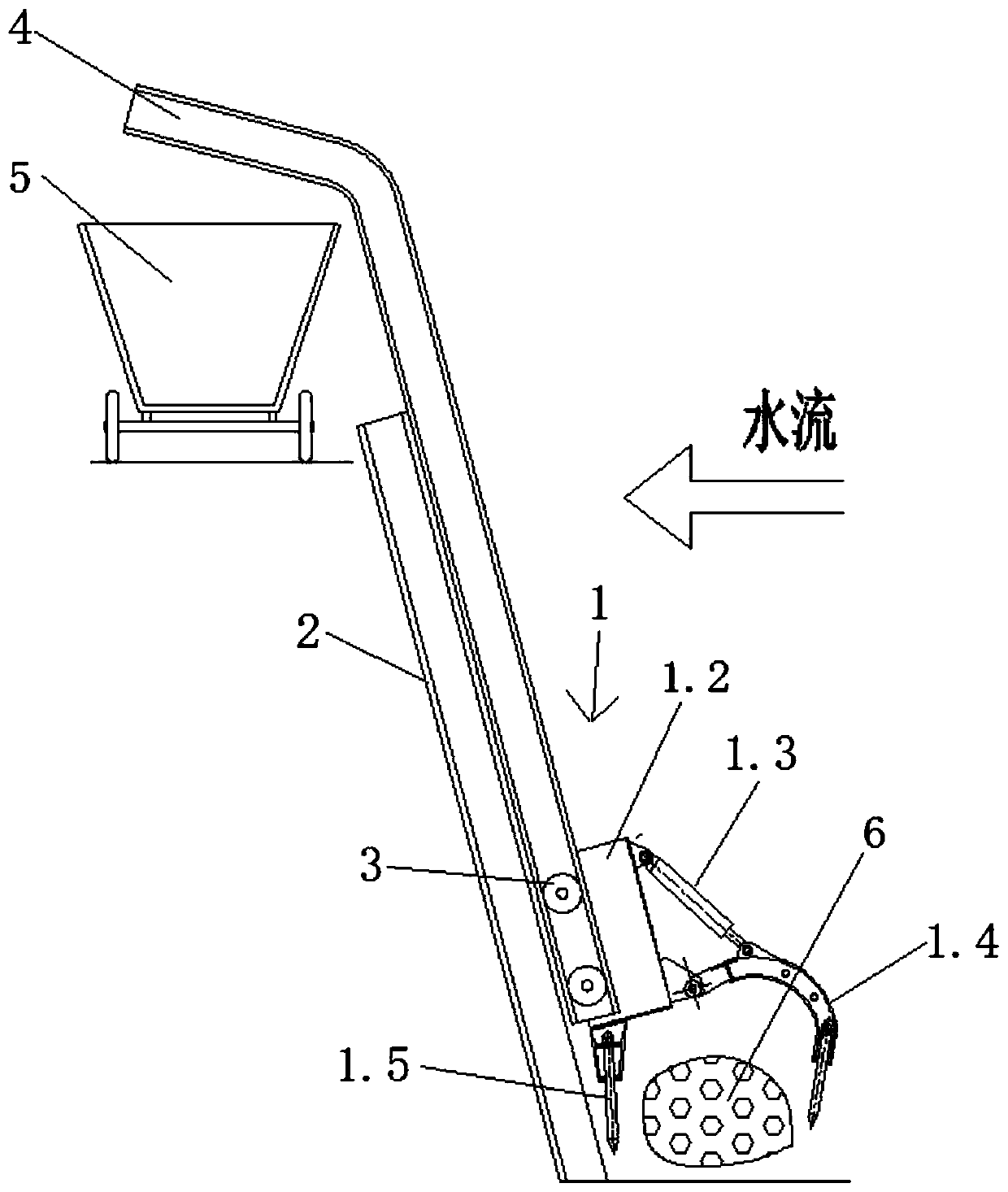

[0026] see Figure 1 to Figure 2 A trash rack with a trash rack as shown includes a trash rack 2 and a trash rack device 1 arranged on the trash rack 2, such as Figure 5 to Figure 6 The cleaning grab device 1 shown includes a cleaning grab 1.2 arranged on the trash rack 2. The bottom of the cleaning grab 1.2 is provided with shovel teeth 1.5, and the cleaning grab 1.2 is also provided with rotating teeth 1.4. And the rotating drive device that drives rotary gear 1.4 to rotate. The rotary driving device in this embodiment includes a hydraulic cylinder 1.3 connected to the rotary gear 1.4 and a hydraulic system 1.1 for driving the hydraulic cylinder 1.3 to work.

[0027] The rotating gear 1.4 has an arc-shaped structure as a whole. One end of the rotating gear 1.4 is hinged on the cleaning bucket 1.2. The other end of the rotating gear 1.4 is used to grab the dirt 6 at the bottom of the trash rack. One end of the hydraulic cylinder 1.3 is hinged on the cleaning bucket. On the...

Embodiment 2

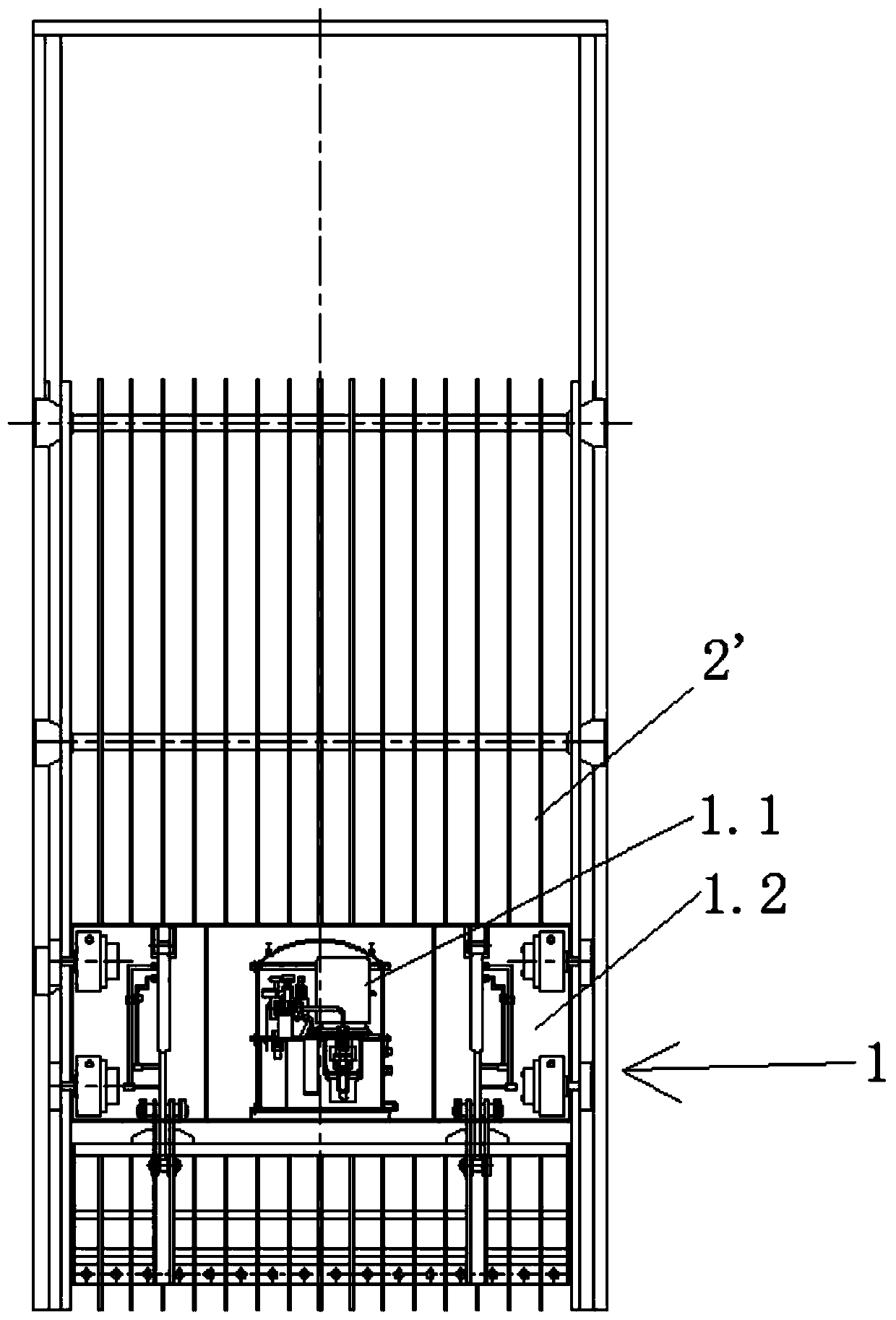

[0033] see Figure 3 to Figure 4 Shown a kind of trash rack with cleaning bucket, including trash rack 2 ' and being arranged on trash rack 2 ', the cleaning grab bucket set 1, as Figure 5 to Figure 6 The cleaning grab device 1 shown includes a cleaning grab 1.2 that is arranged up and down on the trash rack 2'. The bottom of the cleaning grab 1.2 is provided with shovel teeth 1.5, and the cleaning grab 1.2 is also provided with rotating teeth. 1.4 and the rotary driving device that drives rotary gear 1.4 to rotate. The rotary driving device in this embodiment includes a hydraulic cylinder 1.3 connected to the rotary gear 1.4 and a hydraulic system 1.1 for driving the hydraulic cylinder 1.3 to work.

[0034] The rotating gear 1.4 has an arc-shaped structure as a whole. One end of the rotating gear 1.4 is hinged on the cleaning bucket 1.2. The other end of the rotating gear 1.4 is used to grab the dirt 6 at the bottom of the trash rack. One end of the hydraulic cylinder 1.3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com