Product detection system and method

A detection system and product technology, applied in measuring devices, optical testing flaws/defects, image data processing, etc., can solve problems such as low detection efficiency and high misjudgment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

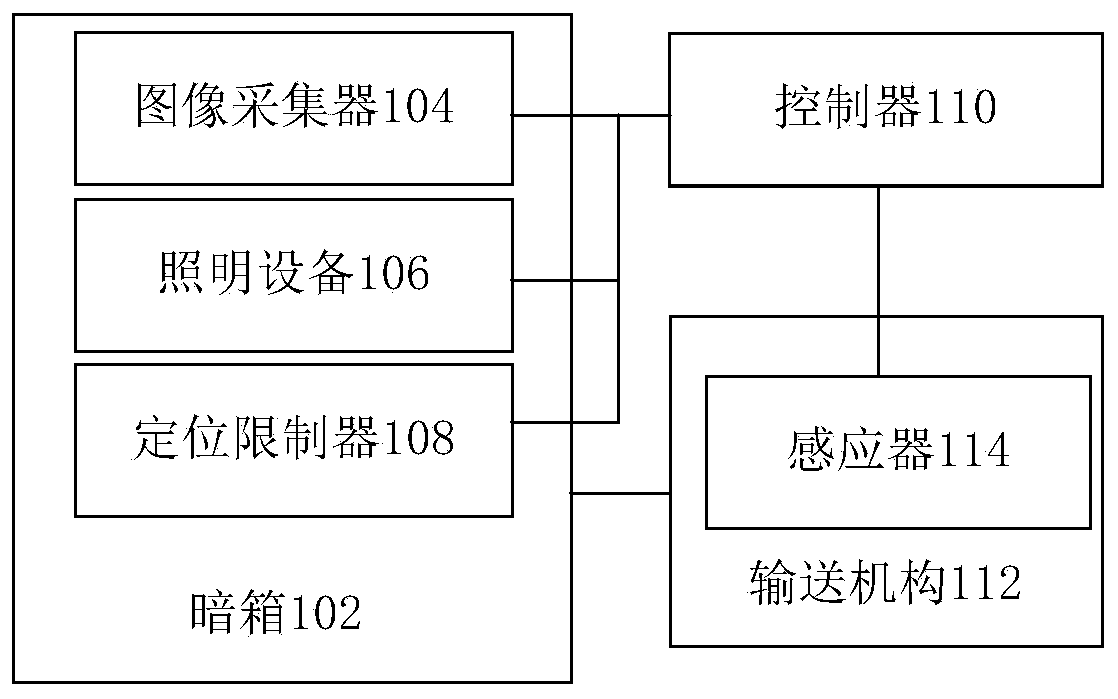

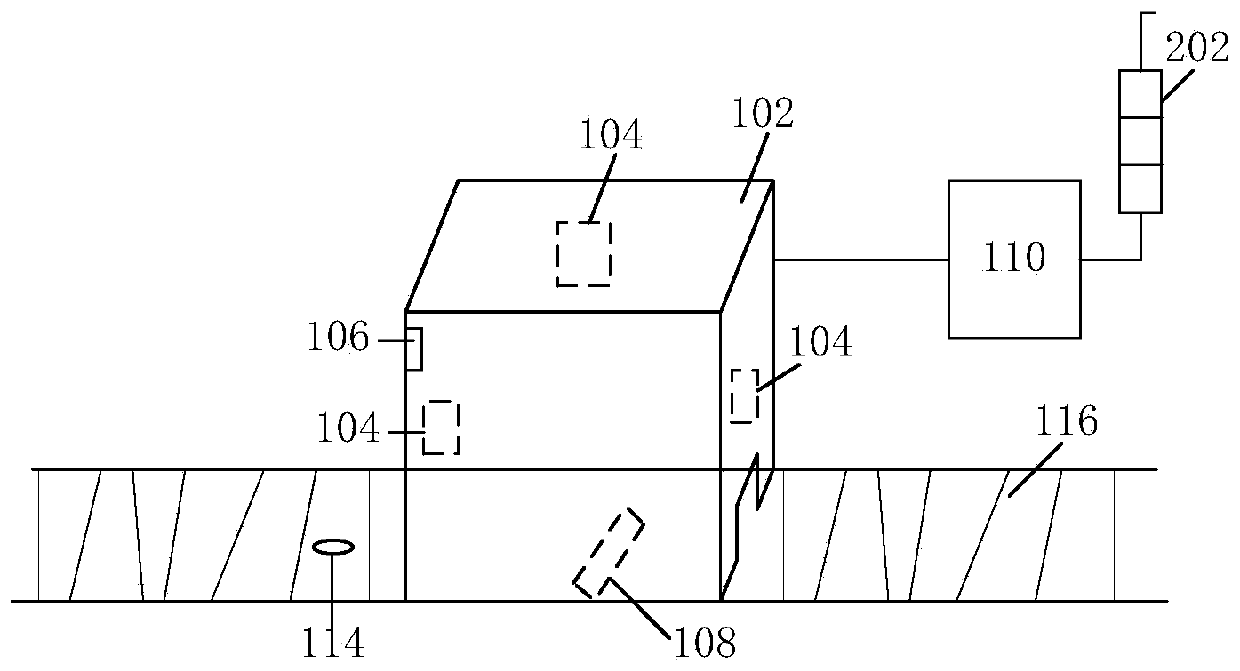

[0030] This embodiment provides a product detection system, refer to figure 1 Shown is a structural schematic diagram of a product inspection system, the system includes a dark box 102, an image collector 104 arranged on the dark box 102, an illumination device 106 and a positioning limiter 108, and also includes an image collector 104 and a positioning limiter 108 A controller 110 connected to both, and a conveying mechanism 112 connected to the controller 110; a sensor 114 is set at a designated position of the conveying mechanism 112;

[0031]During specific implementation, the dark box 102 is used to prevent factors such as light in the external environment from affecting the acquisition of the image data of the target product; the conveyor belt 116 of the conveying mechanism 112 passes through the entrance 102a and the exit 102b of the black box 102; wherein, the entrance 102a and the exit 102b are not exist figure 1 The lighting device 106 is used to provide lighting fo...

Embodiment 2

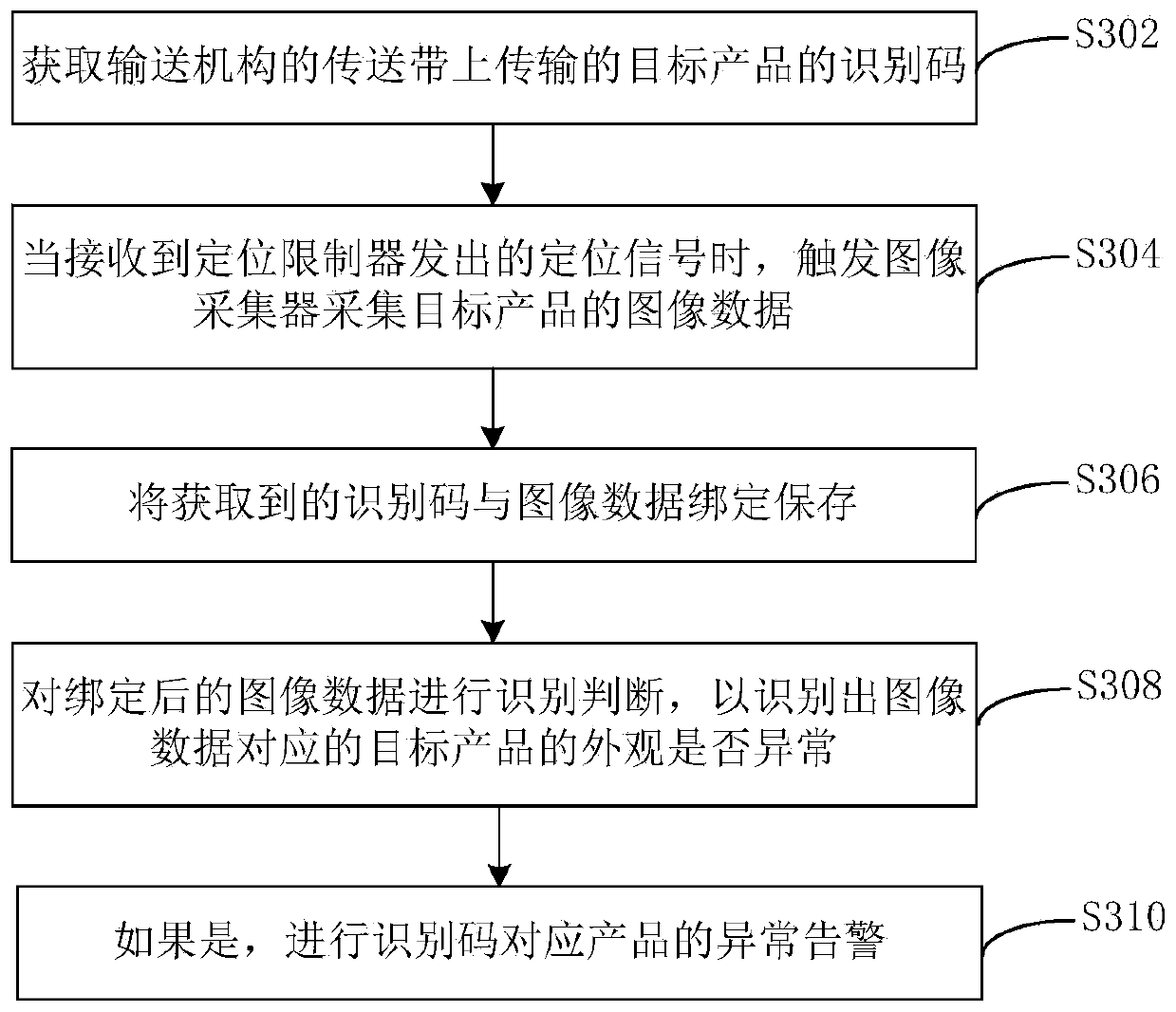

[0047] On the basis of the product detection system provided in Embodiment 1, this embodiment provides a product detection method, refer to image 3 A flow chart of a product detection method is shown, the method is applied to the controller in the product detection system described in Embodiment 1, the controller is connected with an image collector, a positioning limiter and a conveying mechanism, and the method consists of the following Steps to achieve:

[0048] Step S302, acquiring the identification code of the target product transported on the conveyor belt of the transport mechanism;

[0049] Step S304, when receiving the positioning signal sent by the positioning limiter, trigger the image collector to collect the image data of the target product; wherein, the positioning signal is a signal sent by the positioning limiter to limit the target product on the conveyor belt in the dark box;

[0050] Step S306, binding and saving the acquired identification code and image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com