High-performance heat-resistant combustion-supporting glass fiber reinforced nylon extrusion molding device

An extrusion molding, high-performance technology, applied in the field of extrusion molding equipment of high-performance heat-resistant and combustion-supporting glass fiber reinforced nylon, can solve the problems of poor fluidity, fluidity gap, and inability to generate base pressure, etc., and achieve high control accuracy, The effect of uniform temperature and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

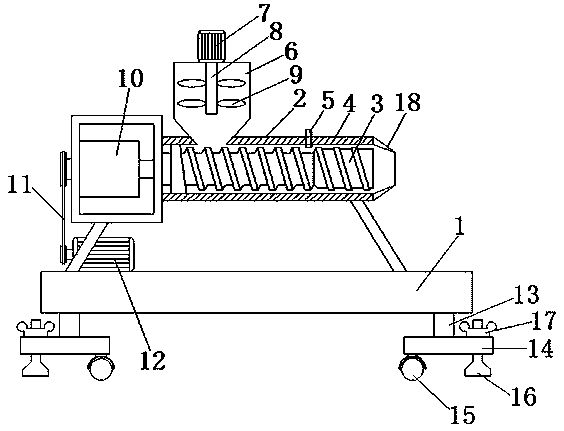

[0023] refer to figure 1 , a high-performance heat-resistant combustion-supporting glass fiber reinforced nylon extrusion molding equipment, including a base 1 and an extruder arranged on the base 1, the extruder includes a barrel 2, and a speed reducer arranged at one end of the barrel 2 Machine 10, a second motor 12 arranged on the base 1 and connected to the reducer 10 through a belt 11, an extrusion screw 3 arranged in the barrel 2, one end of the extrusion screw 3 is connected to the reducer 10 in transmission , the second motor 12 drives the reducer 10 to work, and the reducer 10 drives the extrusion screw 3 to rotate. One end of the barrel 2 that is not provided with a speed reducer 10 is provided with a discharge port, the top of the barrel 2 is provided with a feed barrel 6, the outlet of the feed barrel 6 communicates with the barrel 2, and the material enters the feed barrel 6 from the feed barrel 6. barrel 2 and extruded by extrusion screw 3.

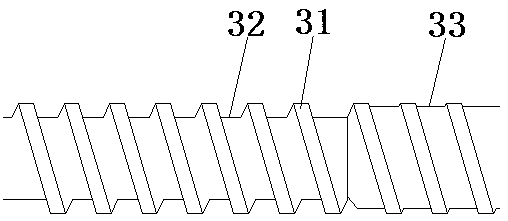

[0024] A transitio...

Embodiment 2

[0026] The heating wire 4 is wound on the surface of the barrel 2 to form a heating layer, and the heating wire 4 can heat the material in the barrel 2 to keep the material at a sufficient temperature and not condense because the temperature is too low. The heating layer is wrapped with a protective layer.

[0027] The barrel 2 is provided with a temperature sensor 5, the temperature sensor 5 is connected to a controller, and the heating wire 4 is also connected to the controller. The temperature sensor 5 detects the temperature in the barrel 2 in real time, and continuously sends the data to the controller. Then, the working state of the heating wire 4 is controlled by the controller to form a ring control system with high control precision, which realizes intelligent and automatic control of the temperature in the barrel 2, and can realize constant temperature, so that the material can maintain a suitable temperature, and will not be affected by the temperature. Too low and ...

Embodiment 3

[0029] The feeding barrel 6 is provided with a stirring device, which can stir the materials to keep the materials uniformly mixed and at a uniform temperature, and the quality of the extruded products is good. The agitating device includes a vertically arranged agitating shaft 8 and agitating blades 9 evenly distributed on both sides of the agitating shaft 8 , and the agitating shaft 8 is in transmission connection with the first motor 7 at the top of the feeding barrel 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com