Feeding device and method of integrated circuit chip testing and sorting machine

A chip testing and feeding device technology, applied in sorting and other directions, can solve the problems of low production efficiency of semiconductor device testing tapes, small size of semiconductor devices, and high difficulty, and achieves high practicability, simple and convenient operation, and stable and reliable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

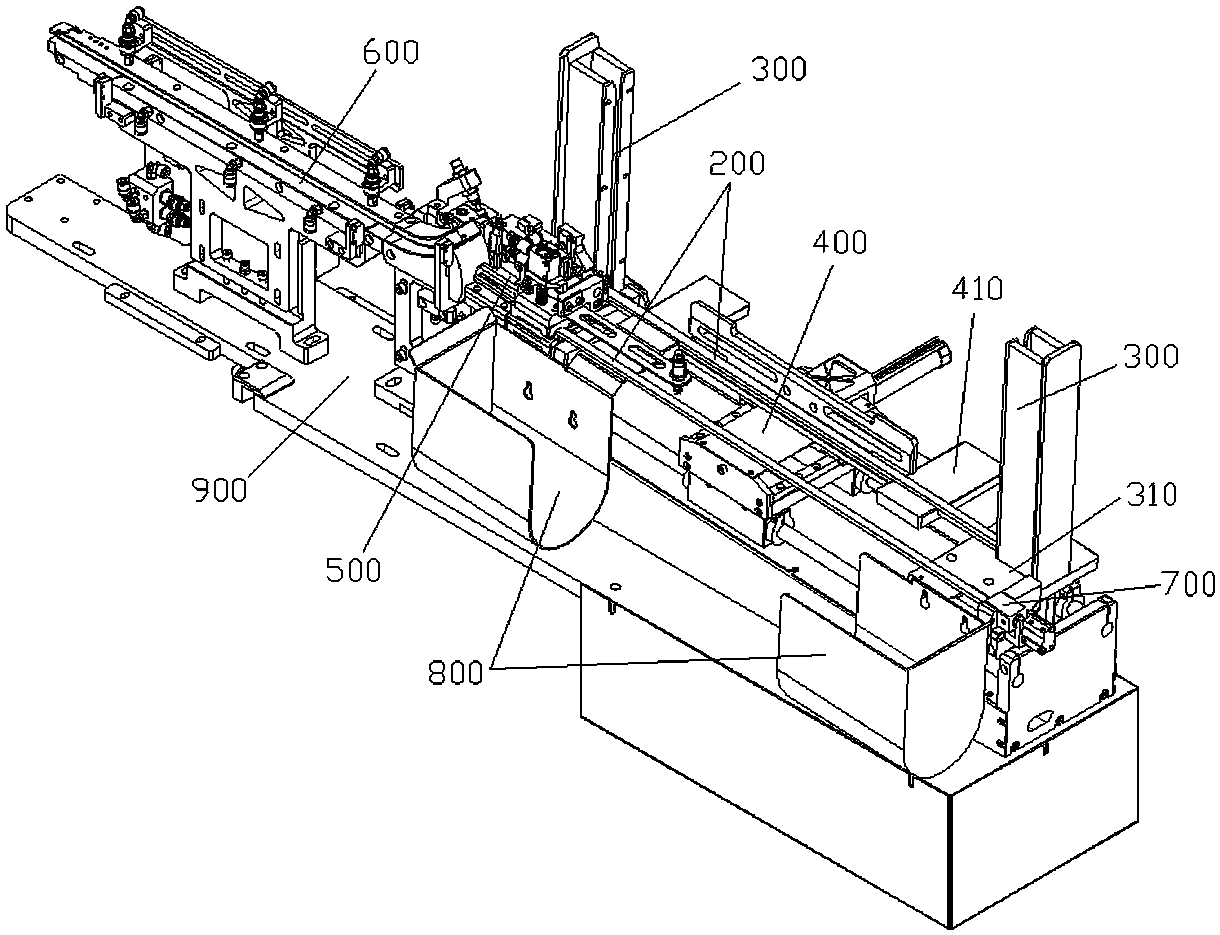

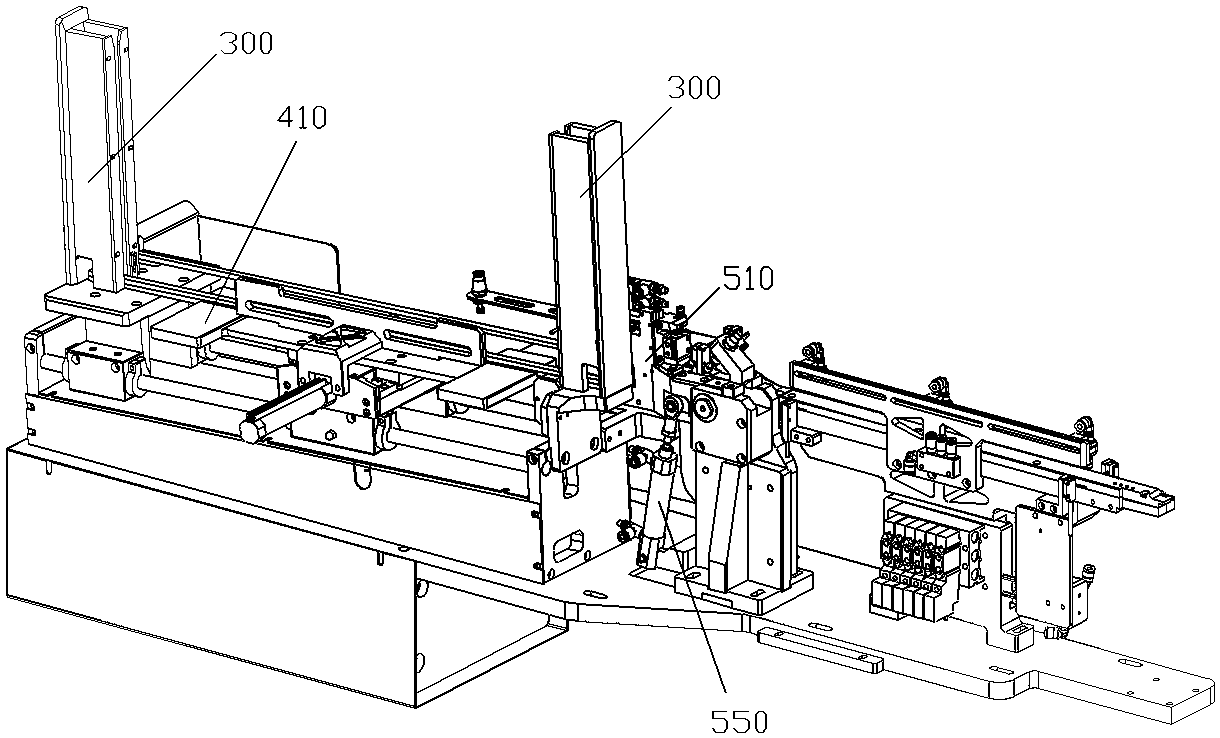

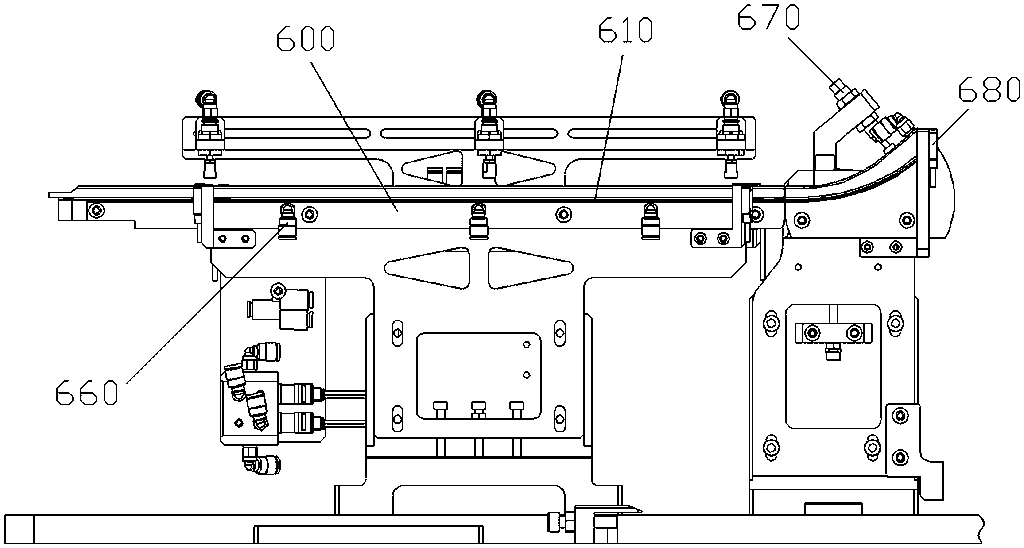

[0026] Such as Figure 1~11 As shown, a feeding device for an integrated circuit chip test sorter includes a frame 900, on which a trough 300 for vertically stacking packaging tubes 200 with semiconductor devices 100 is installed on the frame 900, for The packaging tube for accommodating semiconductor devices is an existing technology, and will not be elaborated again; the internal size of the packaging tube is slightly larger than the size of the semiconductor device, and the semiconductor device can slide freely in the packaging tube. Arranged in a row; two troughs 300 are erected at both ends of the packaging tube, and the two ends of the packaging tube extend into the trough; the side of the bottom of the trough 300 has an outlet for a single packaging tube to pass through 310, a pushing mechanism 400 is provided below the trough 300 to push the lowermost packaging tube from the discharge port; a swing mechanism 500 is provided on the side of the front end of the trough to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com