Frequency distortion correction-type digital strain-type torque sensor based on signal conversion

A torque sensor and frequency distortion technology, applied in the field of sensors, can solve the problems of analog signal distortion and low signal conversion efficiency, and achieve the effects of convenient calibration, high signal conversion efficiency, improved anti-interference ability and transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

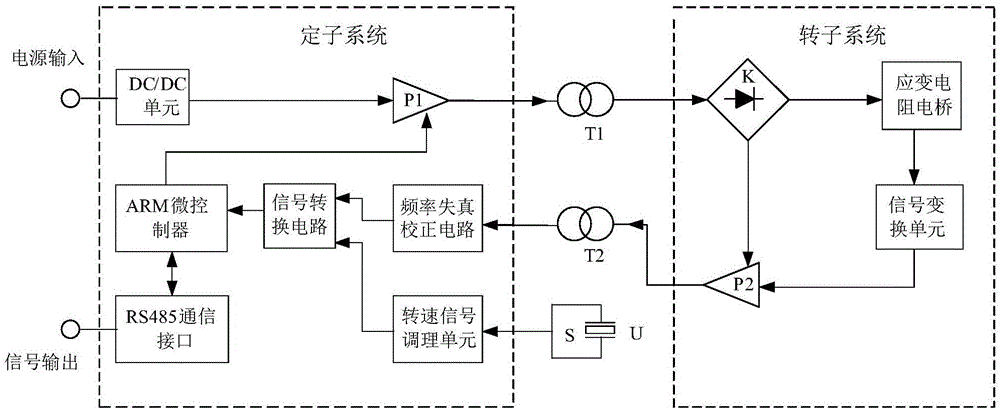

[0023] Such as figure 1 As shown, the digital strain gauge torque sensor based on the frequency distortion correction circuit of the present invention is composed of a gear plate U, a photoelectric switch S, a stator system, a resolver T1, a resolver T2, and a rotor system. The toothed disk U is fixed on the rotor of the sensor, and one end of the photoelectric switch S is connected with the toothed disk U, and the other end is connected with the stator system. At the same time, the primary side of the resolver T1 is connected to the stator system, and its secondary side is connected to the rotor system. The primary side of the resolver T2 is connected to the rotor system, and its secondary side is connected to the stator system. The photoelectric switch S cooperates with the gear plate U to detect the speed of the rotor rotation, and outputs a corresponding frequency pulse signal to the stator system.

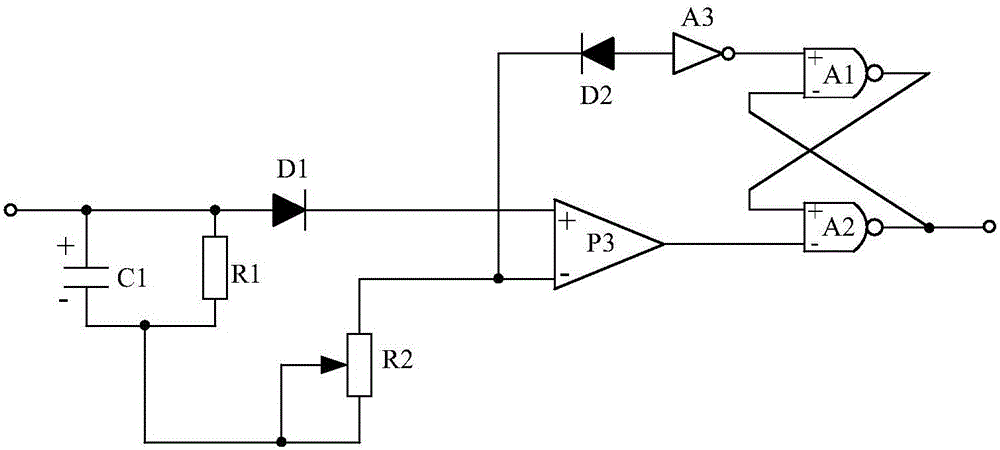

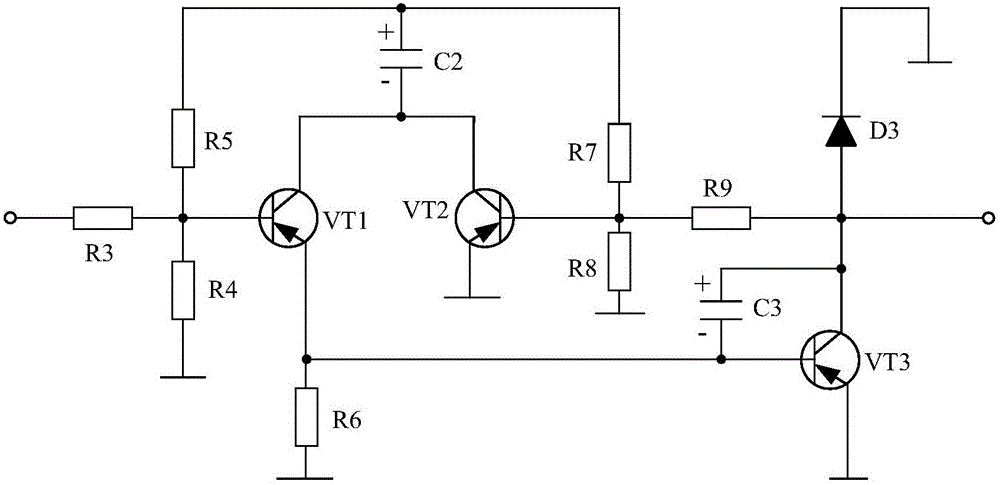

[0024] In order to better process the frequency pulse signal sent by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com