Engine lubricating system

A lubrication system and engine technology, which is applied in the direction of engine lubrication, engine components, engine cooling, etc., can solve the problems of reducing fuel consumption, high performance targets, and unreliable pistons, achieving energy saving and emission reduction effects, and high control flexibility , the effect of low difficulty in implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

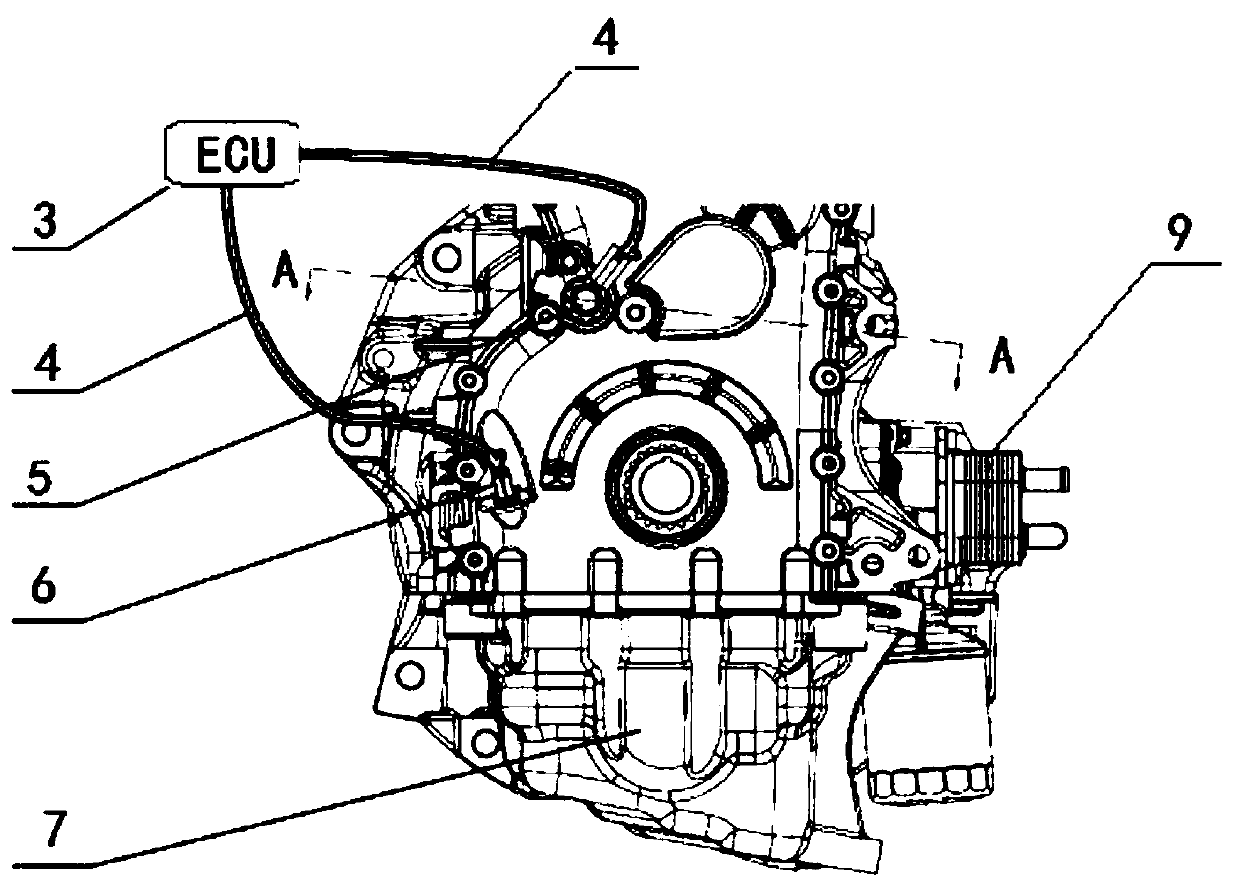

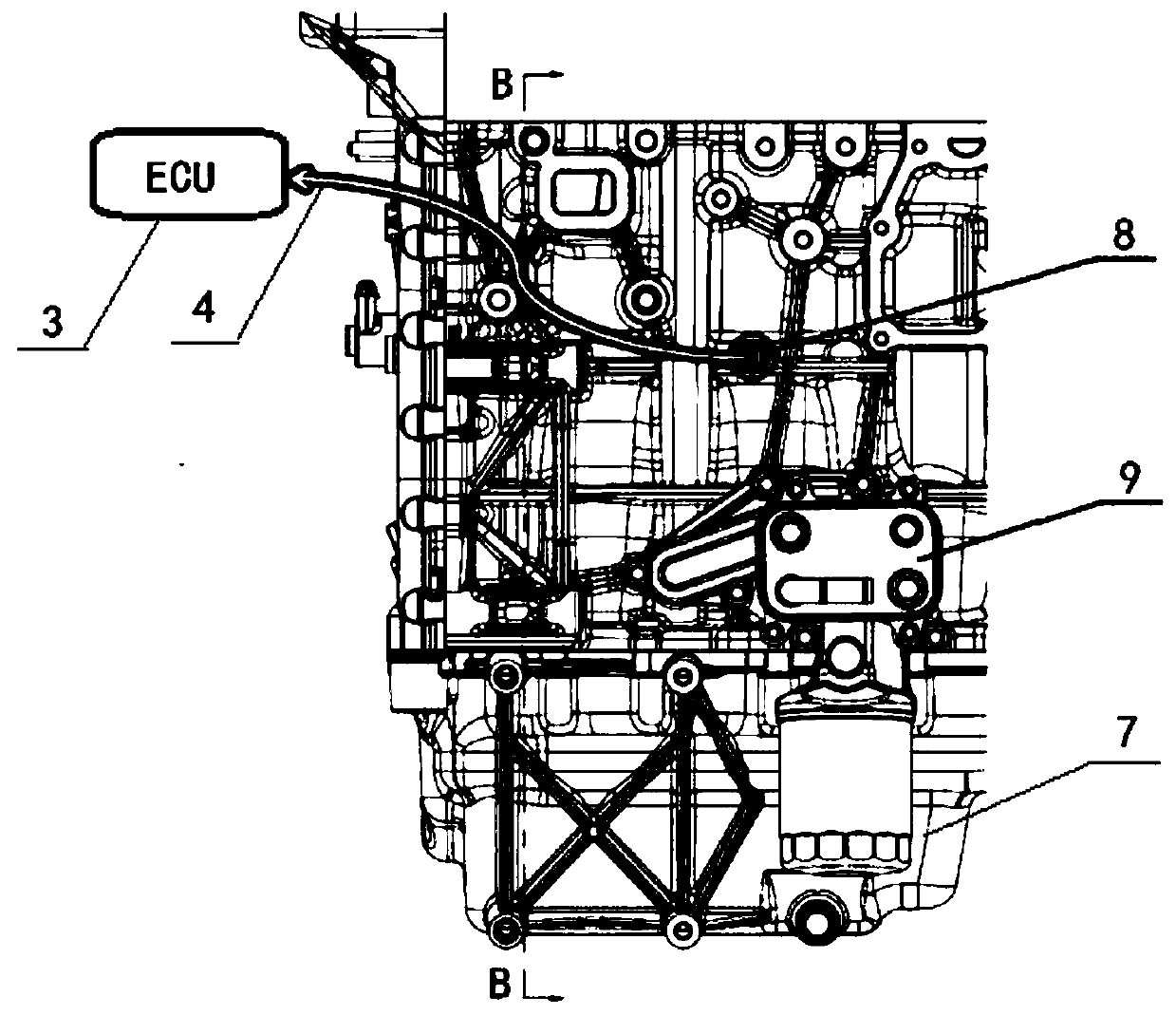

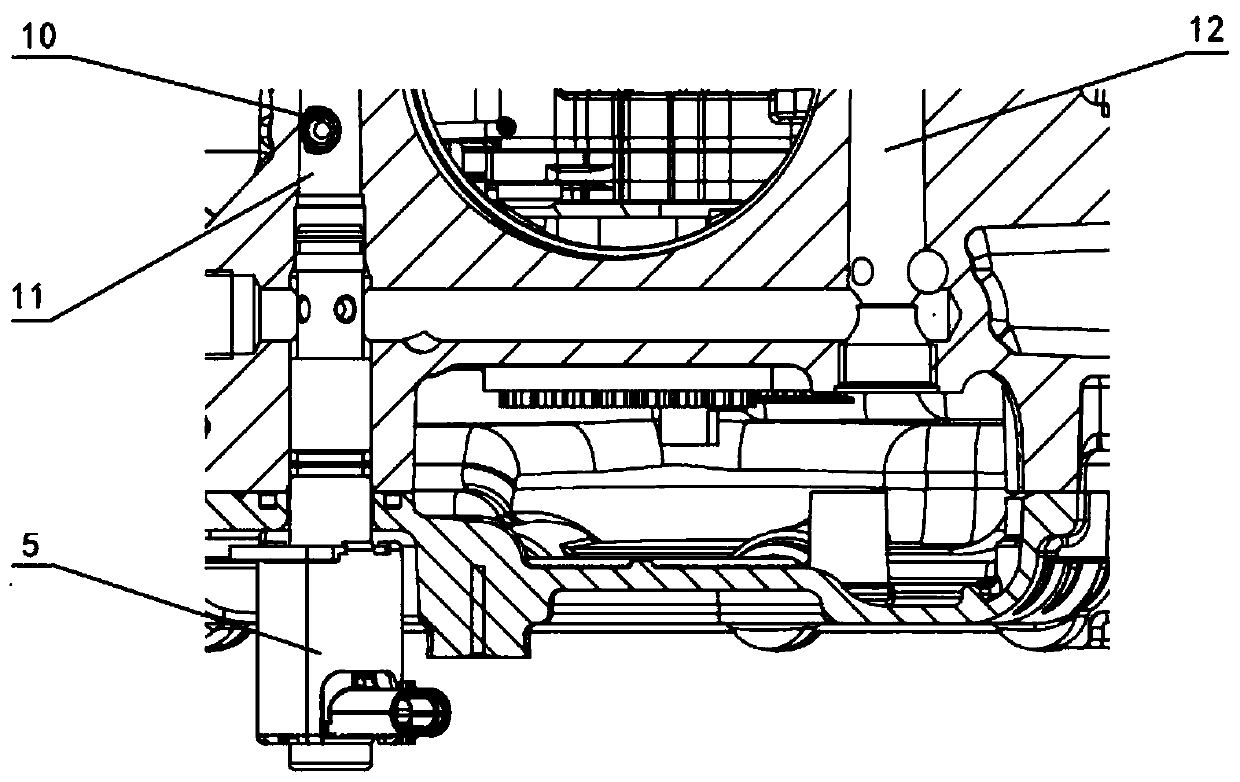

[0025] see Figure 1 to Figure 6 The engine lubricating system shown includes: a piston cooling nozzle oil passage 11 arranged on the engine block, a cylinder main oil passage 12 and a cylinder feedback oil passage 15, a control unit 3 arranged outside the engine, installed on The engine oil pan 7 below the engine block, the fully variable oil pump 14 located between the engine block below and the oil pan 7, the fully variable oil pump is the energy source of the entire lubricating system, and provides a sufficient amount of lubricating oil for the lubricating system. Its characteristics are:

[0026] An oil pressure oil temperature sensor 8 is installed on the main oil passage 12 of the cylinder body to sense the pressure and temperature of the engine oil, and convert it into an electrical signal and transmit it to the control unit 3;

[0027] A piston cooling contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com