A method for preparing graphene by plasma-enhanced chemical vapor deposition

A plasma-enhanced chemical technology, applied in the field of ion-enhanced chemical vapor deposition to prepare graphene, which can solve the problems of uncontrollable number of layers and size, poor film integrity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

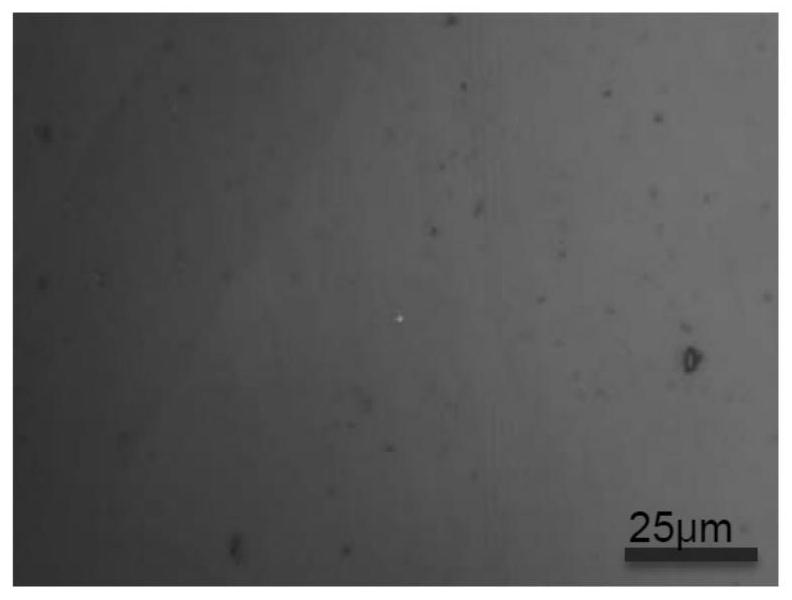

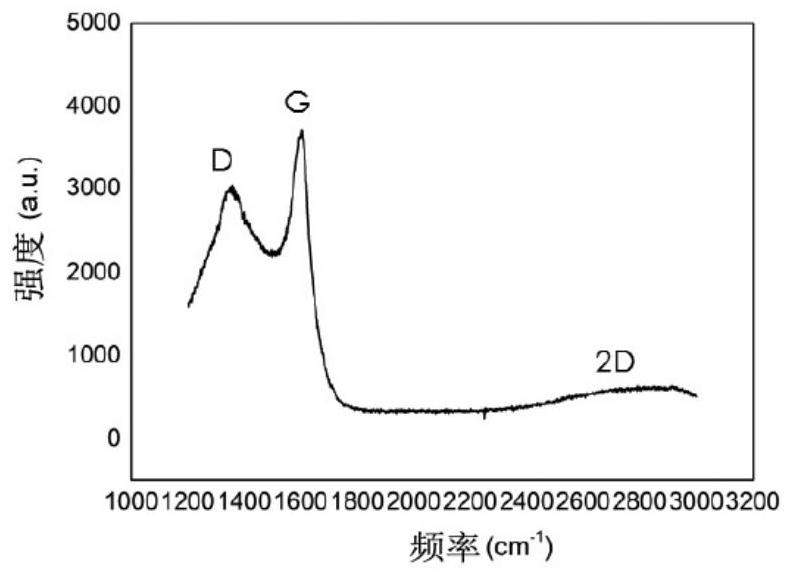

Image

Examples

Embodiment 1

[0040] A method for preparing graphene by plasma-enhanced chemical vapor deposition, comprising the following steps in turn:

[0041] 1) Prepare dilute hydrochloric acid with analytically pure concentrated hydrochloric acid and deionized water at a ratio of 1:10, put the copper foil in dilute hydrochloric acid and ultrasonically clean it for 10 minutes, remove it, and then put it into deionized water, acetone and isopropanol in turn Ultrasonic cleaning for 5 min, respectively, and drying.

[0042] 2) Cut the first piece from the copper foil, wind the first piece of copper foil into a copper tube, put the copper tube into the quartz tube, the copper tube is close to the inner wall of the quartz tube, and the copper tube and the quartz tube are aligned; Cut the second piece from the foil as the copper base, put the copper base into the copper tube, and the copper base is located at the back end of the copper tube. In this embodiment, the positional relationship of the quartz tu...

Embodiment 2~ Embodiment 5

[0047] The difference between Embodiment 2 to Embodiment 5 and Embodiment 1 lies in that the hydrogen flow rate in step 5) is different. The remaining steps of Embodiment 2 to Embodiment 5 are the same as in Embodiment 1. Table 1 is a comparison table of the hydrogen flow rates used in step 5) of Examples 1 to 5.

[0048] Table 1 Embodiment 1~Example 5 in step 3) the hydrogen flow comparison table that adopts

[0049]

Embodiment 6

[0051] The difference between embodiment 6 and embodiment 3 lies in that the radio frequency power in step 5) is different, and the radio frequency power used in step 5) in embodiment 6 is 100W. The remaining steps of embodiment 6 are all the same as embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com