A New Killing Method for Well Workover

A technology for workover and well killing, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc. Efficient and environmentally friendly development, inability to meet well killing needs, etc., to reduce on-site workover costs, improve long-term benefits, and reduce environmental protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

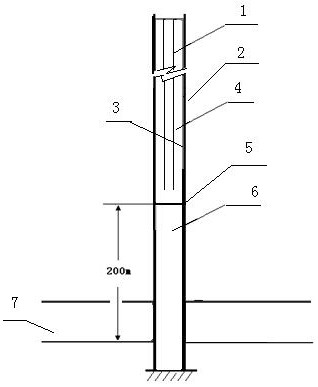

[0034] Such as figure 1 As shown, a new type of well killing method for well workover, first use the pump truck to pump the salt-containing fracturing fluid 4 from the casing 3 into the wellbore 2, after the salt-containing fracturing fluid 4 is filled with the wellbore 2, then pass through the tubing Mix the killing fluid and fine silt into the downhole, wherein the mass ratio of the fine silt to the total mixing amount is 2%-15%; the killing fluid will gradually thicken downhole, forming a length of The liquid rubber plug 6 that can seal liquid and gas can realize the plugging of oil and gas spillage. Among them, the fine silt will promote the formation of plugging at the bottom hole; after the pressure stabilization test is qualified, the workover operation will be implemented Finally, a gel breaker is added for backwashing and production.

[0035] The salt-containing fracturing fluid is composed of 1.5%~8.0% cationic gemini surfactant, 2.0%~15% KCl and 77.0%~96.5% H 2 O ...

Embodiment 2

[0040] Such as figure 1 As shown, a novel workover method for killing wells, the specific implementation steps are as follows:

[0041] Step 1: Operation preparation before well killing;

[0042] Step 2: pump saline fracturing fluid from the casing, and let the saline fracturing fluid fill the entire wellbore;

[0043] Step 3: Open the casing valve, pump the killing fluid containing fine silt from the tubing, and let the killing fluid flow back from the bottom of the well to the predetermined position, so that it can form in the wellbore between the bottom of the well and the predetermined position. A liquid rubber plug for sealing liquid and gas; the predetermined position is 200m upwards from the bottom of oil layer 7, wherein the kill fluid containing fine silt is mixed with fine silt, and the amount of fine silt accounts for the total mixed The mass ratio of the amount is 2%-15%;

[0044] Step 4: Close the casing valve;

[0045] Step 5: With less than 1m 3 Inject saline...

Embodiment 3

[0057] It is basically the same as Example 2, except that the salt-containing fracturing fluid is composed of 1.5% cationic gemini surfactant, 2.0% KCl and 96.5% H 2 O is mixed according to the above mass ratio.

[0058] The well killing fluid is composed of 1.5% cationic gemini surfactant, 0.2% sodium sulfosalicylate and 98.3% H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com