Tube socket leading wire flattening device

A tube base lead and tube base technology, which is applied in the field of tube base lead processing equipment, can solve the problems of device accuracy affecting work efficiency, reduced flattening accuracy, and low work efficiency, so as to avoid failure to grasp the tube base and flattening accuracy High, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

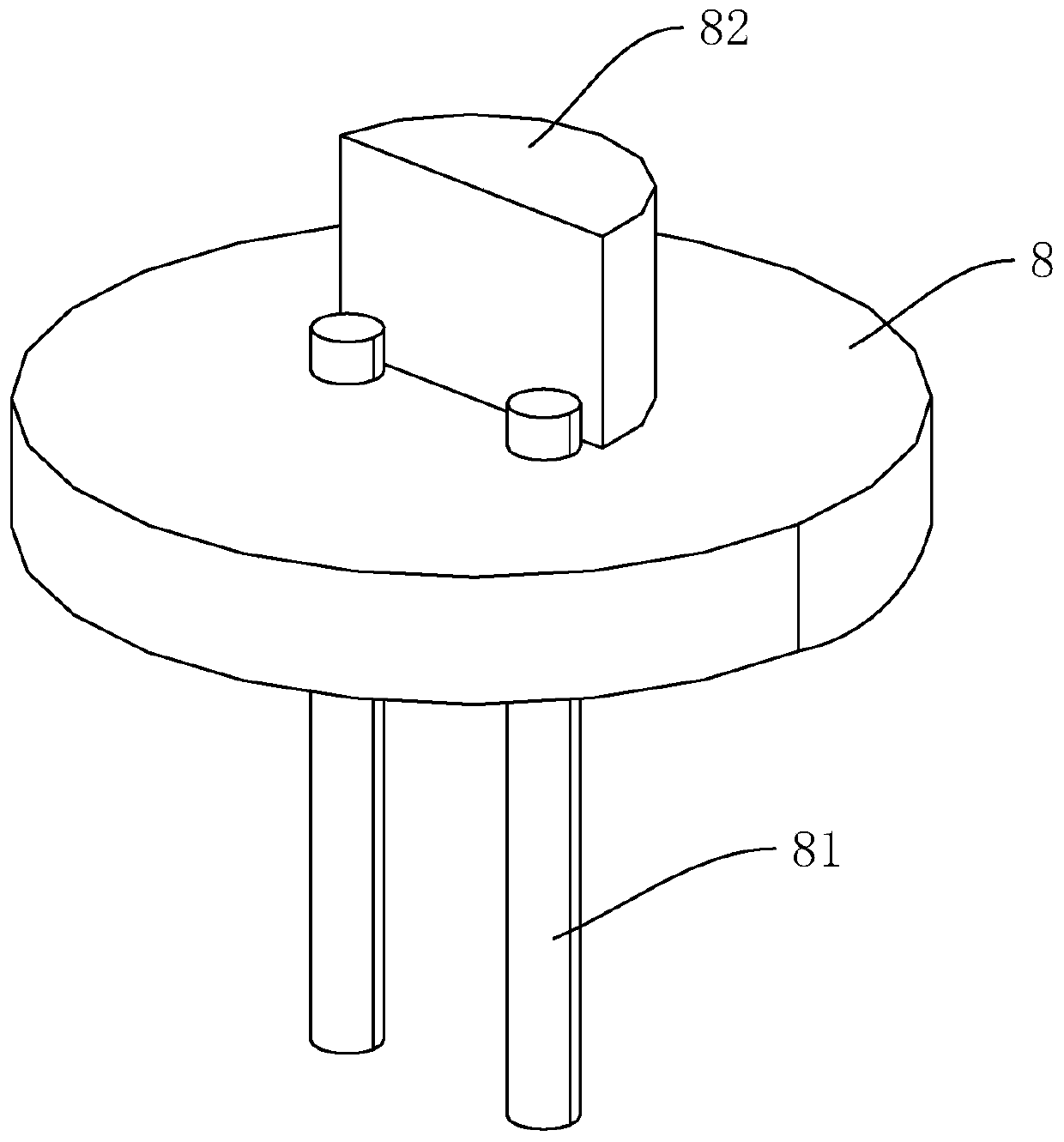

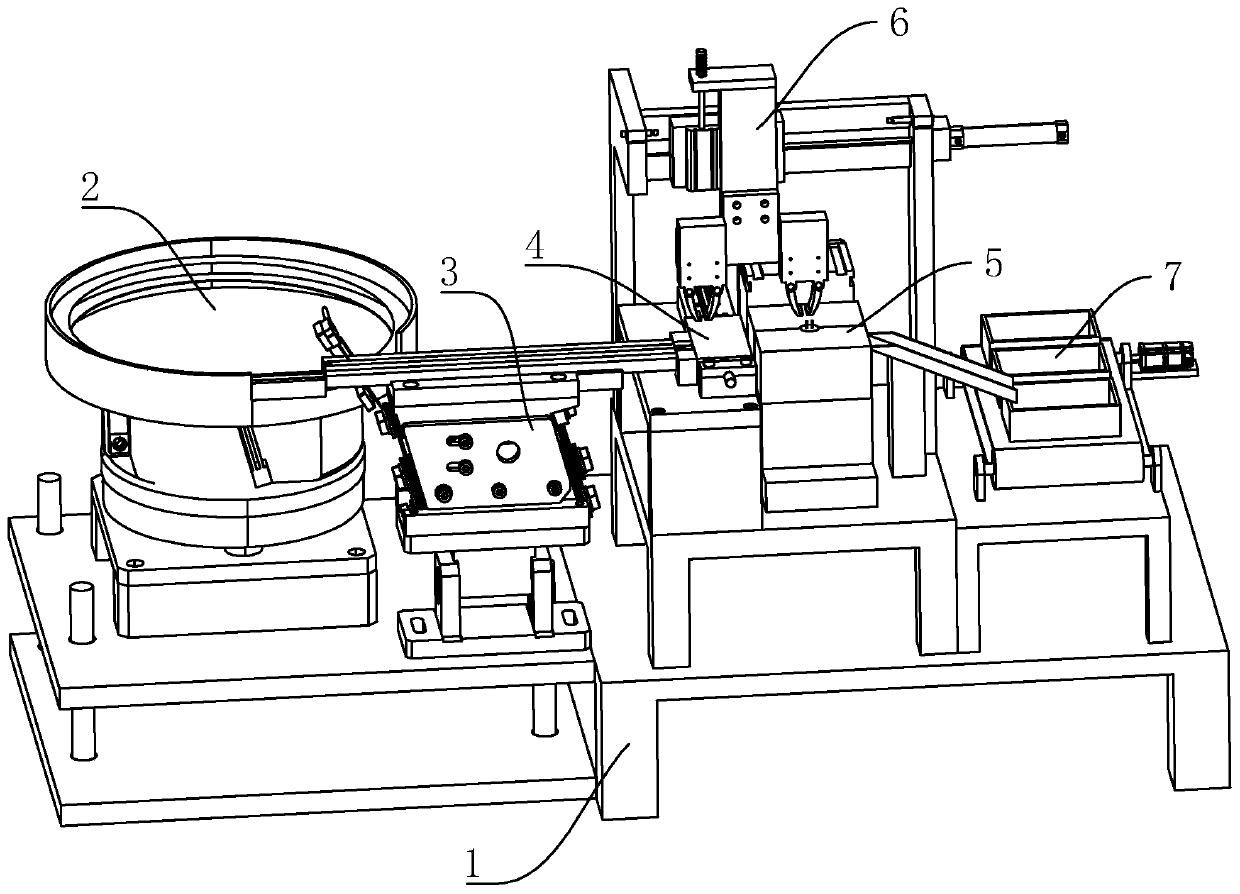

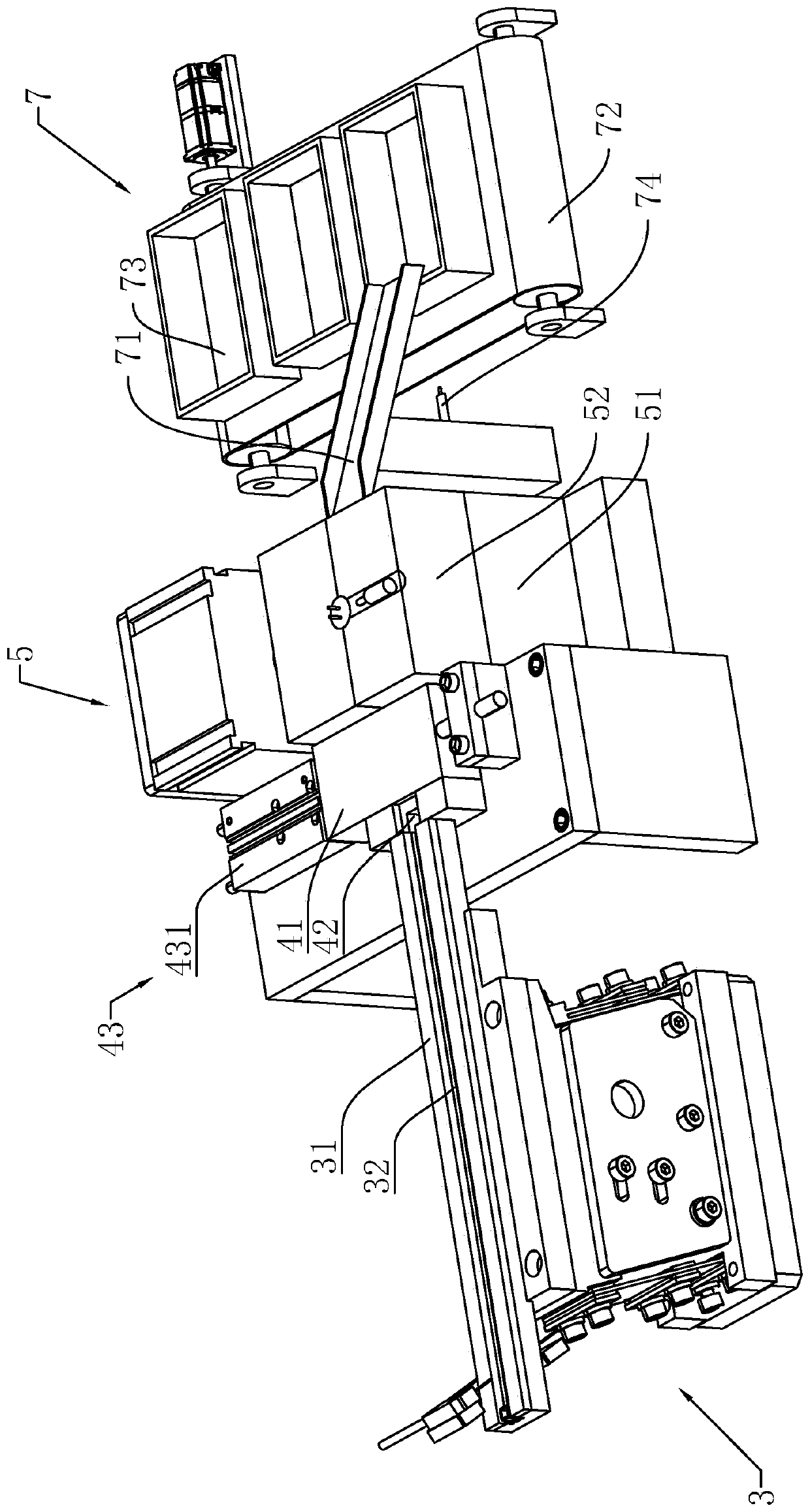

[0039] Embodiment: A kind of tube base lead wire flattening device, such as figure 2 Shown, comprise frame 1, frame 1 is provided with vibrating feed tray 2 and is provided with the feeding channel 3 on the next station of vibrating feeding tray 2, and the tail end of feeding channel 3 is provided with the branch that separates pipe base 8 individually. Material mechanism 4, the next station of material distribution mechanism 4 is provided with beating mechanism 5, is provided with receiving mechanism 7 on the next station of beating mechanism 5, is provided with between material distribution mechanism 4 and beating mechanism 5 There is a manipulator feeding mechanism 6 for sending the pipe socket 8 on the material distribution mechanism 4 to the flattening mechanism 5 and sending the pipe socket 8 on the flattening mechanism 5 to the receiving mechanism 7 .

[0040] Such as figure 2 and 3 As shown, the feeding channel 3 includes a feeding track 31, and a feeding trough 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com