One-piece compressor controller of new energy automobile

A new energy vehicle, integrated technology, applied in liquid variable capacity machinery, pump control, machine/engine and other directions, can solve problems such as poor heat dissipation of electric compressor controller, uncommon interface, etc., to facilitate traceability, tracking and solving Insulation and heat dissipation problems, the effect of improving stability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

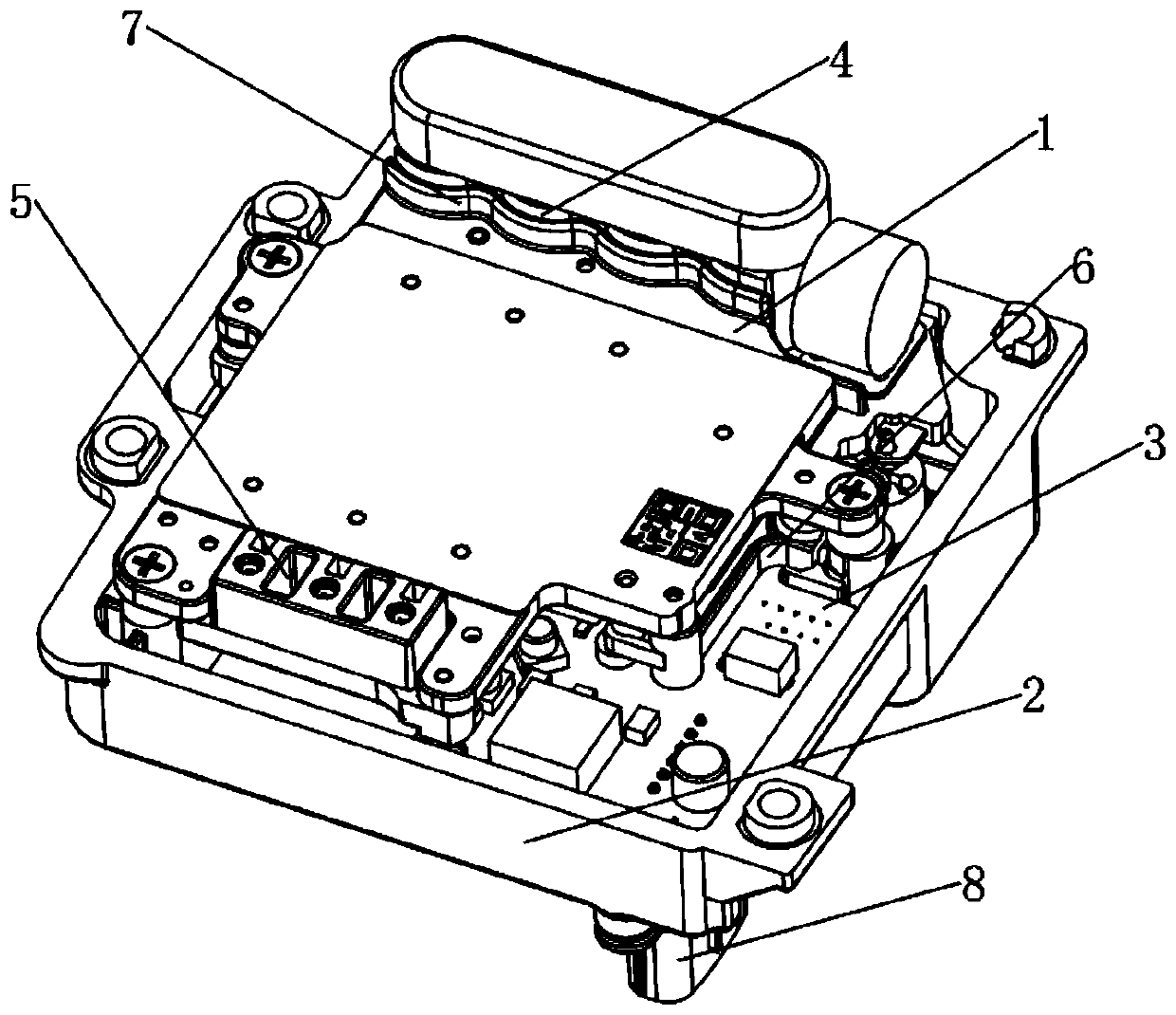

[0032] Depend on figure 1 As shown, an integrated compressor controller for a new energy vehicle includes a heat dissipation base plate 1, an upper cover 2, a printed board 3, electronic components 4, three-phase terminals 5 and a copper strip module 6, a heat dissipation base plate 1, an upper cover 2. The printed board 3, the electronic components 4, the three-phase terminal 5 and the copper bar module 6 are fixedly connected;

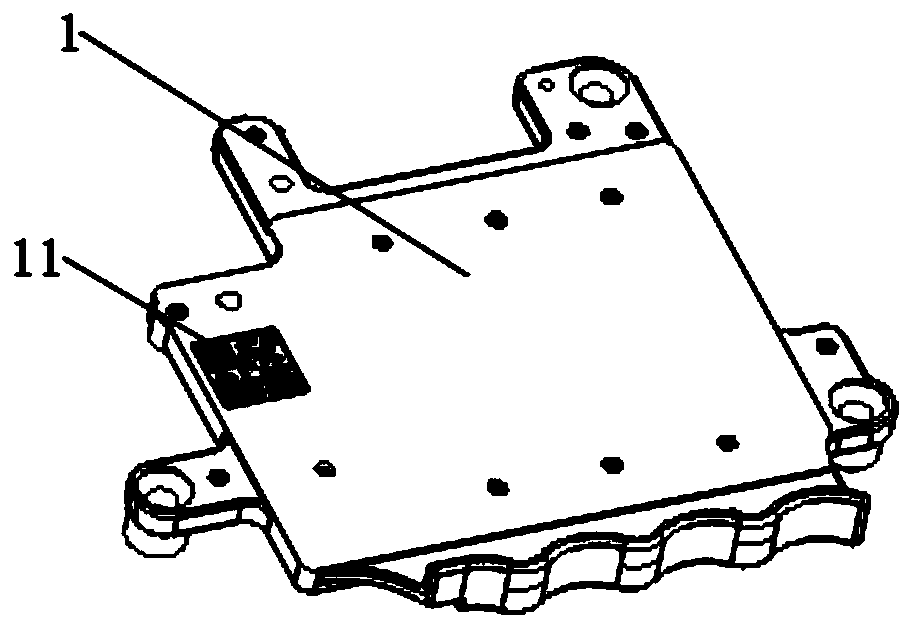

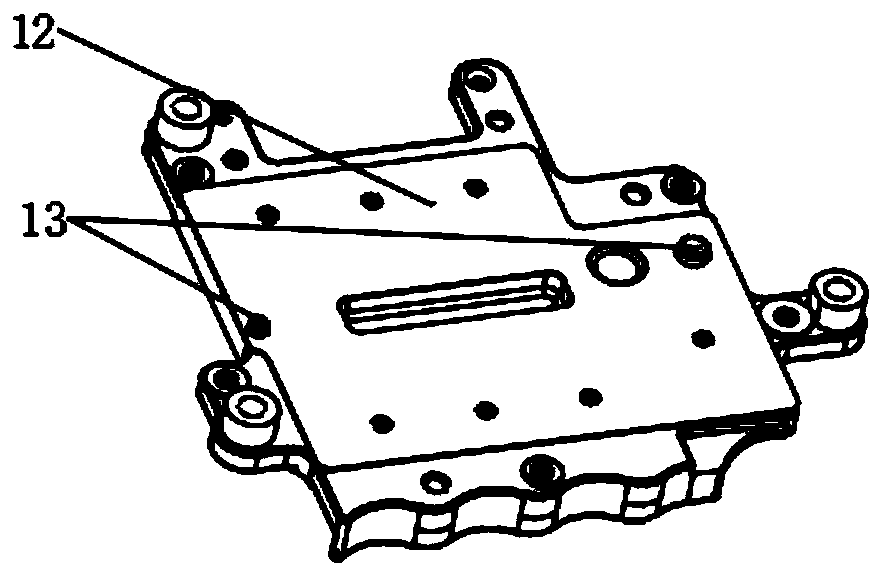

[0033] Such as figure 2 and image 3 As shown, the heat dissipation bottom plate 1 is the shape of the compressor controller bottom plate in the prior art, and a two-dimensional code 11 is provided on the heat dissipation bottom plate 1 by laser marking, which is used for tracing product information in the later stage. Another part of the heat dissipation bottom plate 1 One side is provided with a thermally conductive insulating cloth 12, and the thermally conductive insulating cloth 12 is positioned and installed through the positioning column 13...

Embodiment 2

[0040] Depend on figure 1 As shown, an integrated compressor controller for a new energy vehicle includes a heat dissipation base plate 1, an upper cover 2, a printed board 3, electronic components 4, three-phase terminals 5 and a copper strip module 6, a heat dissipation base plate 1, an upper cover 2. The printed board 3, the electronic components 4, the three-phase terminal 5 and the copper bar module 6 are fixedly connected;

[0041] In this embodiment, the barcode 11 is printed on the heat dissipation bottom plate 1 by means of laser marking, and the others are the same as in the first embodiment.

[0042] In summary, the working principle of the present invention is:

[0043] Compared with the conductive strips on the printed circuit board, the copper strip module 6 can withstand a larger current, which solves the problem that ordinary circuit boards cannot withstand large currents; in the embodiment of the present invention, a plurality of interface plug-ins 8 are weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com