High-safety peanut baking and stir-frying machine for food processing

A food processing and high-safety technology, applied in the field of food processing, can solve the problems of easy splashing of peanuts when heated, scalding workers, burning peanuts, etc., to improve the safety of use, ensure safety, and improve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

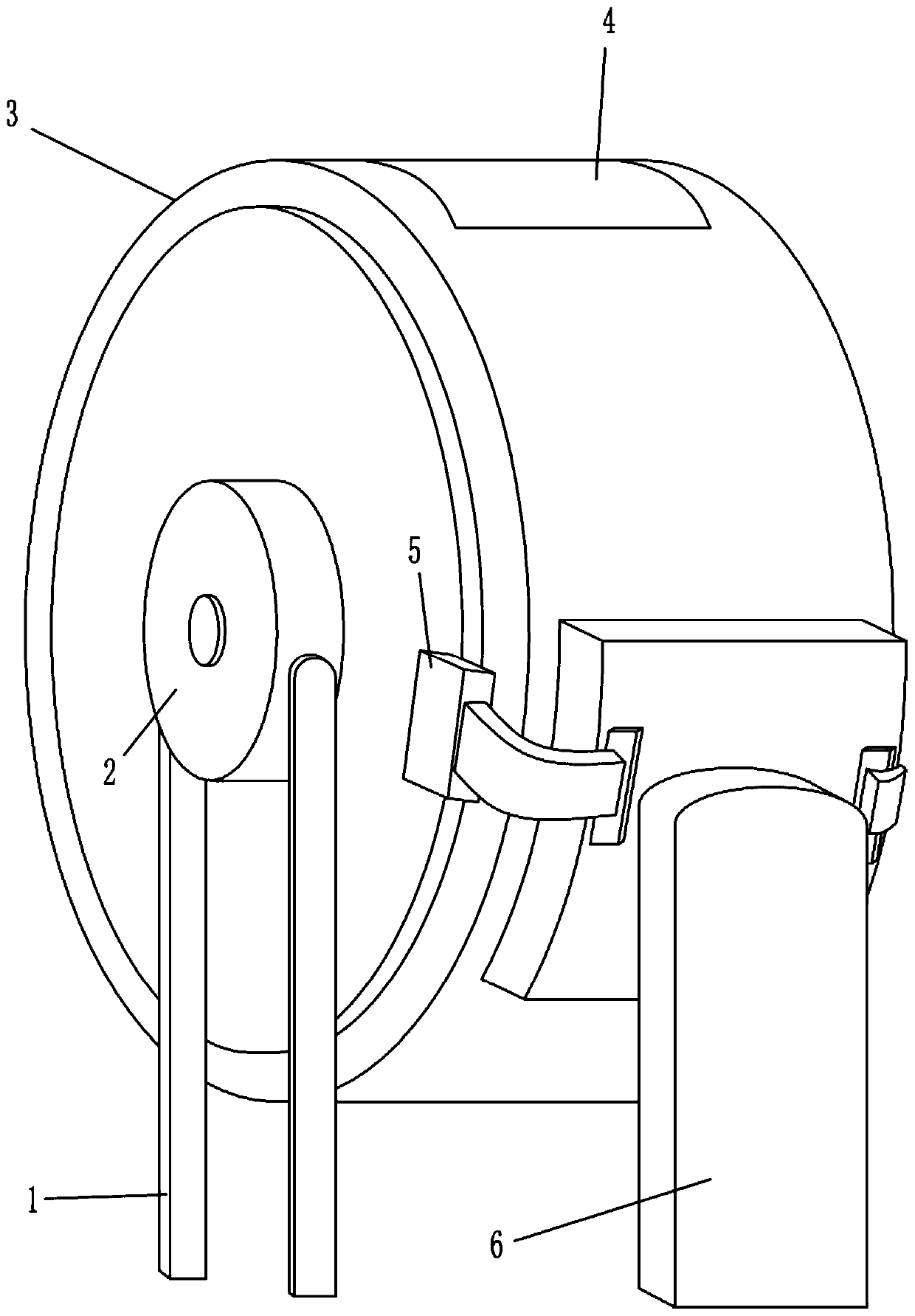

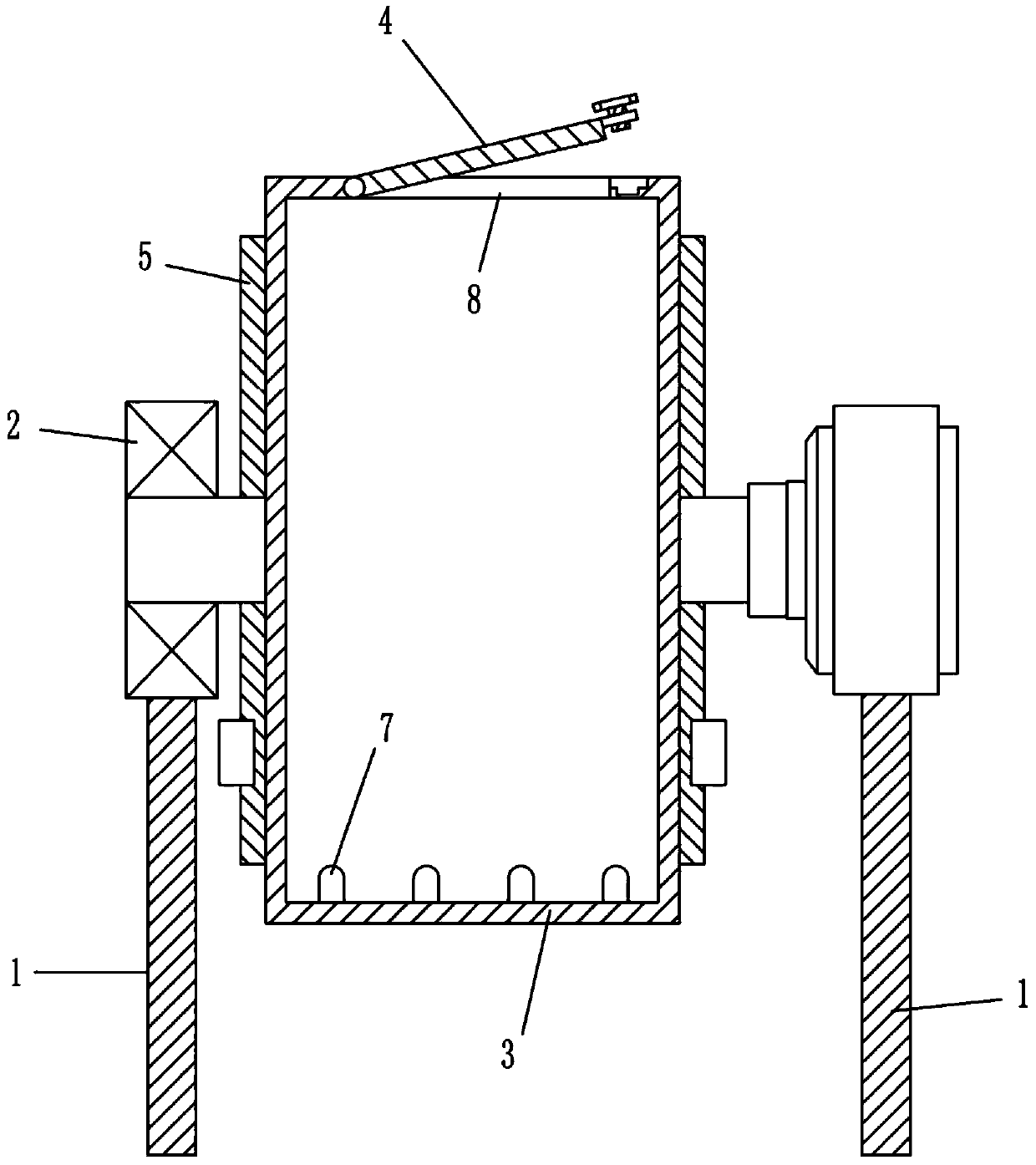

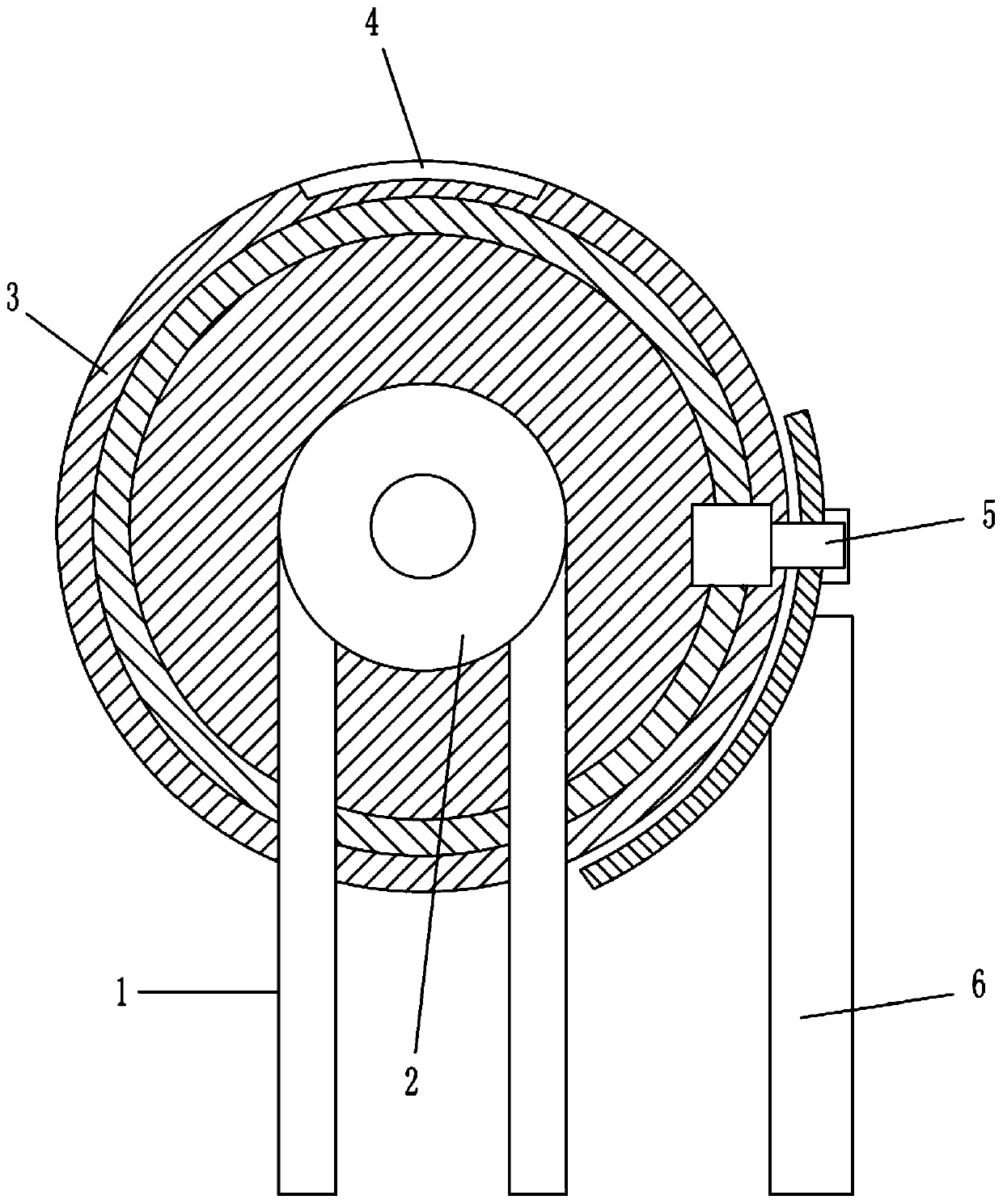

[0037] A high-safety peanut frying machine for food processing, such as Figure 1-9 As shown, it includes a mounting frame 1, a rotating part 2, a processing cylinder 3, a blanking part 4, a heating part 5, a support frame 6 and a separation column 7; the rotating part 2 is fixed on the top of the mounting frame 1; the processing cylinder 3 and the rotating The output end of component 2 is connected by transmission, and the processing cylinder 3 is provided with a feed port 8; the blanking part 4 is fixedly connected to the processing cylinder 3, and the blanking part 4 covers the feed port 8; the separation column 7 is uniformly fixed on the processing cylinder 3 inner wall; the heating component 5 is fixedly connected to the top of the support frame 6, and the heating component 5 is slidably connected with the processing cylinder 3.

[0038] Food processing refers to grain grinding, feed processing, vegetable oil and sugar processing, slaughtering and meat processing, aquati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com