A glass rough edge processing device after cutting

A technology of edge treatment and glass wool, which is applied to the parts of grinding machine tools, machine tools suitable for grinding the edge of workpieces, metal processing equipment, etc. It can solve the problem of round glass that does not meet the size requirements, reduces the efficiency of edge grinding, and has burrs on the outer wall And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

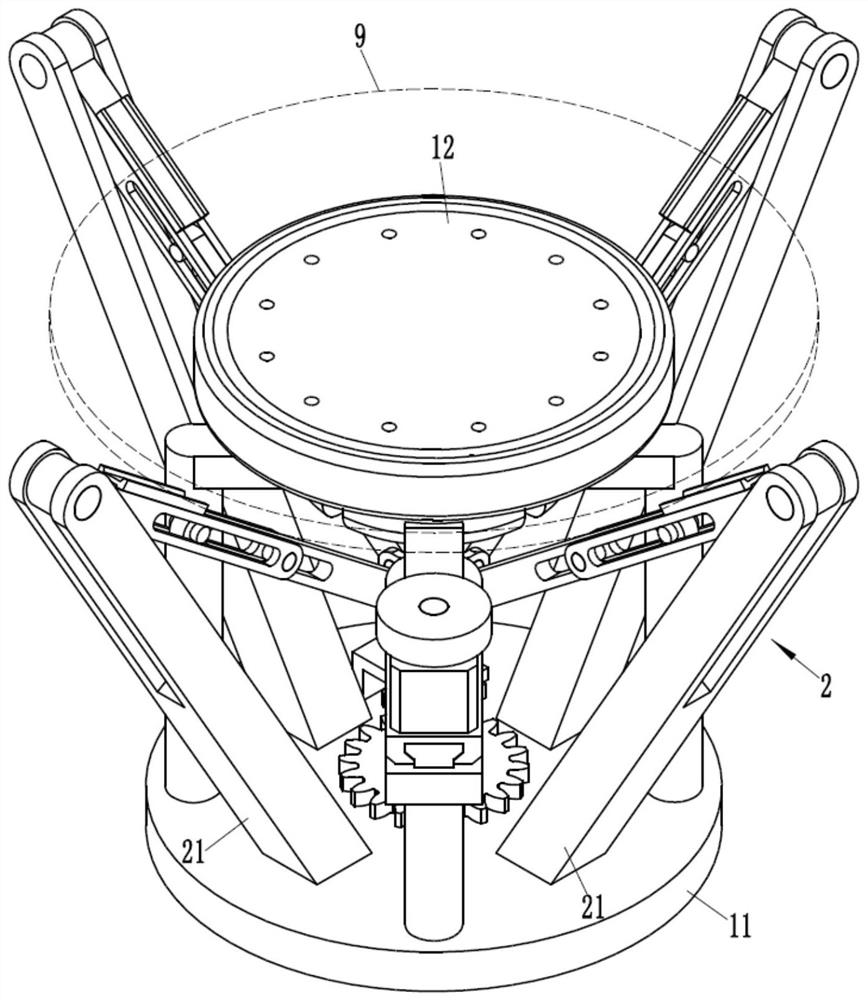

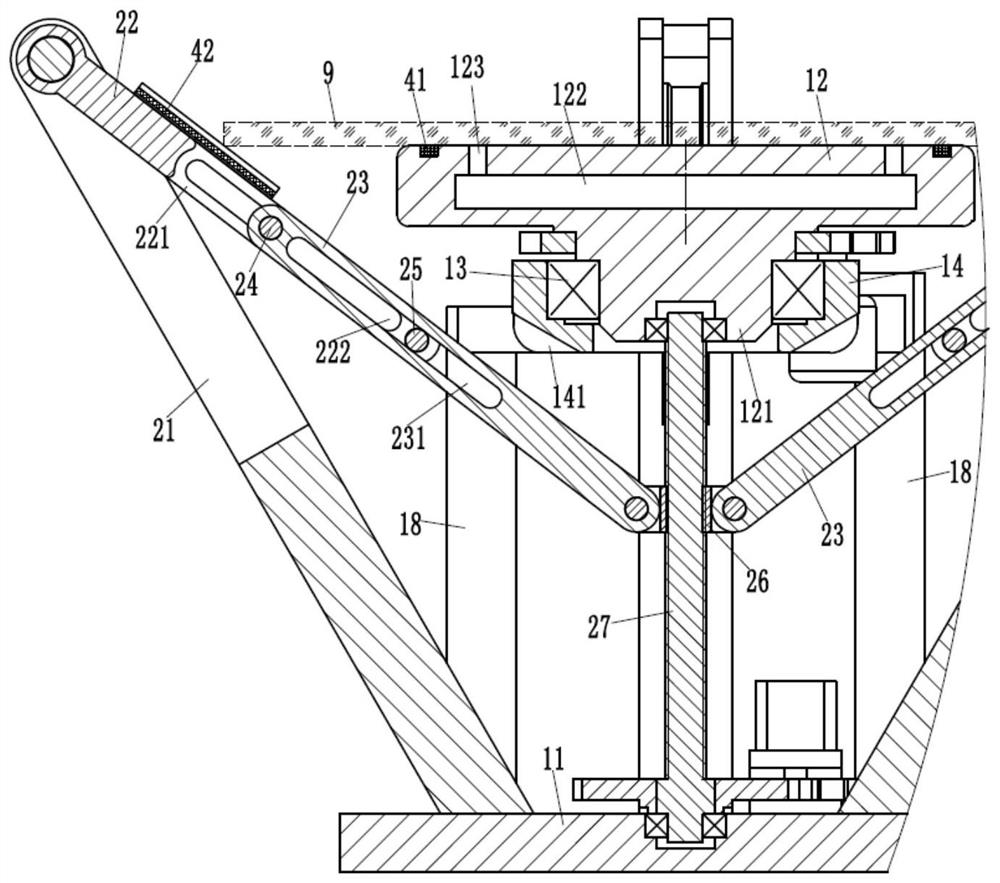

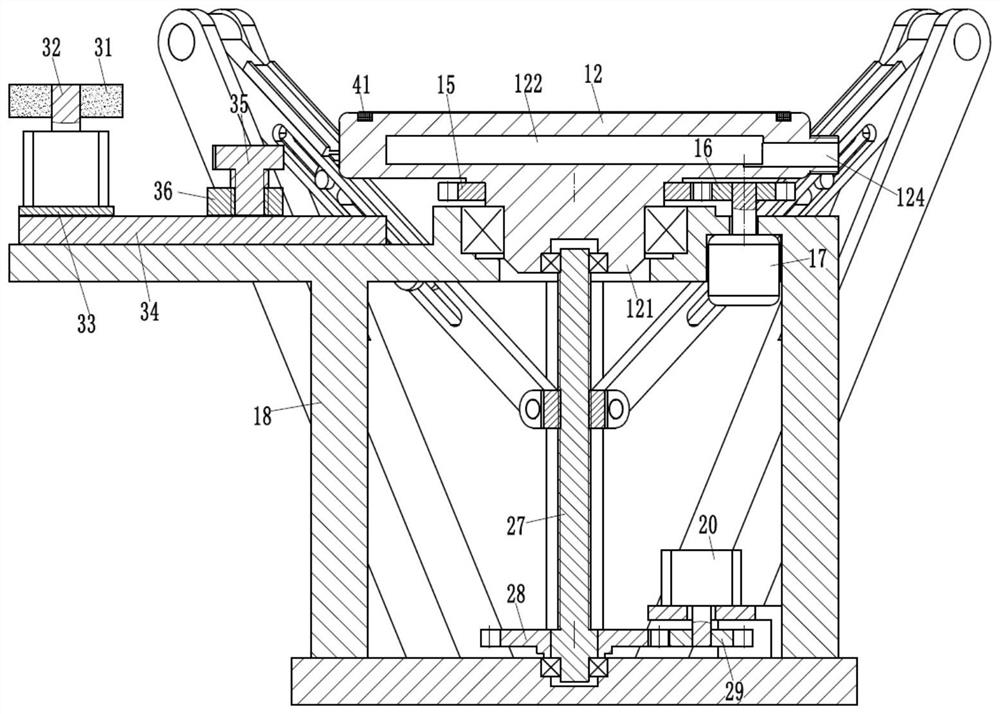

[0014] Examples, see e.g. Figure 1 to Figure 3 As shown, a glass burr processing device after cutting includes a base plate 11, a rotating platform 12 for placing glass 9 is provided directly above the base plate 11, and a stepped cylinder 121 is formed on the lower bottom surface of the rotating platform 12, and the steps The cylinder 121 is hinged on the base 14 through the bearing 13, and the base 14 is fixed on the bottom plate 11 through four uniformly distributed support arms 18. The first gear 15 is fixed on the stepped cylinder 121, and the first gear 15 meshes with the There is a second gear 16, the second gear 16 is fixed on the motor shaft of the first motor 17, and the first motor 17 is fixed on one of the support arms 18; the outside of the rotating platform 12 is provided with a glass centering device 2, so The glass centering device 2 includes four obliquely arranged uprights 21 fixed on the bottom plate 11, the four uprights 21 and the four support arms 18 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com