Oil returning cooling structure of electro-hydraulic servo valve

An electro-hydraulic servo valve and servo valve technology, applied in the field of electro-hydraulic servo, can solve problems such as increased leakage, decreased magnetic permeability of soft magnetic materials, and jamming, so as to improve stability and life, reduce working environment temperature, and guarantee Achieving and Safe Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

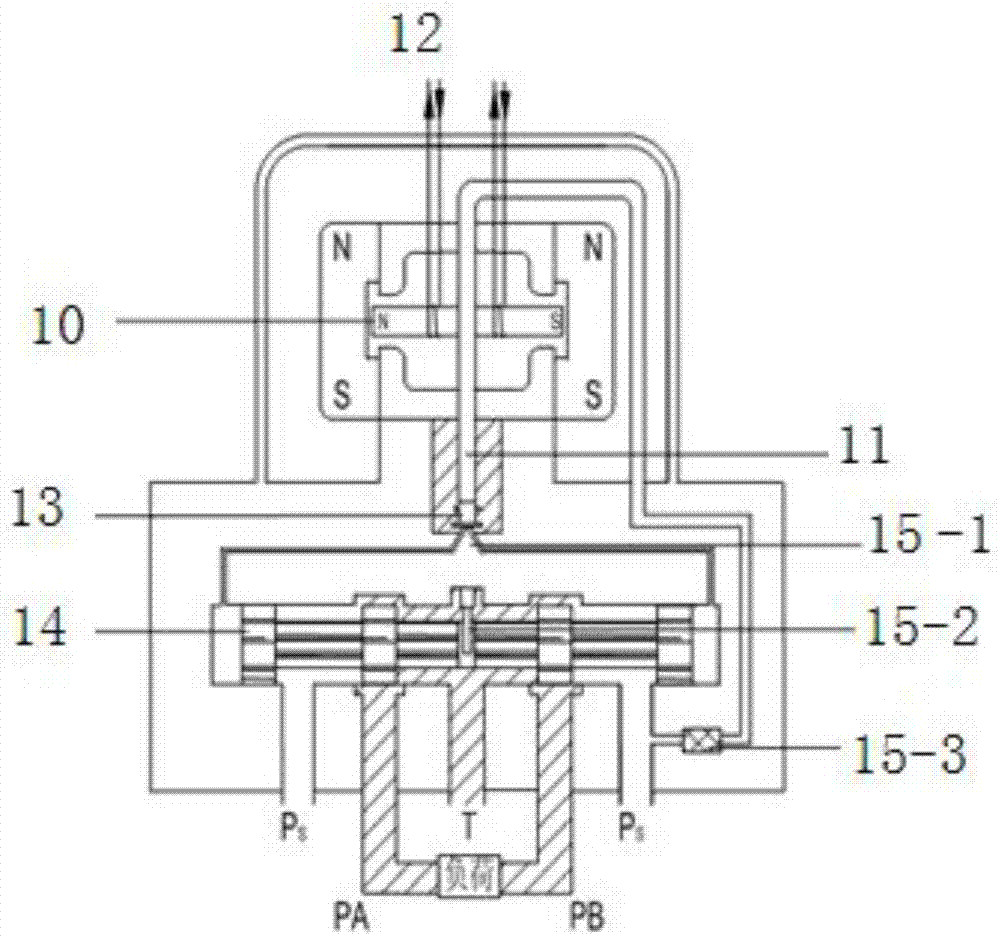

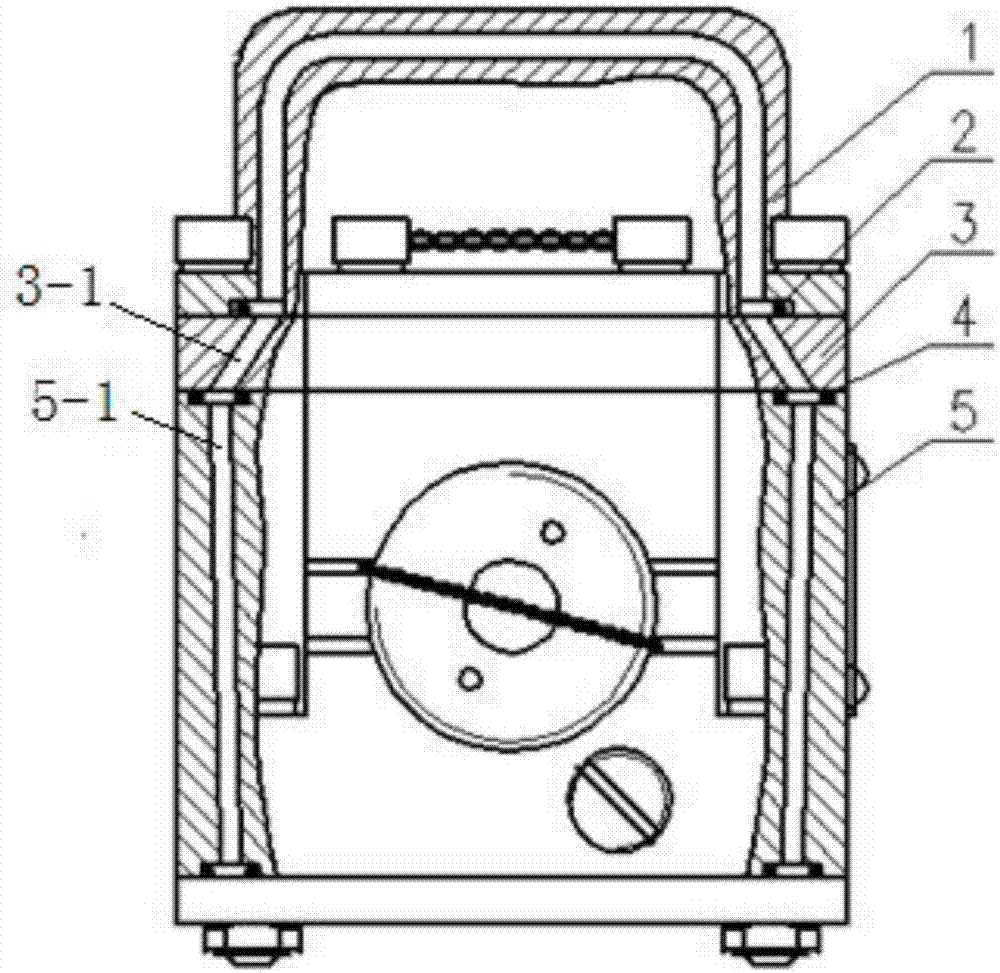

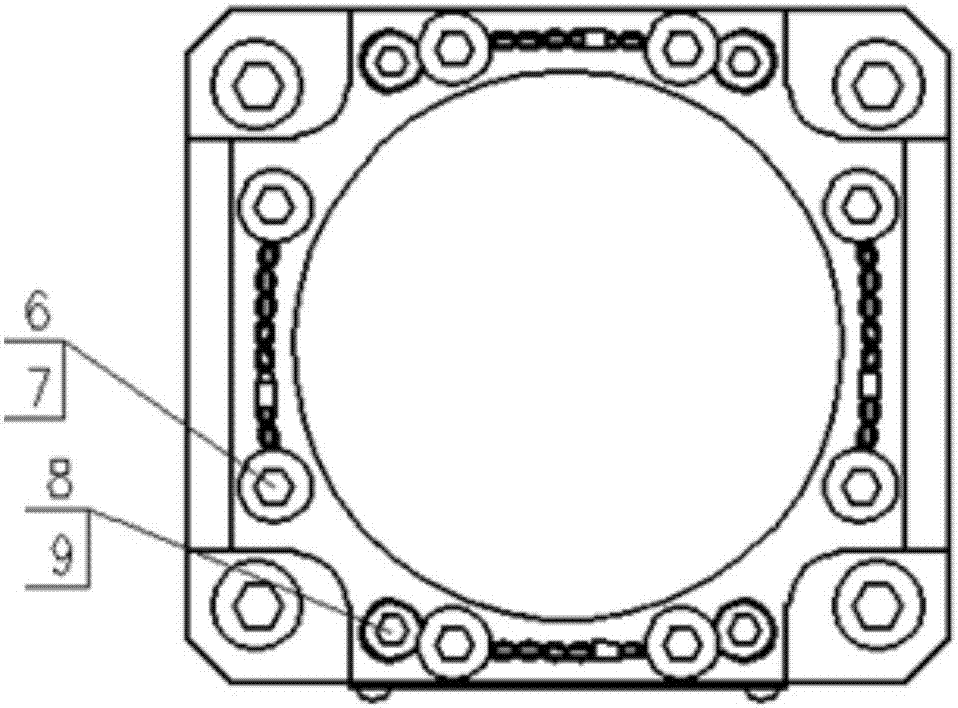

[0025] Such as Figure 2 to Figure 8 As shown, an oil return cooling structure of an electro-hydraulic servo valve includes a bushing 1, an upper cover 3, and a servo valve body 5. A through hole is respectively opened on both sides of the oil inlet cavity and the oil return cavity of the servo valve body 5. 5-1, the upper end of the servo valve body 5 is sealed and fixedly connected to the upper cover 3, and the upper end of the upper cover 3 is sealed and fixedly connected to the bushing 1, and the bushing and the upper cover are overlapped to form a cavity, and the cavity passes through the outer circle of the upper cover 3 The inclined holes 3-1 on both sides and the through holes 5-1 on both sides of the oil inlet chamber and the oil return chamber of the servo valve body 5 communicate with the oil inlet chamber and the oil return chamber of the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com