Circuit control type oven

A circuit control and oven technology, applied in the field of ovens, can solve problems such as high cost and complex structure, and achieve the effects of low cost, simple circuit structure, and preventing food from being scorched and burnt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

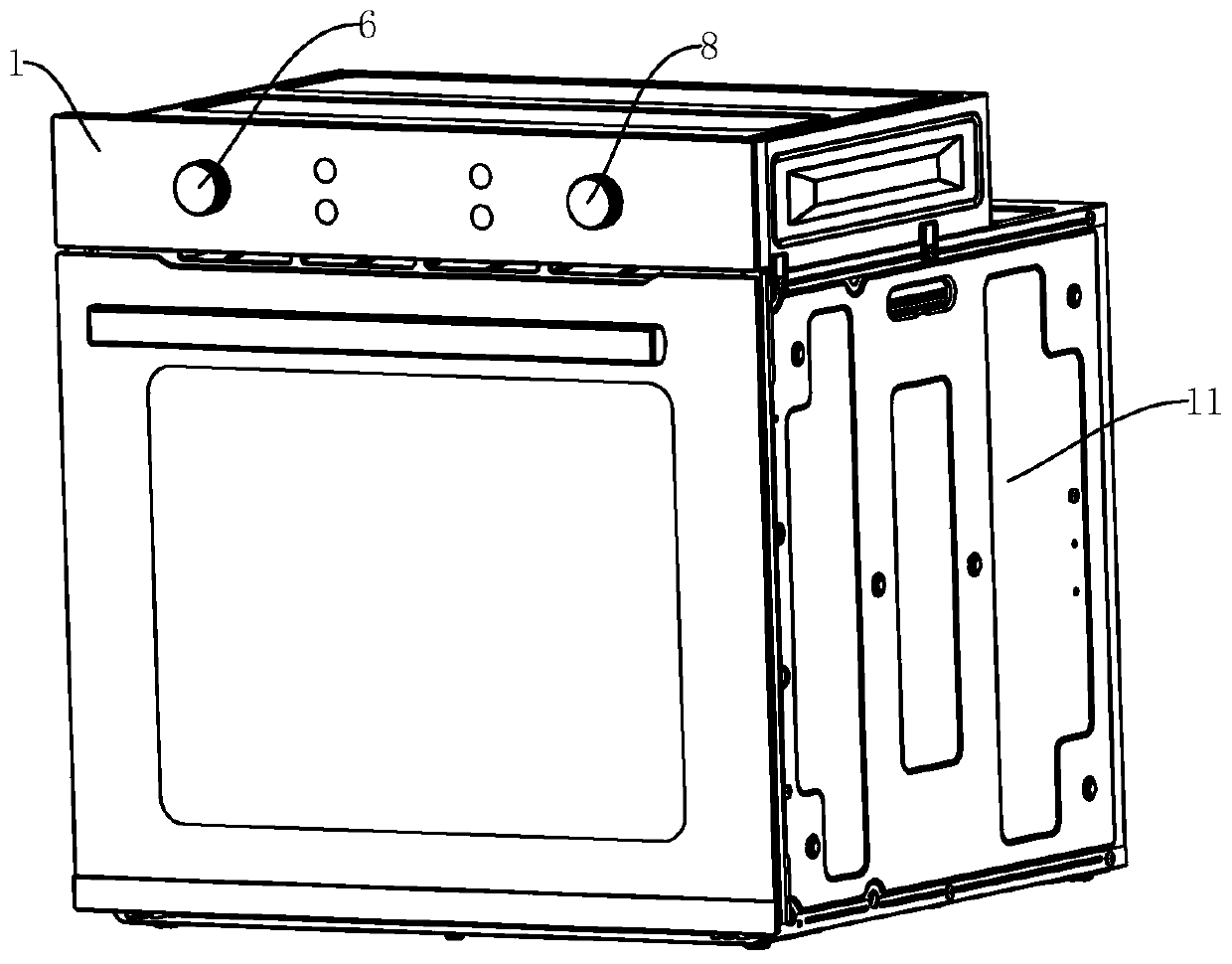

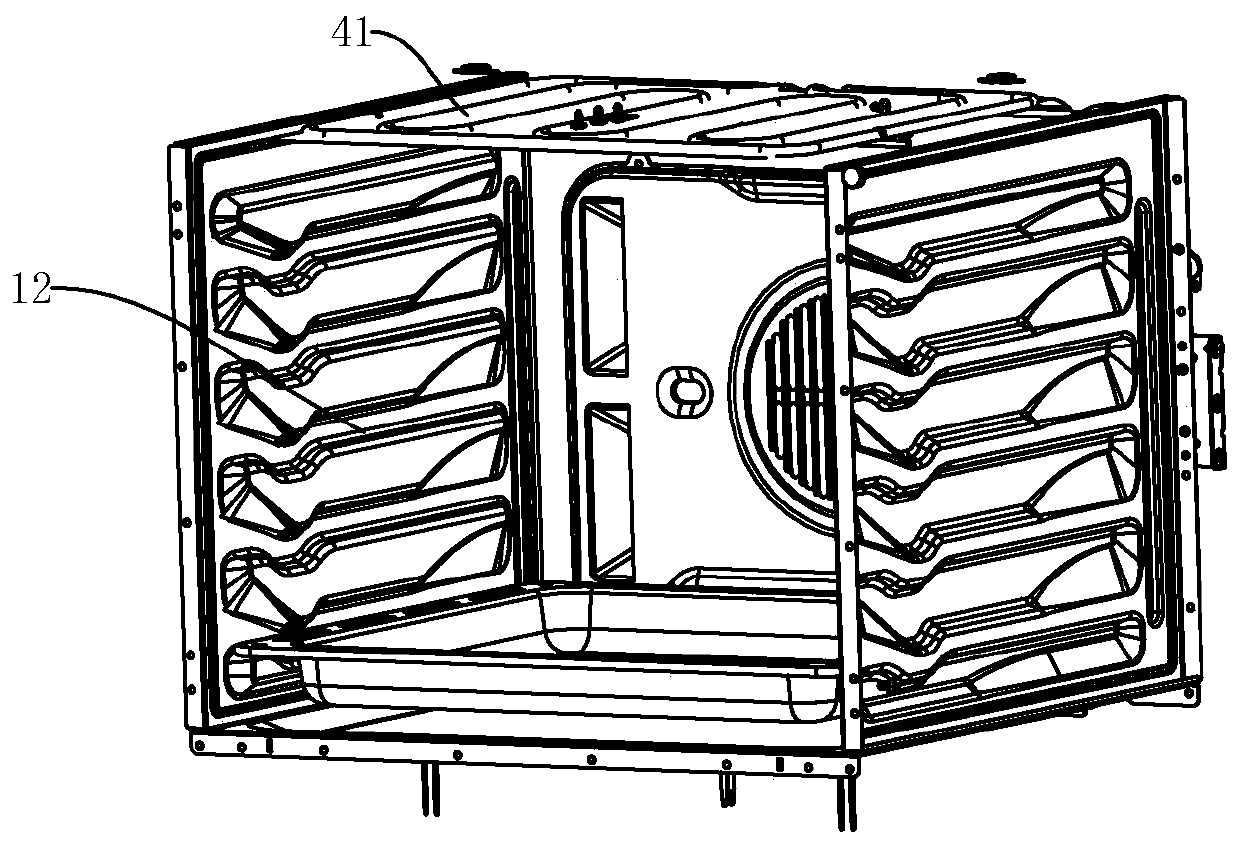

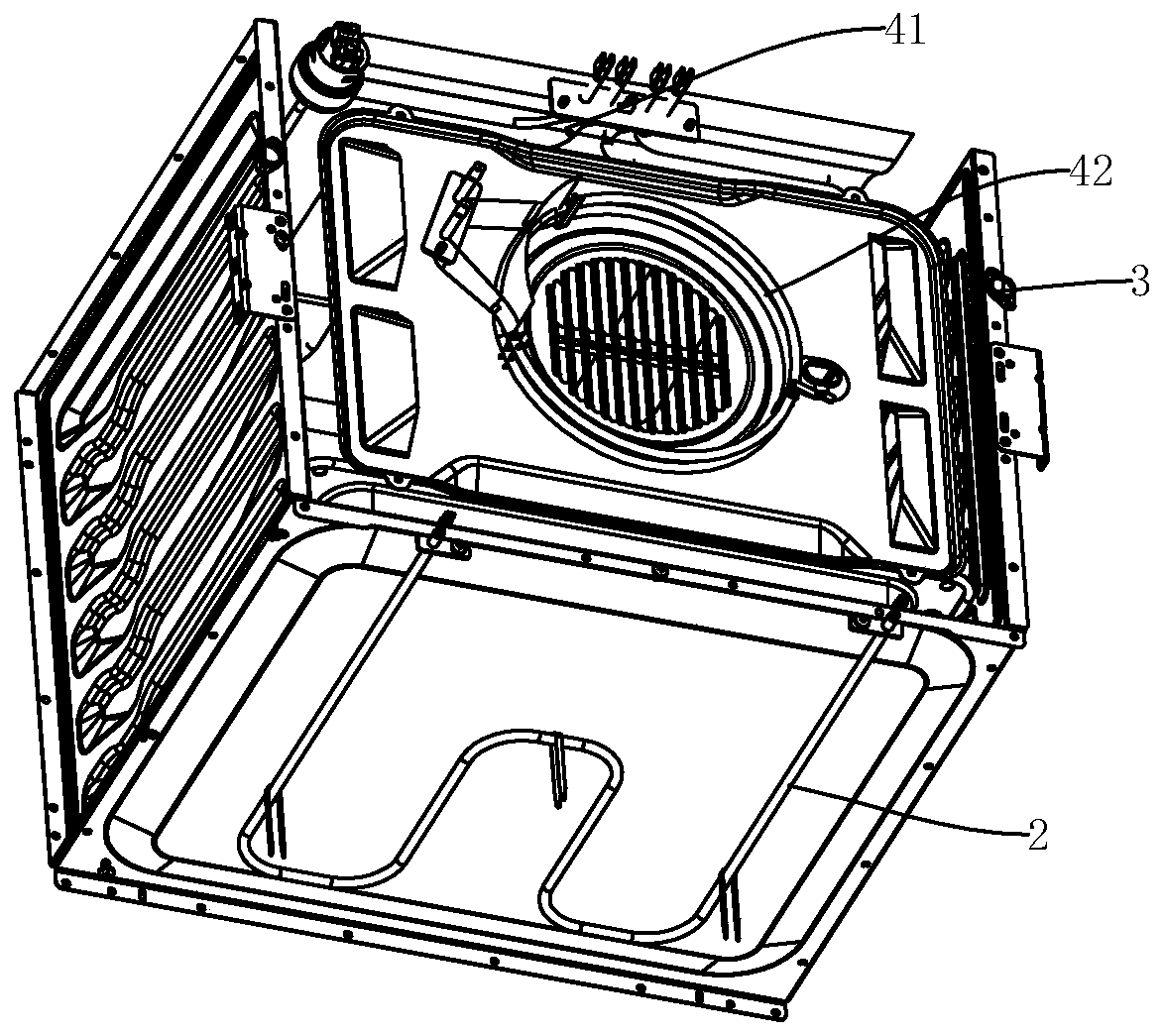

[0029] Such as Figure 1-Figure 6 As shown, a circuit-controlled oven includes an oven body 1;

[0030] The first heating component 2 is arranged at the bottom of the oven body 1;

[0031] The second heating component 4 is arranged on the top or side of the oven body 1;

[0032] The first power supply branch and the second power supply branch are connected in parallel, the first heating component 2 is connected in series in the first power supply branch, and the second heating component 4 is connected in series in the second power supply branch;

[0033] The first temperature control switch assembly 3 is arranged on the oven body 1 to detect the heating temperature, the first temperature control switch assembly 3 is connected in series in the first power supply branch, and the first temperature control switch assembly 3 is provided with a first temperature threshold, When the heating temperature exceeds the first temperature threshold, the first temperature control switch assembly 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com