Tobacco shred elasticity detection method and tobacco shred elasticity detector

A technology of elasticity detection and detection instrument, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that cannot truly reflect the elasticity of shredded tobacco, eliminate large shorts, and have no elasticity, etc., so as to improve detection accuracy and detection Efficiency, high measurement accuracy, and the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

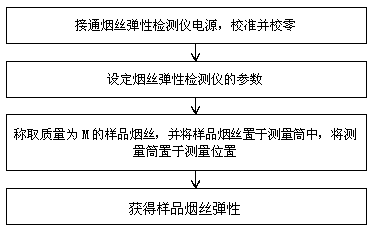

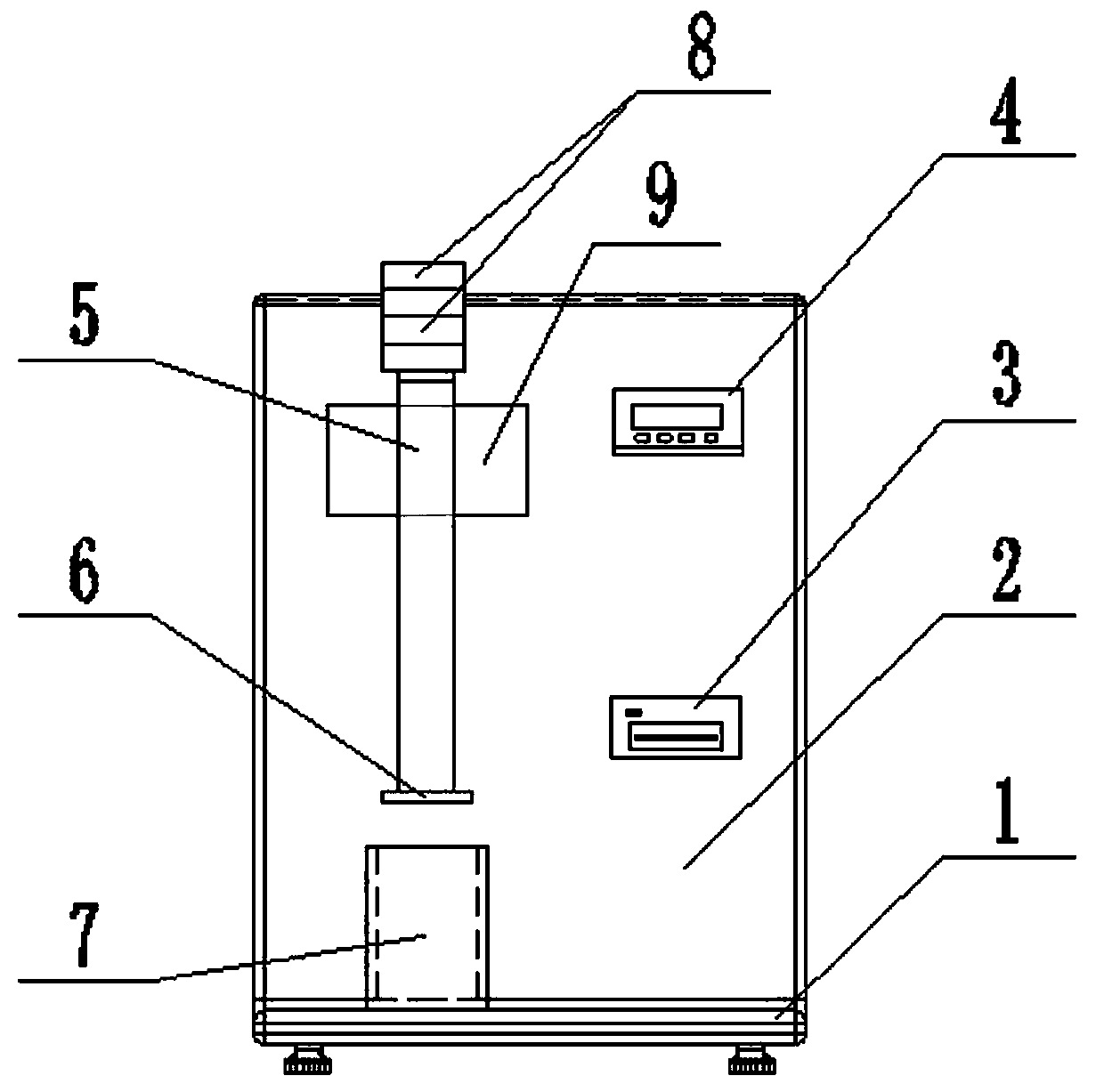

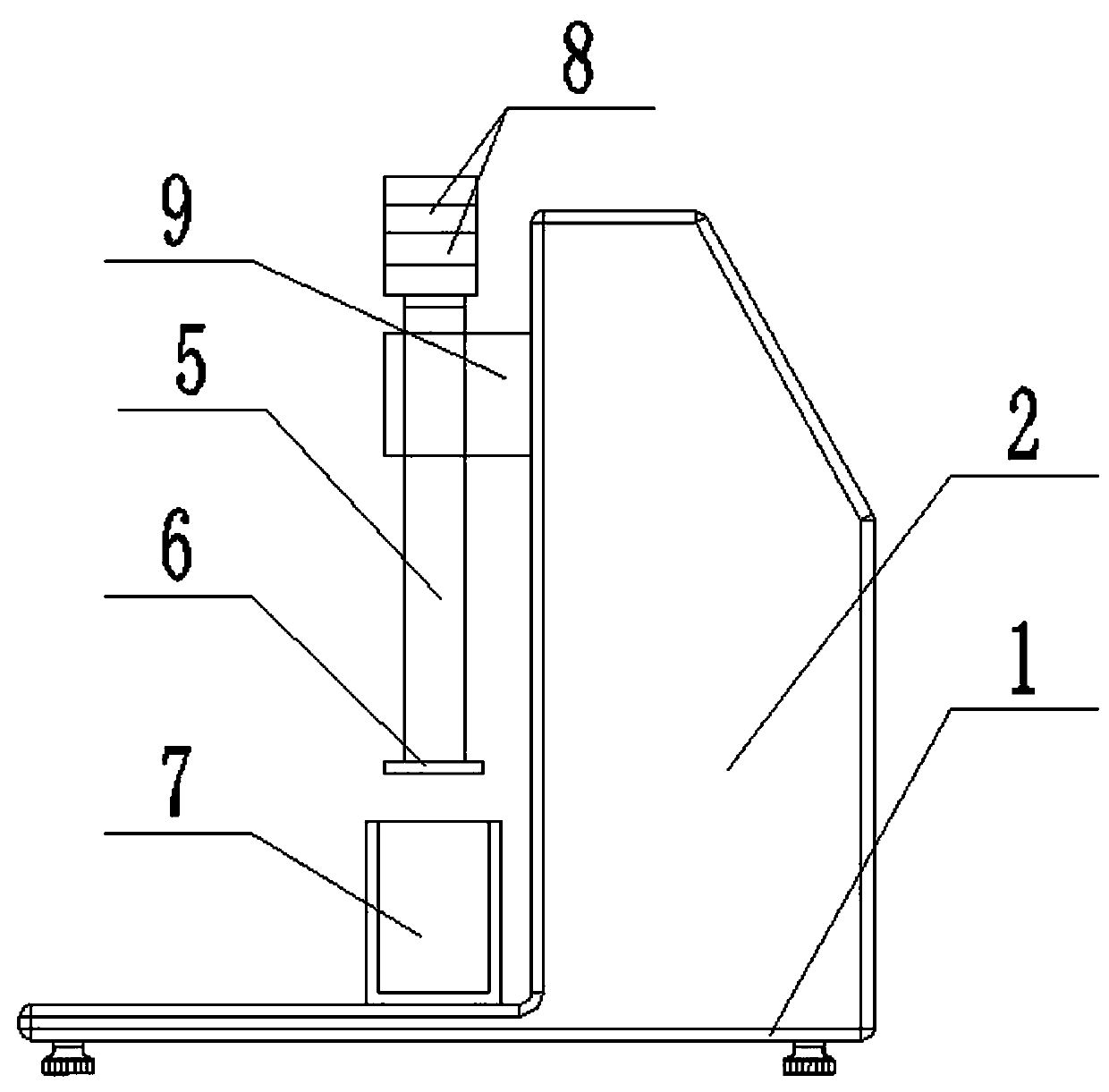

[0032] Such as figure 1 As shown, the present invention includes a method for detecting elasticity of shredded tobacco, comprising the following steps:

[0033] Step 1: Turn on the power of the shredded tobacco elasticity detector, calibrate and zero;

[0034] Step 2: Set the parameters of the shredded tobacco elasticity detector: set the pressing time of the shredded tobacco pressing mechanism as T 1 , the pressure height of shredded tobacco at the end of pressure is H 0 , the pressure release time of shredded tobacco after pressure application is T 2 ;

[0035] Step 3: Weigh the sample shredded tobacco with a mass of M, place the sample shredded tobacco in the measuring cylinder 7, and place the measuring cylinder 7 at the measuring position;

[0036] Step 4: Carry out shredded tobacco pressing and obtain test parameters: the detector control system controls the shredded tobacco pressing mechanism to move down at a constant speed T 1 time, the cut tobacco pressing mecha...

Embodiment 2

[0061] Such as Figure 5 As shown, in the described shredded tobacco elasticity detector, the shredded tobacco height measuring mechanism also includes a sensor mounting ring 10 fixedly sleeved on the sliding shaft 5; the lower wall of the sensor mounting ring 10 is fixedly provided with a plurality of ranging sensors 11, so The distance measuring sensors 11 are evenly arranged along the circumference of the installation ring; the pressing head 6 is provided with signal through holes 12 corresponding to the distance measuring sensors 11 one by one, and each signal through hole 12 is inlaid with a transparent plate, The lower end face of the transparent plate is flush with the lower end face of the pressing head 6 . The transparent plate can be made of glass fiber reinforced plastic.

[0062] During the process of pressing shredded tobacco by pressing head 6, friction will inevitably occur. Due to electrostatic adsorption, sometimes the lower end surface of pressing head 6 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com