Magnetic suspension shock absorber

A shock absorber, magnetic suspension technology, applied in the direction of spring/shock absorber, magnetic spring, spring, etc., can solve the problems of high cost, shock absorber failure, limited application of spring shock absorber, etc. The effect of low precision requirements and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

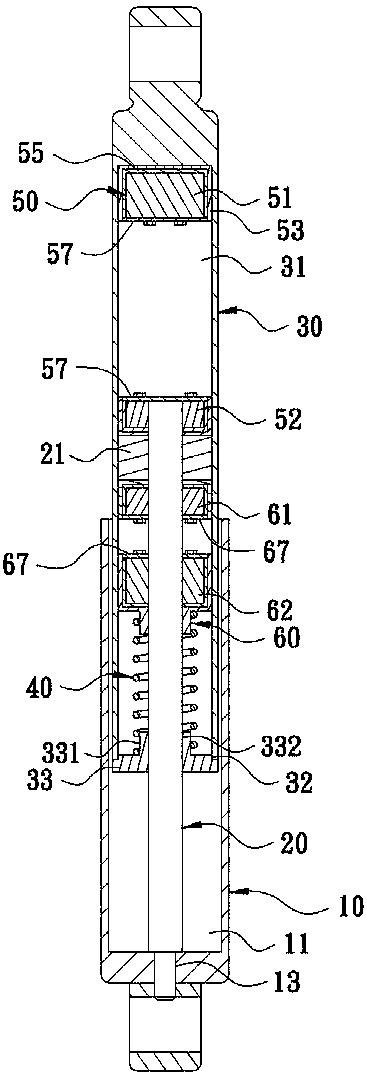

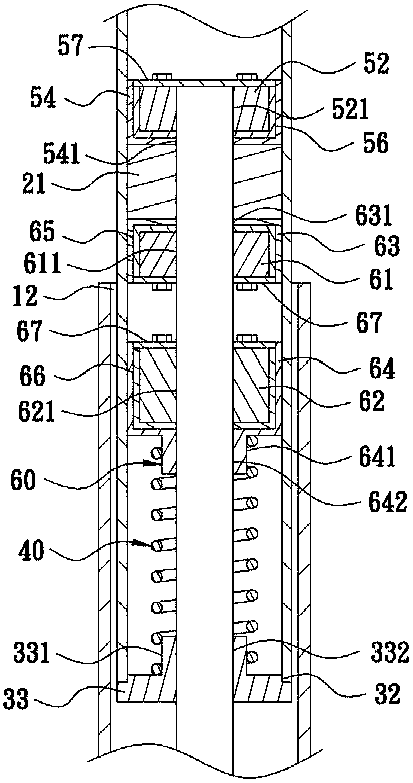

[0020] Please see first Figure 1 to Figure 3 As shown, it discloses a magnetic suspension shock absorber, which includes:

[0021] An outer casing 10, which is in the shape of a hollow cylinder, has a container 11 in the outer casing 10, and one end of the outer casing 10 is provided with an opening 12, and the opening 12 communicates with the container 11, and the outer casing 10 The other end is provided with a through hole 13 .

[0022] One end of a shaft 20 is disposed in the through hole 13 of the outer cylinder 10 , and the other end of the shaft 20 is disposed in the cavity 11 of the outer cylinder 10 , passes through the opening 12 , and is provided with a piston 21 .

[0023] An inner sleeve cylinder 30, which is arranged on the shaft rod 20, and is slidably arranged in the housing groove 11 of the outer sleeve cylinder 10, and the inner sleeve cylinder 30 is hollow and long cylindrical corresponding to the outer sleeve cylinder 10, the inner sleeve cylinder 30 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com