Balanced vibration system

A vibration system and balance technology, applied in the direction of diaphragm fixation/tightening, sensors, electrical components, etc., can solve the problems of unilateral vibration distortion, large energy loss, low signal conversion efficiency, etc., to eliminate distortion and reduce power consumption. The effect of high power consumption and signal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

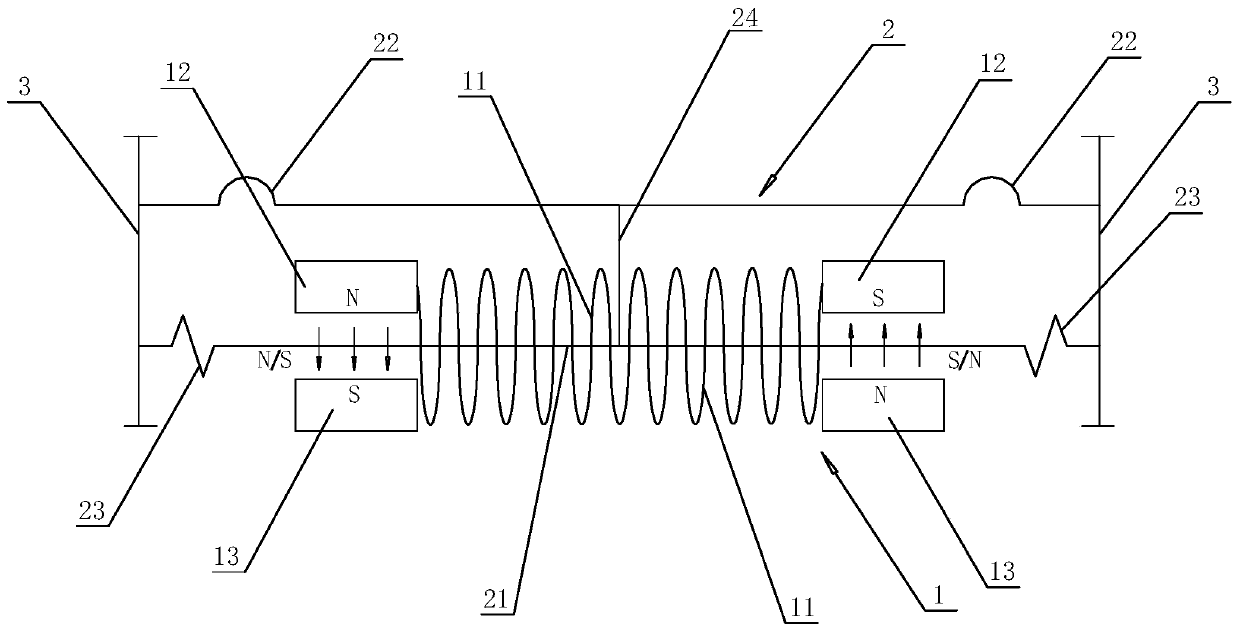

[0027] Embodiment 1, combining figure 1 , a balanced vibration system, including a magnetic circuit unit 1, a vibration unit 2 and a housing 3, the magnetic circuit unit 1 and the vibration unit 2 are located inside the housing 3, the magnetic circuit unit 1 is fixed on the housing 3, and the vibration The unit 2 is elastically connected with the casing 3, and the vibration unit 2 vibrates with the change of the magnetic field of the magnetic circuit unit 1 to realize vibration. The magnetic circuit unit 1 includes a set of magnetic circuit coils 11 and two magnet groups. The two magnet groups are respectively located at the left and right ends of the set of magnetic circuit coils 11 in the axial direction. Fixedly connected, the two terminals of the magnetic circuit coil 11 are fixed on the casing 3, and can be electrically connected to the signal source through wires. According to the law of electromagnetic conversion, the magnetic circuit coil 11 will generate an induced m...

Embodiment 2

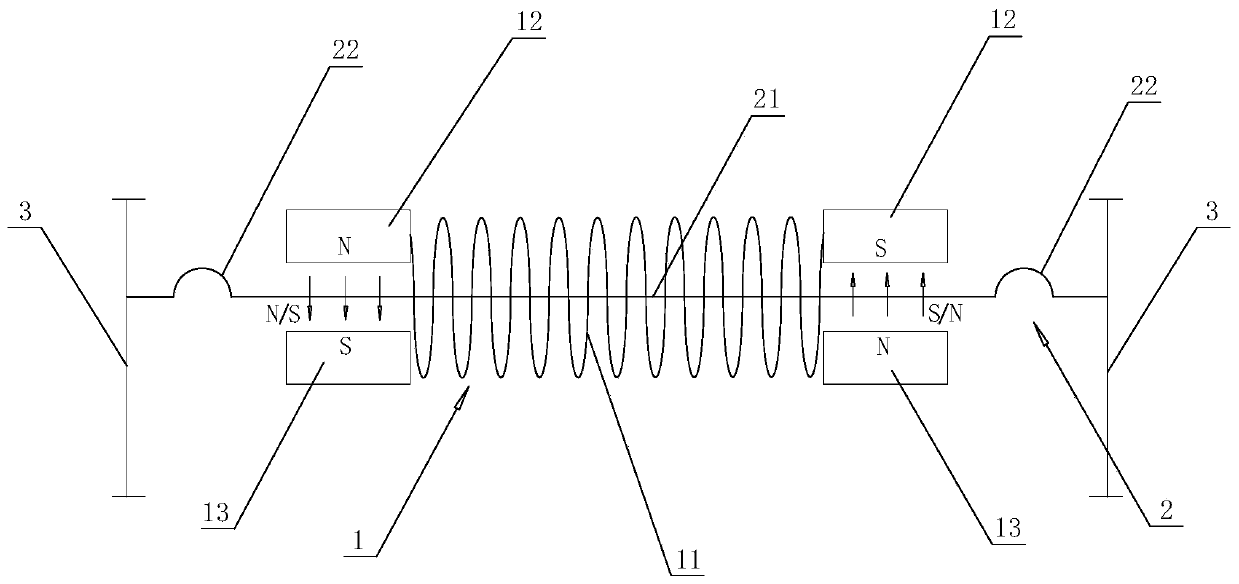

[0033] Example 2, combined with figure 2 , a balanced vibration system, including a magnetic circuit unit 1, a vibration unit 2 and a housing 3, the magnetic circuit unit 1 and the vibration unit 2 are located inside the housing 3, the magnetic circuit unit 1 is fixed on the housing 3, and the vibration The unit 2 is elastically connected with the casing 3, and the vibration unit 2 vibrates with the change of the magnetic field of the magnetic circuit unit 1 to realize vibration. The magnetic circuit unit 1 includes a magnetic circuit coil 11 and two magnet groups, and the two magnet groups are respectively located at the left and right ends of the magnetic circuit coil 11 axial direction, and the two ends of the magnetic circuit coil 11 are respectively fixed with the magnet groups located at the left and right ends of the magnetic circuit coil. The two terminals of the magnetic circuit coil 11 are fixed on the casing 3 and can be electrically connected to the signal source ...

Embodiment 3

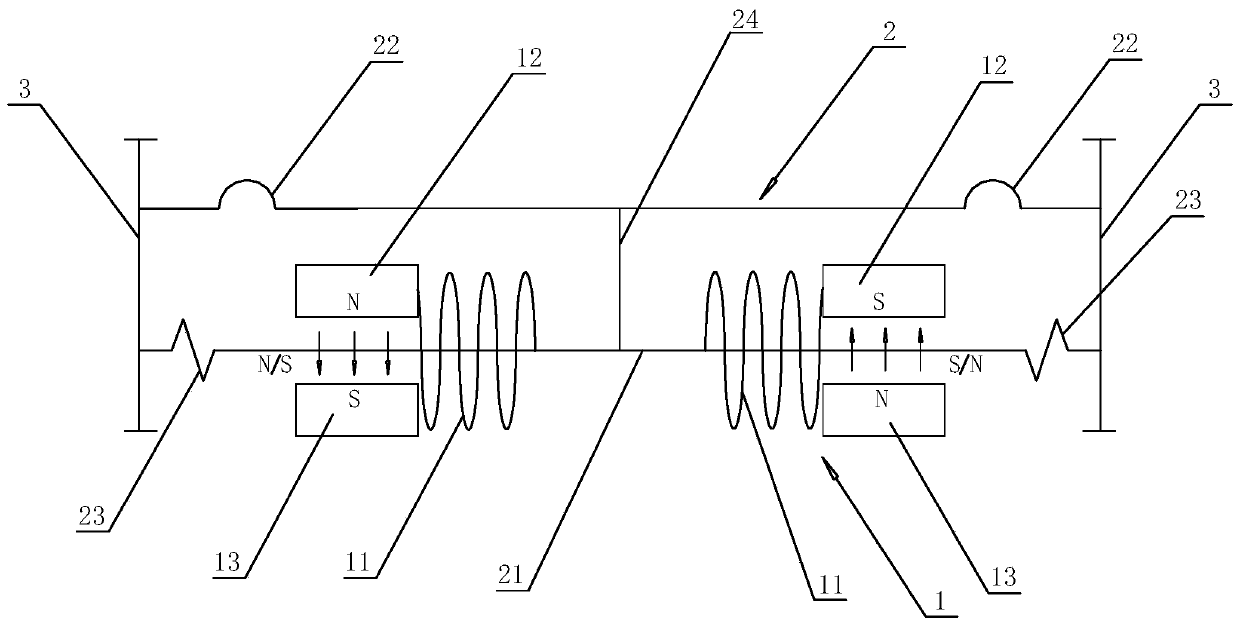

[0037] Embodiment 3, combining image 3 and Figure 4 , the principle of embodiment 3 is the same as that of embodiment 1, and the structure is basically the same. The difference between embodiment 3 and embodiment 1 is that the magnetic circuit unit 1 of embodiment 3 includes two sets of magnetic circuit coils 11, and two sets of magnetic circuit coils. The coils 11 are respectively located on opposite sides of the two magnet groups, that is, two sets of magnetic circuit coils 11 are located between the two magnet groups, and the opposite ends of the two sets of magnetic circuit coils 11 are fixedly connected to the corresponding magnet groups (such as image 3 shown). Simultaneously, two groups of magnetic circuit coils 11 can also be positioned at opposite sides of two magnet groups respectively, namely two groups of magnetic circuit coils 11 are positioned at the outside of two magnet groups, and the opposite end of two groups of magnetic circuit coils 11 is fixed with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com