Refrigerator-type pneumatic material flow receiving station and pneumatic transmission system formed by refrigerator-type pneumatic material flow receiving station

A pneumatic transmission and receiving station technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of inconvenient item transfer, easy damage or deterioration, and low safety, so as to improve the efficiency and quality of item transportation and high-efficiency pneumatic logistics Effects on transmission, assurance of quality and freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

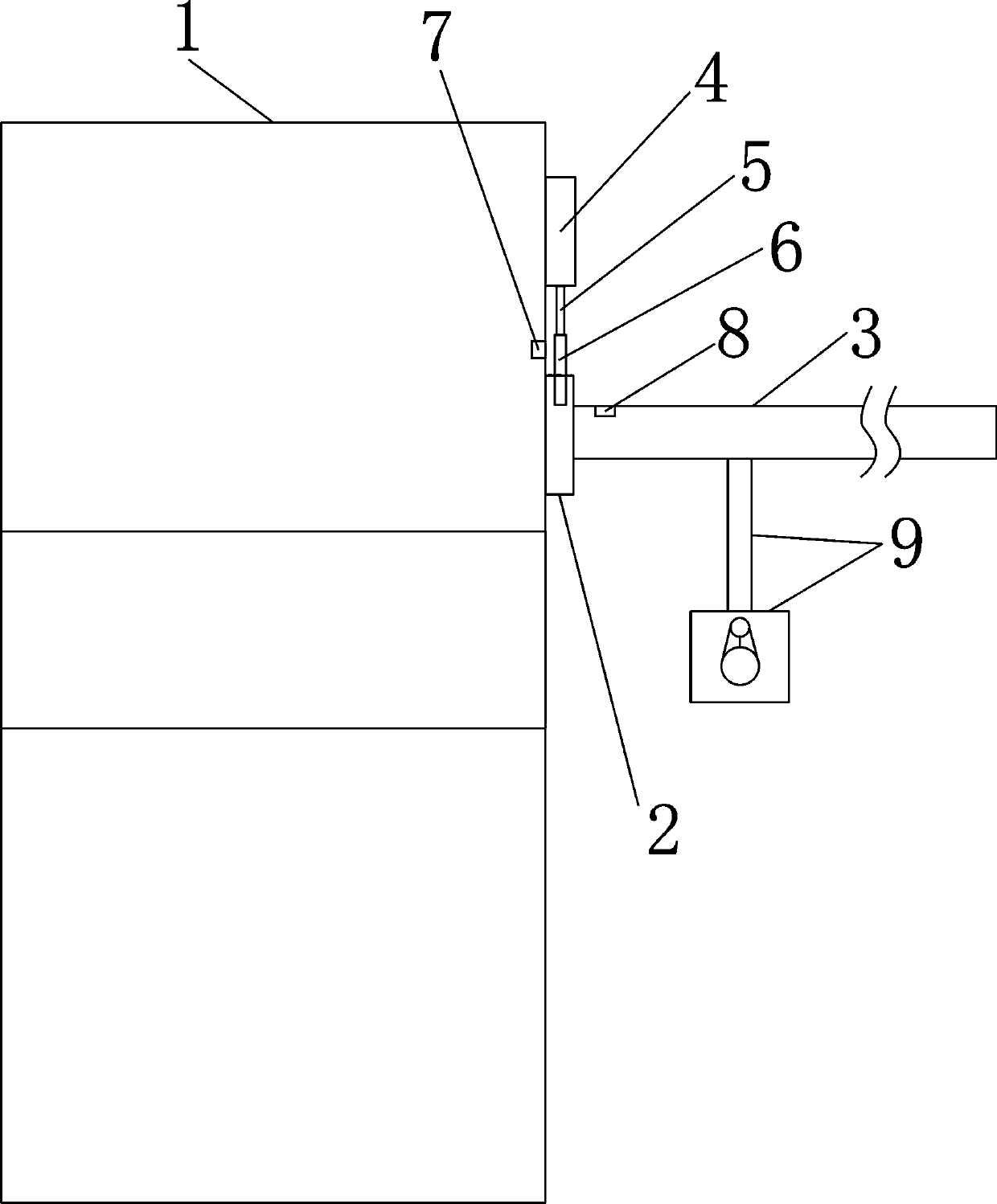

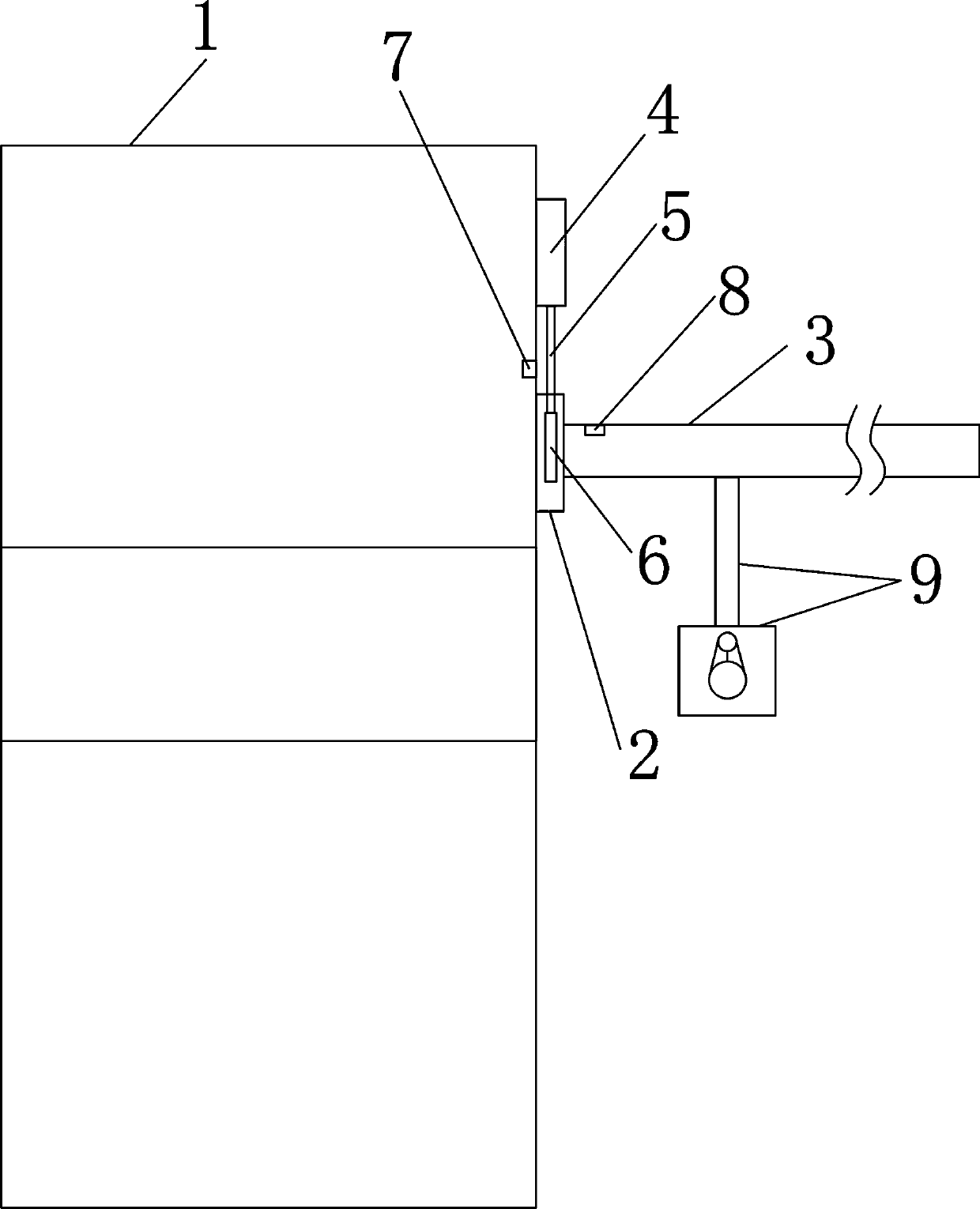

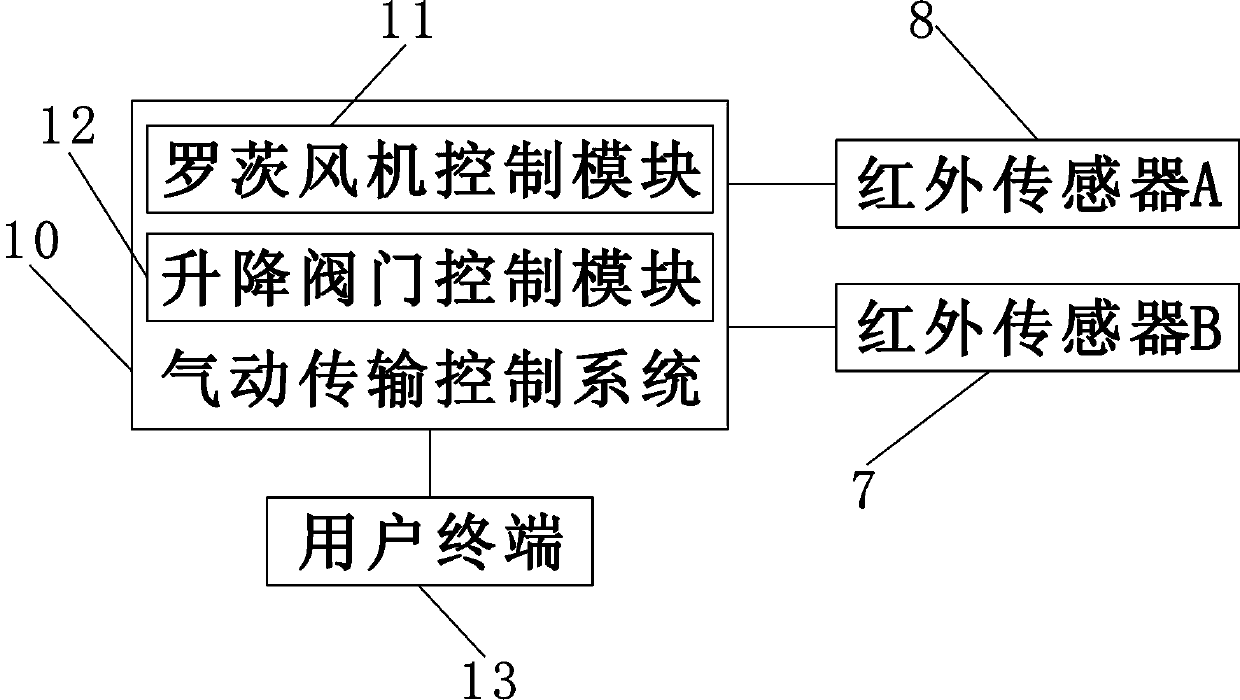

[0024] Such as Figure 1 to Figure 5 As shown, a refrigerator-type pneumatic logistics receiving station includes a refrigerator 1, a pneumatic pipeline 3, a valve housing 2 and a valve lifting assembly. An inlet is opened on the refrigerator 1, and a valve housing 2 is fixed on the outside of the refrigerator 1. The valve housing 2 It has a valve groove 21, and the valve housing 2 is provided with a pneumatic tunnel 22 that runs through the valve groove 21. The outlet end of the pneumatic pipeline 3 is airtightly connected with the pneumatic tunnel 22 of the valve casing 2. The inner cavity of the refrigerator 1, the pneumatic tunnel 22, and the pneumatic pipeline 3 are connected sequentially. The valve lifting assembly includes a driving mechanism 4 and a switch valve 6, and the preferred driving mechanism 4 of the present invention is a lifting cylinder. The drive mechanism 4 has a lifting rod 5, and the driving mechanism 4 drives the lifting rod 5 to lift and reciprocate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com