Multichannel feeding and forming machine

A molding machine and multi-channel technology, applied in the field of extrusion conveyors, can solve the problems that are not mentioned and cannot meet the actual production needs, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

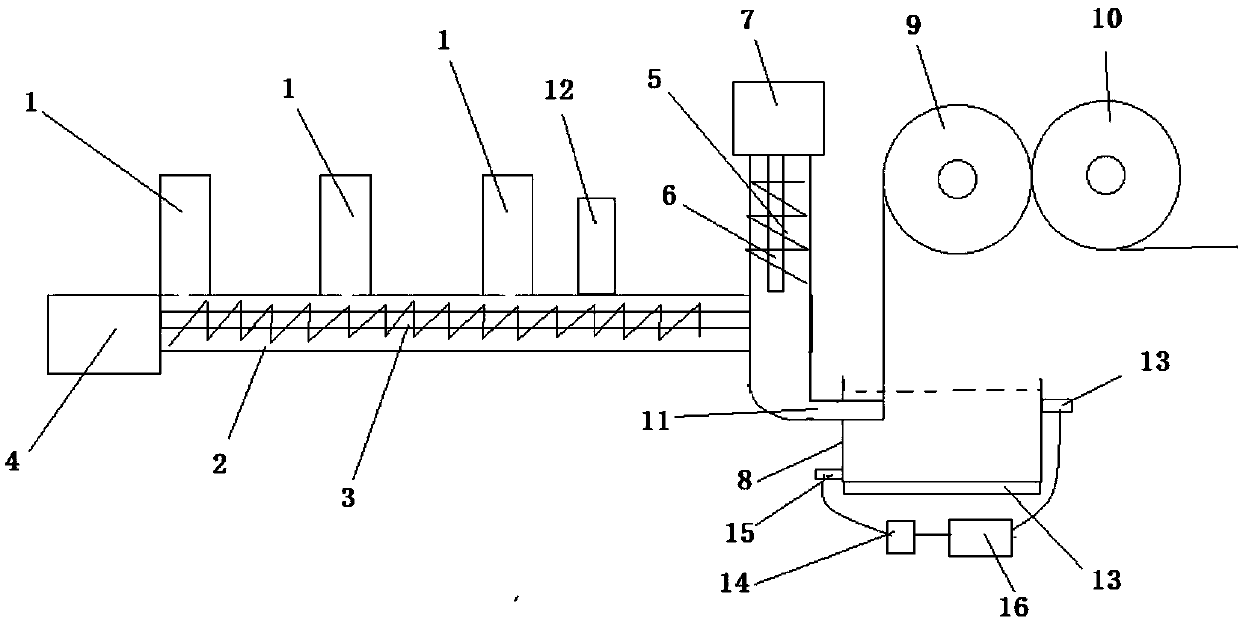

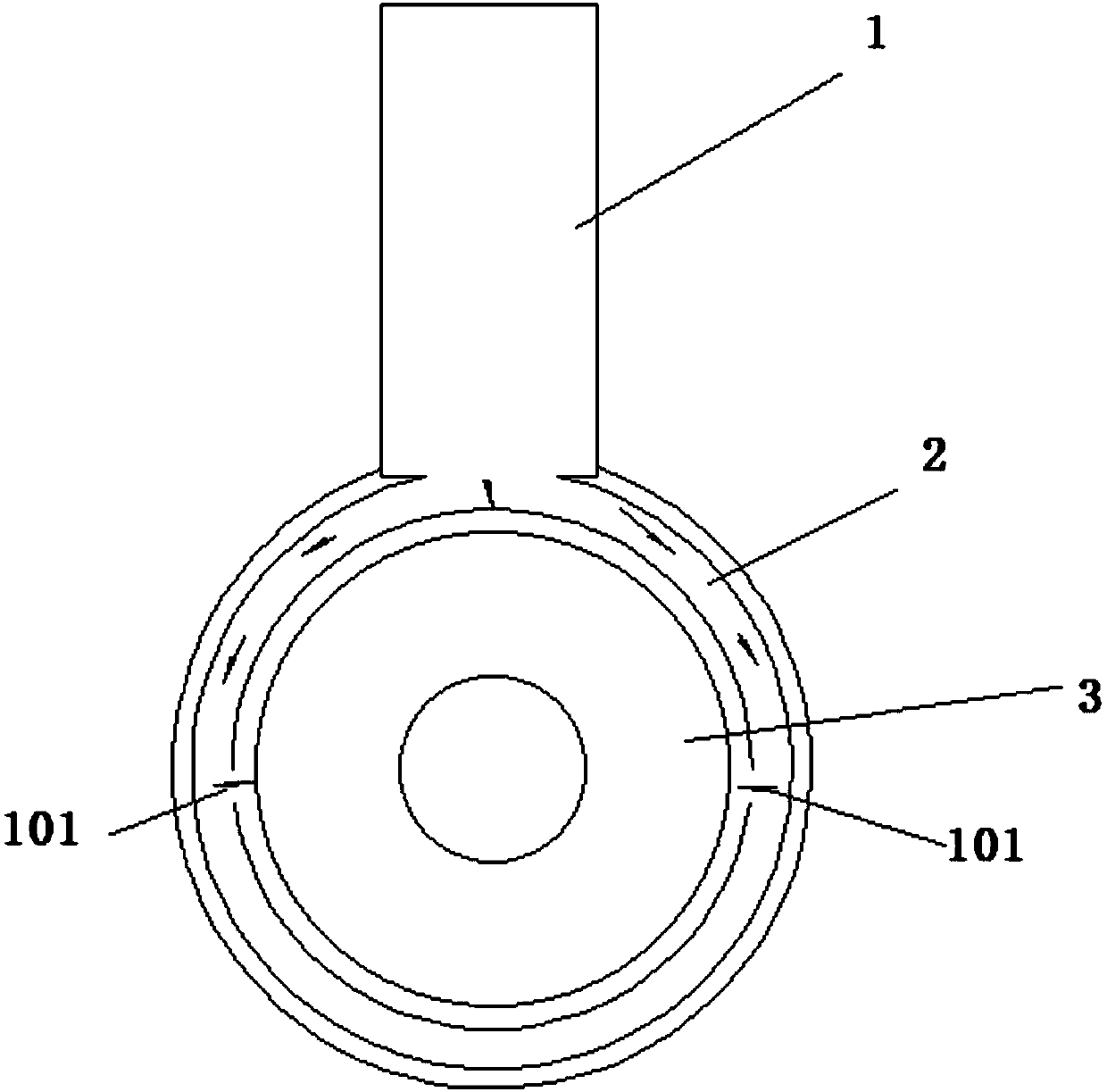

[0012] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the present invention includes a first screw conveyor section 2, a heating wire is arranged on the outside of the first screw conveyor section 2, a screw conveyor roller 3 is arranged on the inside, and a plurality of feeding ports 1 are arranged on the upper side; one end of the screw conveyor roller 3 Connected to the first motor 4; the first screw conveying section and the second screw conveying section are vertically arranged, and the material chambers of the two conveying sections are also connected vertically; the second motor 7 is arranged on the upper end of the second screw conveying section 5, and the inner The second screw roller 6, the lower end of the cavity in the second screw conveying section 5 is connected with the discharge port 11; the discharge port 11 is arranged in the cooling water tank 8, and cooling water is set in the cooling wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com