Micro-deformation self-adaptive inner ring wall structure

An adaptive, micro-deformation technology, applied in the direction of furnace, furnace lining, lighting and heating equipment, etc., can solve the problems of aggravating the wall, not solving the stability problem of the inner ring wall from the principle, and not having a fixing function, etc., to achieve The effect of absorbing thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

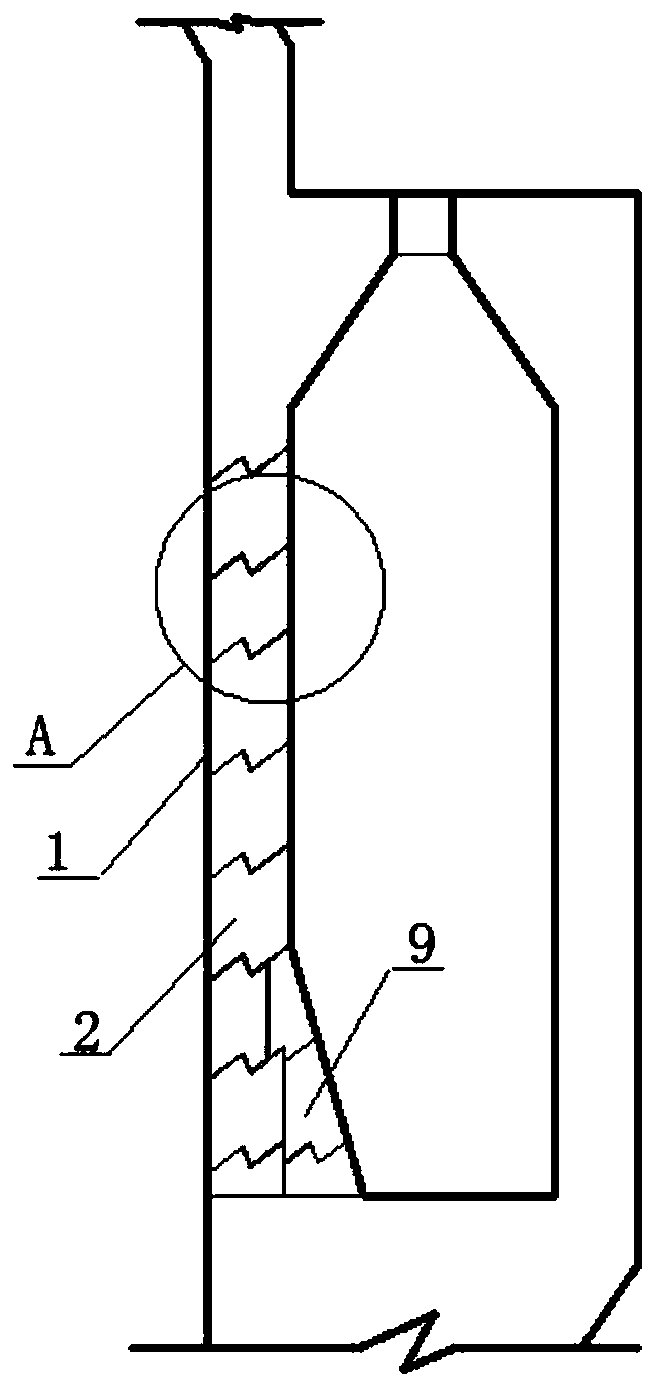

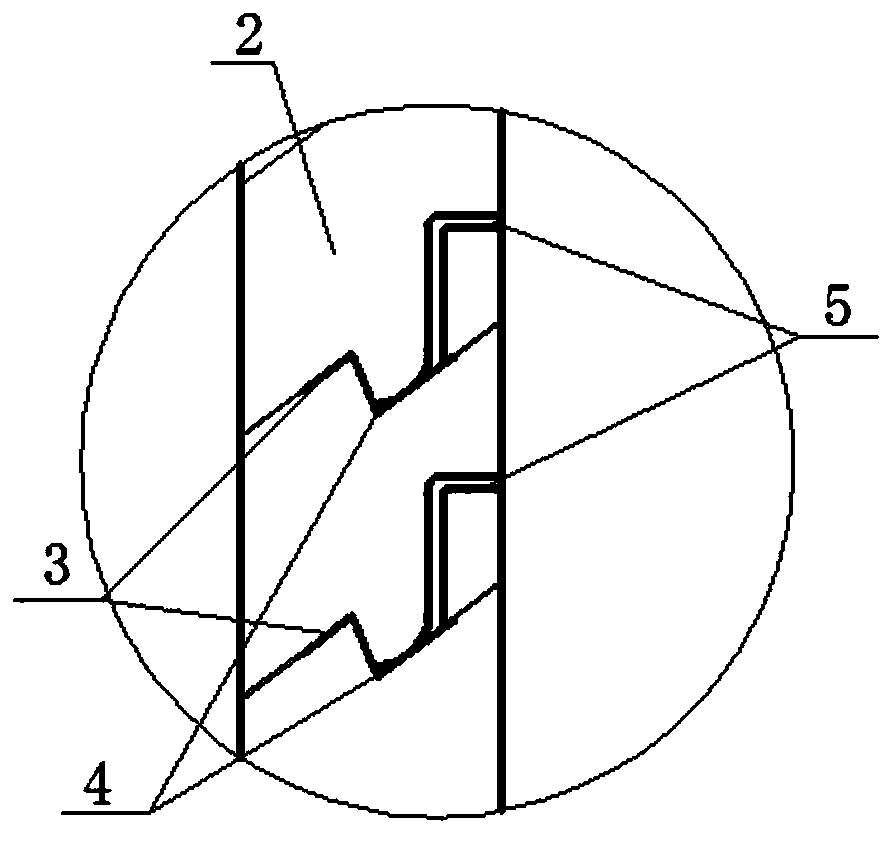

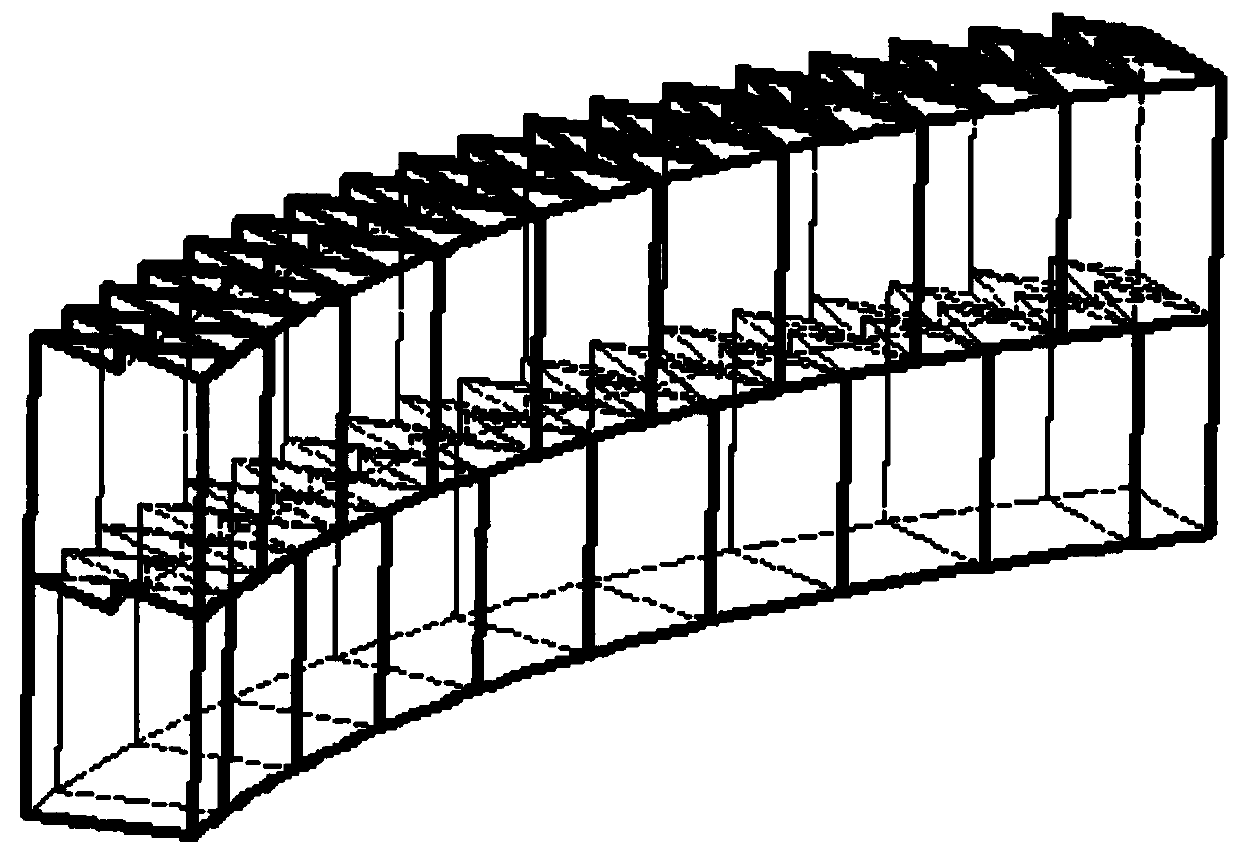

[0025] like figure 1 , figure 2 As shown, a micro-deformation self-adaptive inner ring wall structure of the present invention includes an inner ring wall 1 located in the annular air duct area of a gas-solid heat exchange shaft furnace; the inner ring wall 1 is composed of Multi-layer refractory blocks 2 are built by masonry; such as image 3 As shown, the upper surface and the lower surface of the refractory block 2 are fold-line surfaces inclined outward and upward, and the two adjacent layers of refractory blocks 2 are connected through the snap-line surface and can be connected along the gas-solid heat exchange formula. The radial and circumferential sliding of the shaft furnace; grouting holes 5 are set on the refractory blocks 2 outside the inner ring wall 1, and the fold lines of the adjacent two layers of refractory blocks 2 are comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com