Fracture fixing steel plate and steel plate fixing system

A technology for fixing steel plates and fixing systems, which is applied in the field of medical devices, can solve problems such as not smooth, poor fixing effect, and limited operating space, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

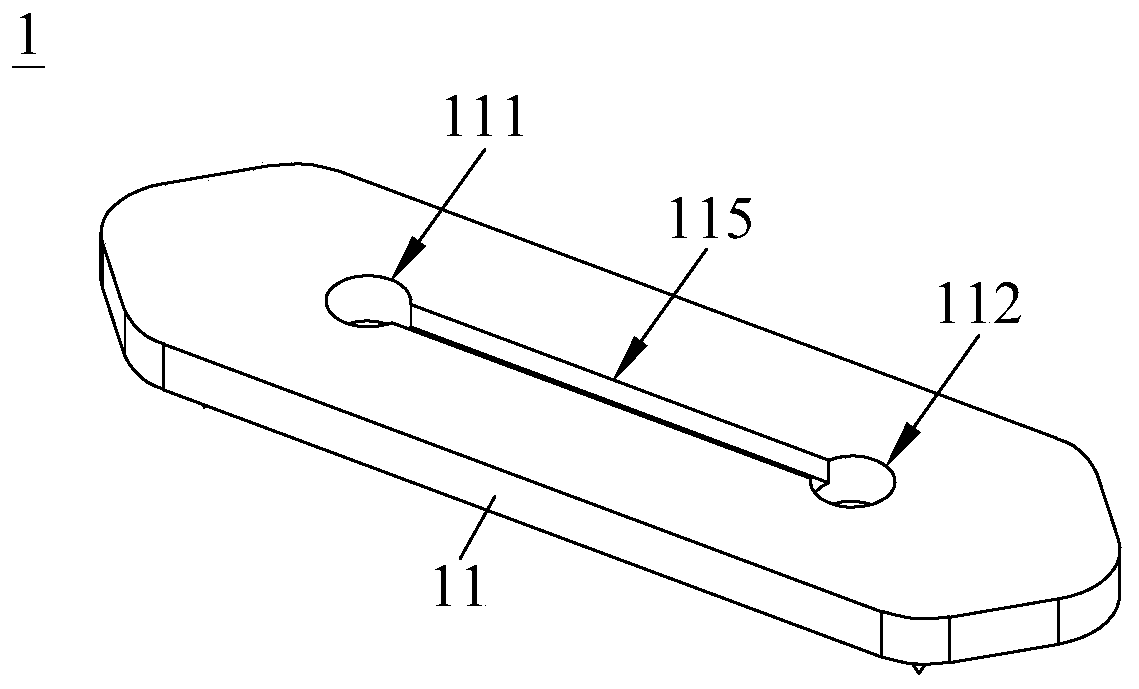

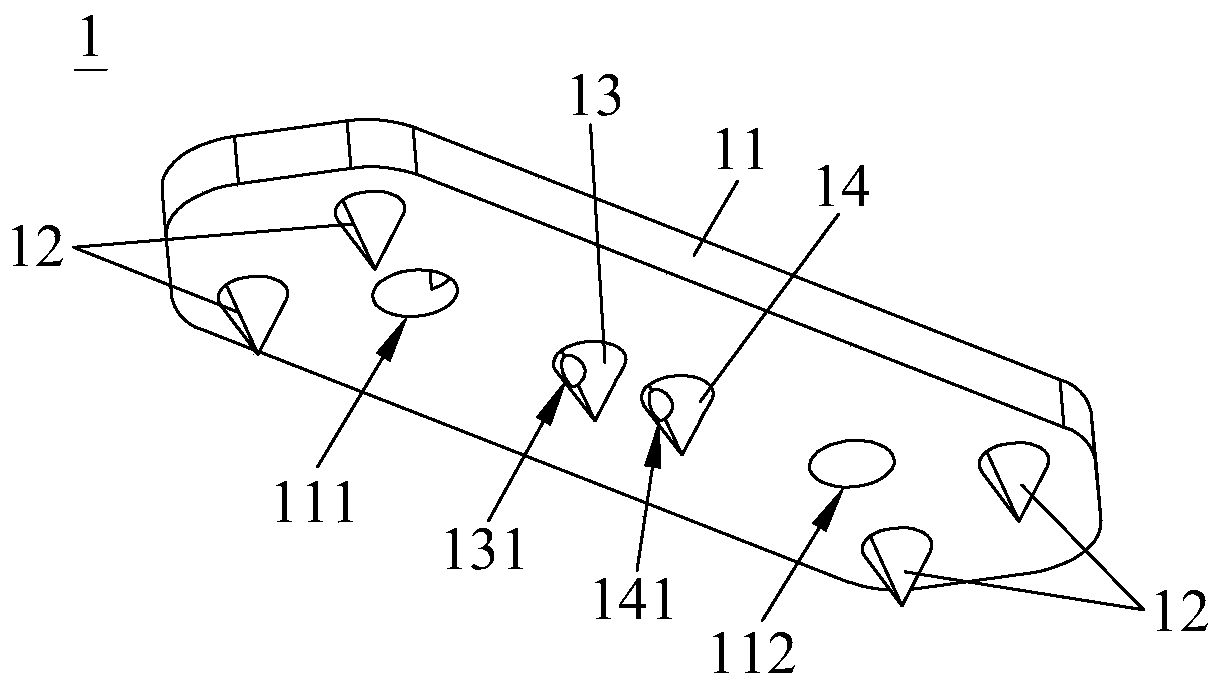

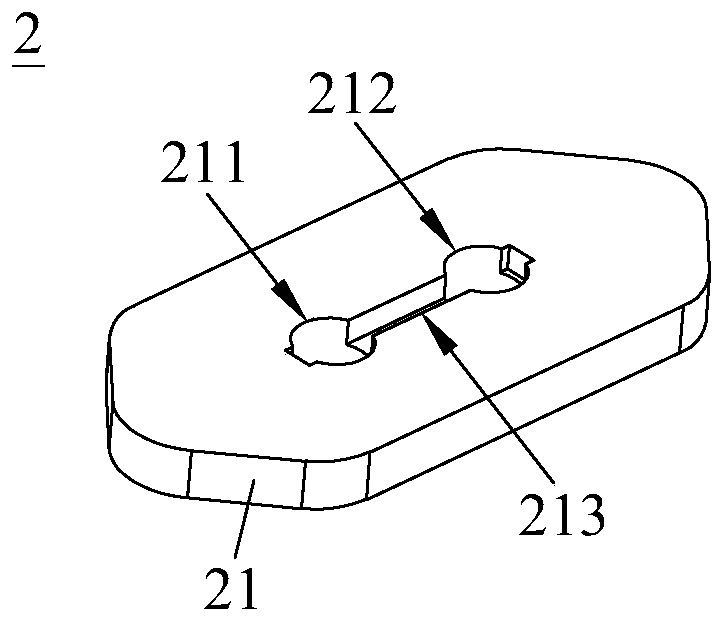

[0029] see Figure 6 and Figure 7, the plate fixation system 100 of the present invention includes two fracture fixation plates and steel wires 3 , wherein one fracture fixation plate is the first plate 1 , and the other fracture fixation plate is the second plate 2 . The first steel plate 1 includes a first steel body portion 11 and a first fixing portion 12 for positioning the first steel body portion 11. The first steel body portion 11 is provided with a first through hole that runs through its first surface and its second surface. Holes 111 and second through holes 112, the first fixing part 12 is arranged on the second surface of the first steel body part 11, the shape of the first steel body part 11 is not limited to the straight plate shape, the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com