Acoustic attenuation panel for aircraft

An aircraft and panel technology, applied in the field of aircraft, can solve the problems of adding units, shortcomings of weight and size, and increasing structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

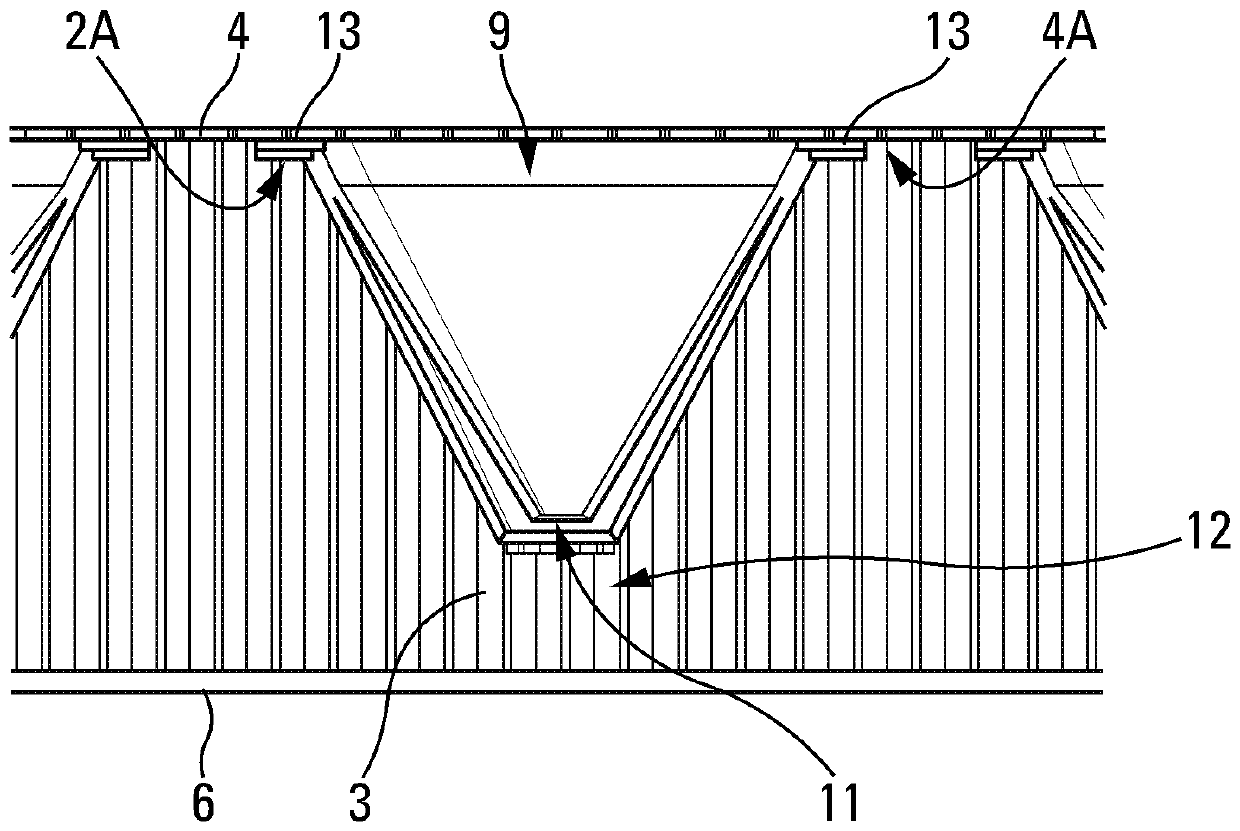

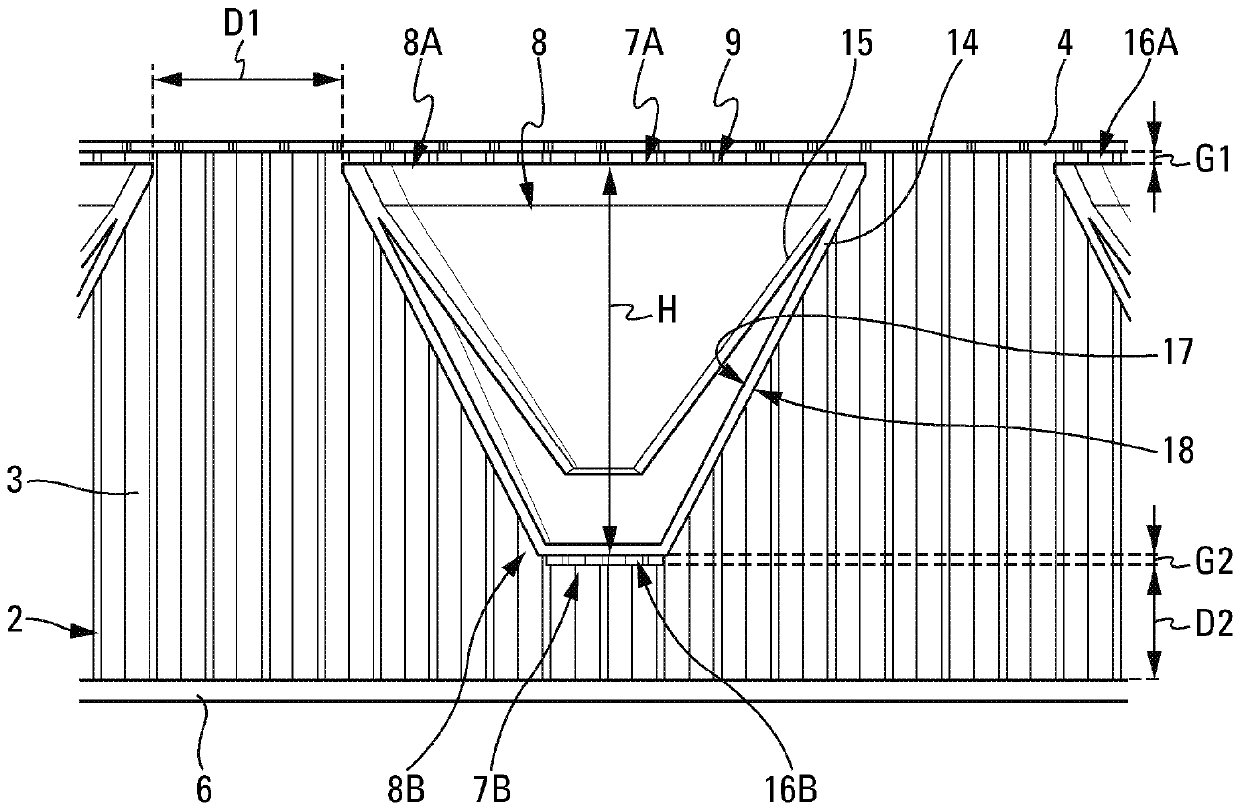

[0041] exist figure 1 presented schematically in and makes it possible to show that the acoustic panel 1 (or acoustically attenuating panel) of the invention is intended to make it possible to reduce (or attenuate) the noise on an aircraft (not represented), in particular a transport aircraft, by absorbing it. noise. In a preferred embodiment, this acoustic panel 1 is intended to make it possible to reduce the noise on the cabin (not represented) of the aircraft's engine.

[0042] Typically, the acoustic panel 1 includes such as figure 1 and figure 2 Presented in exploded view in:

[0043] - a panel 2 made of sound-absorbing material 3, that is to say capable of absorbing noise to attenuate it;

[0044] - a so-called resistive skin 4 which is sound-permeable, that is to say for example provided with a plurality of perforations (or holes, voids, openings) 5 passing right through said resistive skin 4, said perforations 5 being in particular Depend on figure 1 and 2 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com