Device and method for simulating gas flowing of matrix-crack system

A technology of gas flow and crack system, which is applied in the direction of measuring devices, suspension and porous material analysis, instruments, etc., and can solve the problems of immature gas flow simulation technology, inability to truly simulate gas flow process, singleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

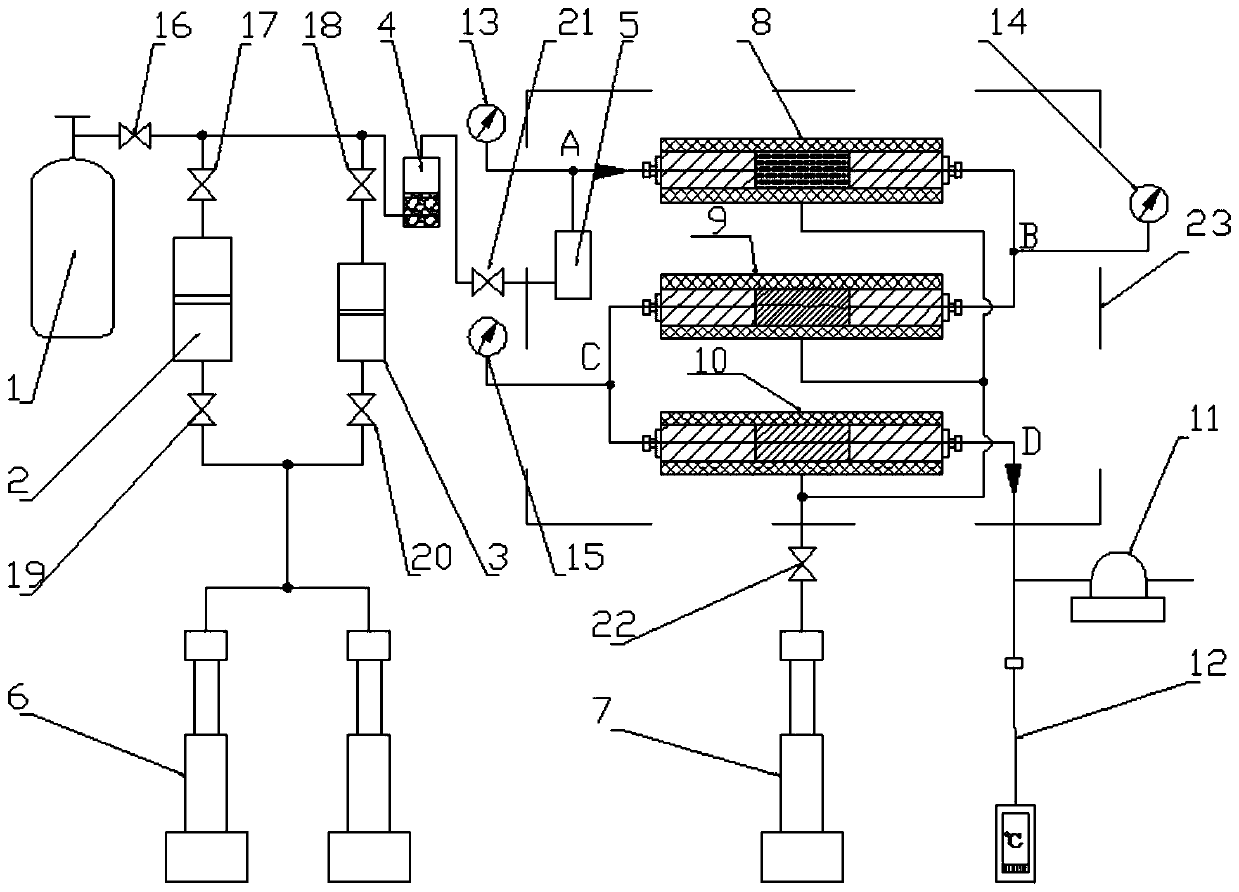

Method used

Image

Examples

Embodiment 1

[0086] For a tight gas reservoir, the reservoir depth is 2090m-4080m, the reservoir temperature is 80°C-120°C, the formation pressure is 38MPa-54MPa, the core matrix porosity is 2%-7%, and the overburden permeability is 10% -4 mD~10 -2mD, with developed structural fractures, increased production after acid fracturing.

[0087] Downhole cores were taken to prepare matrix cores and natural fracture cores, and a core combination with a matrix core-natural fracture core permeability ratio of about 1:2 was selected, combined with split artificial steel blocks to form a matrix-fracture system, and placed in sequence in the In the three-stage core holder, the confining pressure is applied, and the core is wrapped with a rubber sleeve.

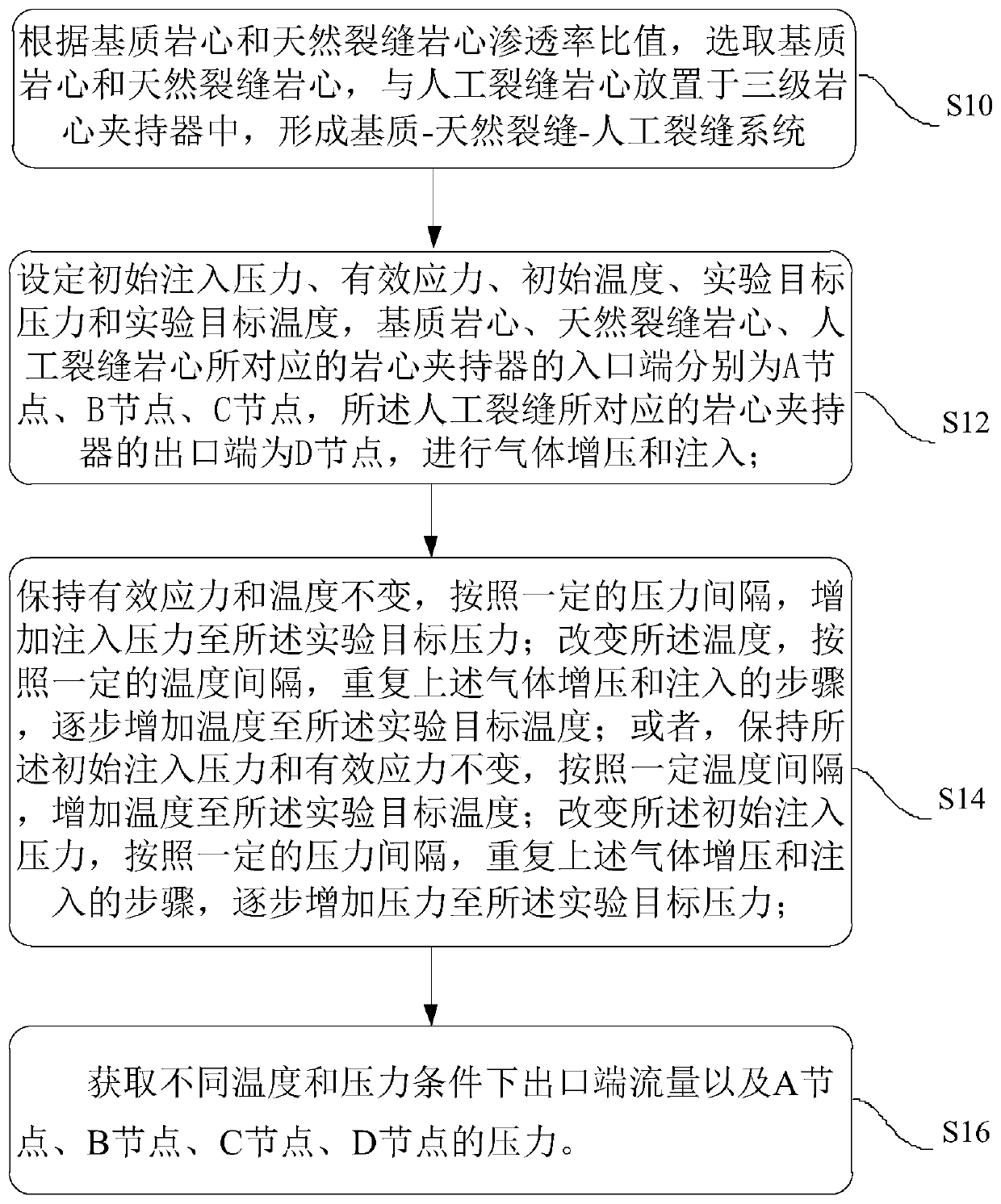

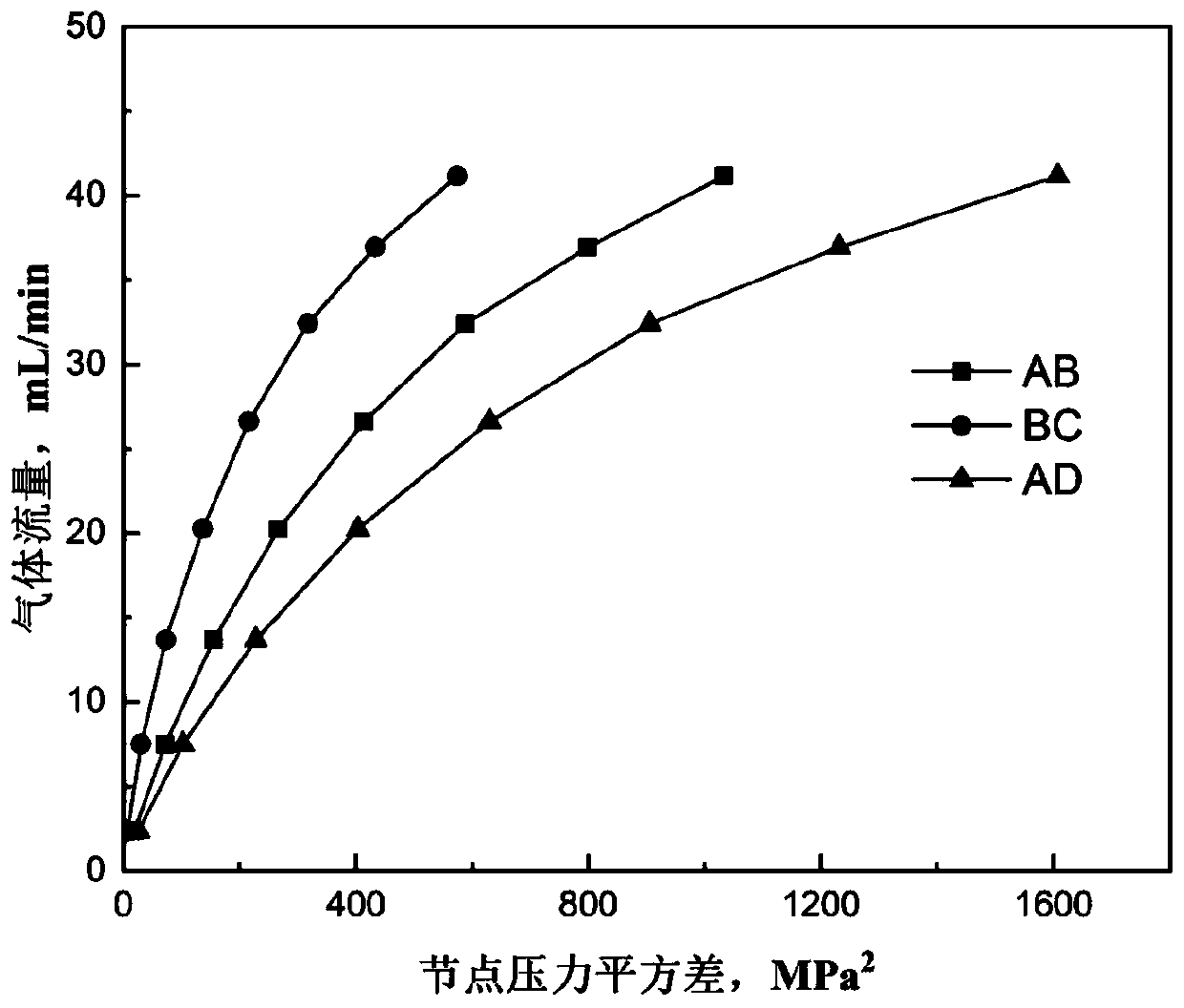

[0088] The experimental temperature is 80°C, the initial gas pressure is 5MPa, the effective stress is 10MPa, and the gas pressure is gradually increased to 40MPa at intervals of 5MPa; under each gas pressure, when the pressure indication numbers of ...

Embodiment 2

[0092] The selected research area is a high temperature and high pressure tight gas reservoir, the reservoir depth is 6000m-8000m, the reservoir temperature is 120°C-180°C, the formation pressure is 90MPa-140MPa, the core matrix porosity is 4.3%-5.5%, and the overburden Pressure permeability is less than 10 -4 mD~10 -2 mD, with developed structural fractures, increased production after acid fracturing.

[0093] Downhole coring, drilling matrix cores and natural fracture cores, selecting a core combination with a matrix core-natural fracture core permeability ratio of about 1:27, combining with split artificial steel blocks to form a matrix-fracture system, and placing them in order Put it in the three-stage core holder, apply confining pressure, and wrap the core with a rubber sleeve.

[0094] In order to ensure the safety of the experiment as much as possible, the experimental temperature is 80°C, the initial gas pressure is 10MPa, the effective stress is 10MPa, and the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com