In-can coating film integrity tester

An integrity and measuring instrument technology, applied in the field of coating film integrity measuring instrument in the tank, can solve the problems of poor operability, poor measurement accuracy, narrow application range, etc., to achieve the effect of reliable test results and increased accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

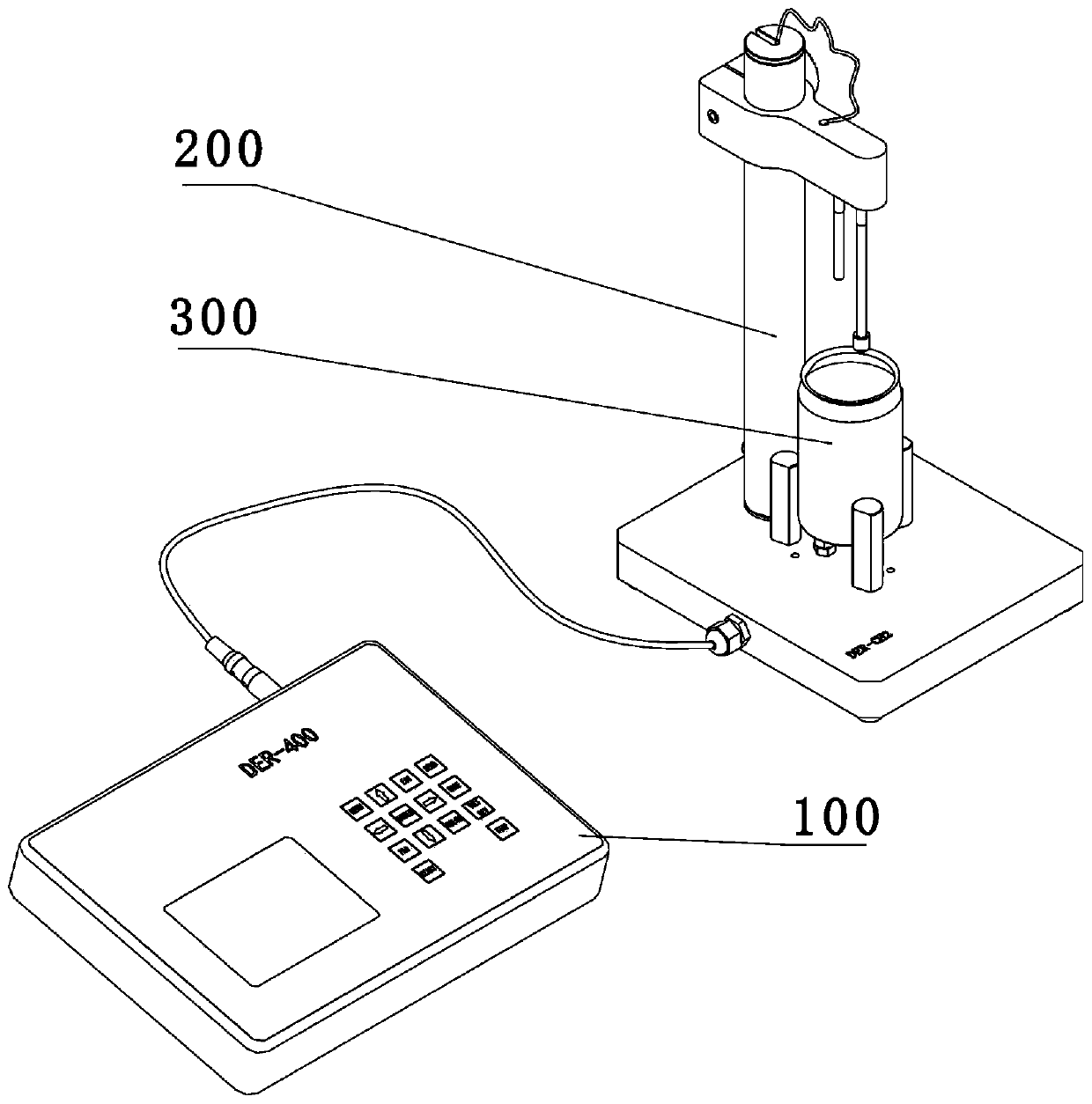

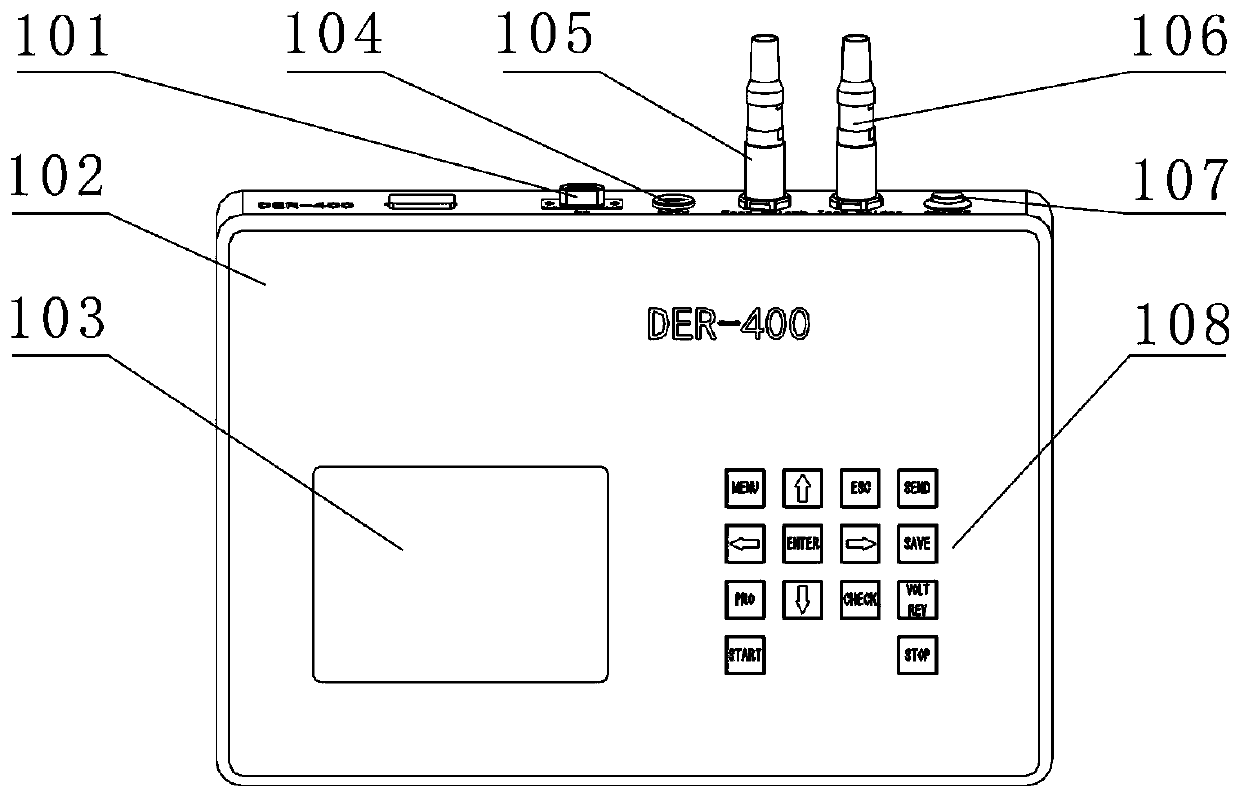

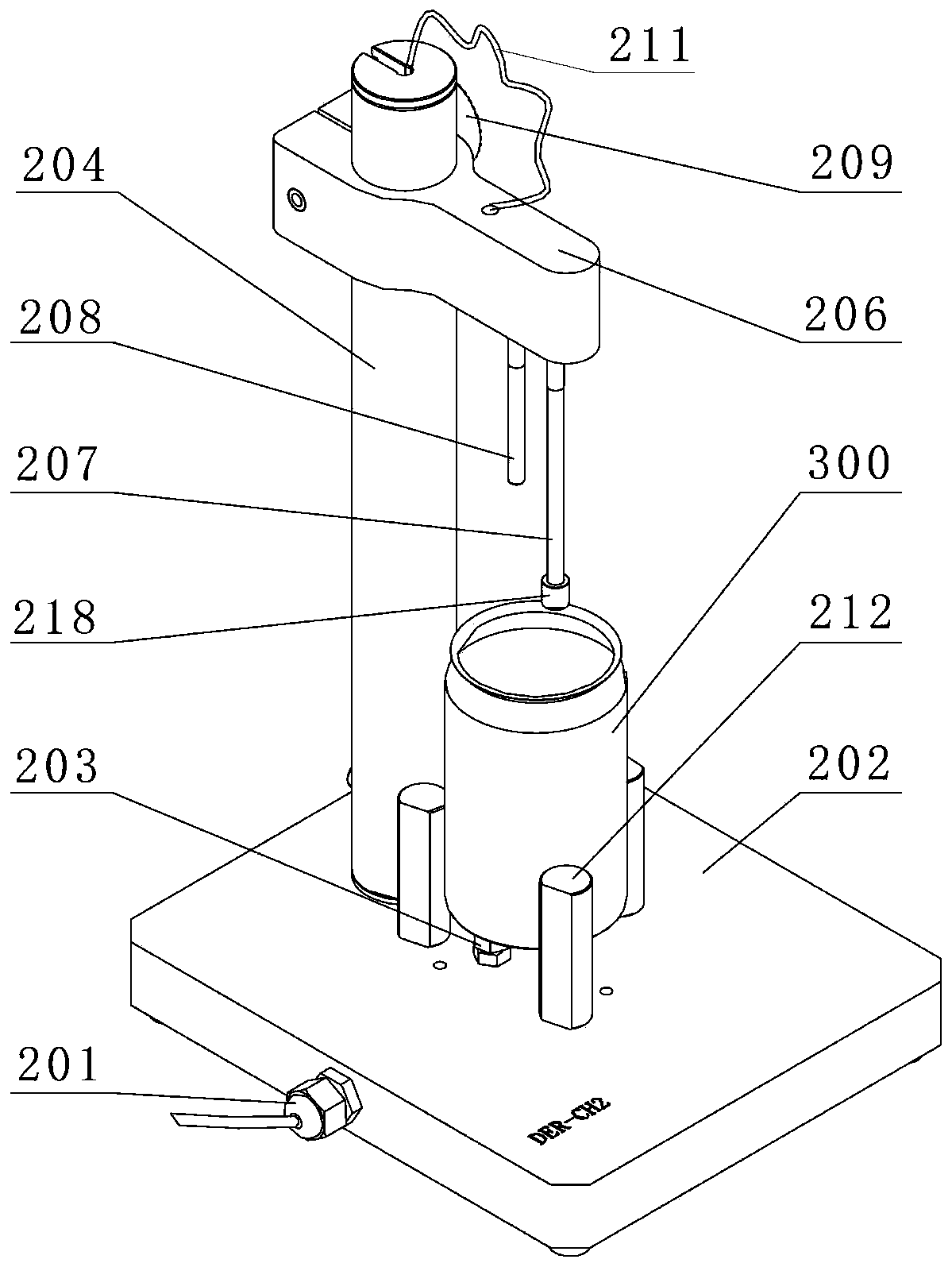

[0057] Such as figure 1 As shown, the embodiment of the present invention discloses a tank coating integrity tester, including a host display controller 100, a tank body support 200 electrically connected to the host display controller 100, such as figure 2 As shown, the host display controller 100 includes a communication connector 101, a host box 102, a display screen 103, a charging connector 104, a foot switch line 105, a fixture connection line 106, a power supply 107, and a keypad 108. The fixture connection line 106 is connected with the fixture connection line 201 on the can body support 200 to realize the electrical connection between the host display controller 100 and the corresponding structure on the can body support 200 .

[0058] The tank body support 200 in this embodiment is specially applied to the sample tank 300 of the two-piece tank type.

[0059] Such as Figure 3-5 As shown, the can body support 200 in this embodiment includes a bottom plate 202, and ...

Embodiment 2

[0070] The tank body support 200 in this embodiment is specially applied to the sample tank 300 of the three-piece tank type.

[0071] The structure of the can body bracket 200 in this embodiment is basically the same as that applicable to two-piece cans in Embodiment 1, the difference is that, as Figure 6-7 As shown, the bottom scraping needles 203 in this embodiment are arranged in three characters, and the bottom scraping needles 203 are electrically connected to the host display controller 100 through the fixture connection line 201 to detect whether the sample tank is in contact with the bottom scraping needles 203 Scrape through the outer coating. Two auxiliary support strips 213 are added to the sides of the bottom scraping needle 203, and the height of the auxiliary support strips 213 is lower than that of the bottom scraping needle 203 (preferably 1mm lower), which can properly support the sample tank and reduce the tilting of the sample tank.

[0072]In this embodi...

Embodiment 3

[0075] The tank body support 200 in this embodiment is specially applied to the spray sample tank 300 .

[0076] The structure of the can body support 200 in this embodiment is basically the same as that applicable to two-piece cans in Embodiment 1, the difference is that the electrode needles in this embodiment are further designed as a telescopic structure, that is, the telescopic length can be quickly Adjustment, the electrode needle can also be pulled out for replacement, so as to adapt to the height of different sample tanks in a wider range. Additionally, if Figure 8 As shown, the bottom scraping needles 203 in this embodiment are arranged in three characters, and the bottom scraping needles 203 are electrically connected to the host display controller 100 through the fixture connection line 201 to detect whether the sample tank is in contact with the bottom scraping needles 203 Scrape through the outer coating. Two auxiliary support strips 213 are added to the sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com