A photosensitive zr-b-si-c ceramic precursor and its in-situ preparation method

A ceramic precursor, zr-b-si-c technology, applied in the field of ceramic materials, can solve problems such as high viscosity, complicated process, and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

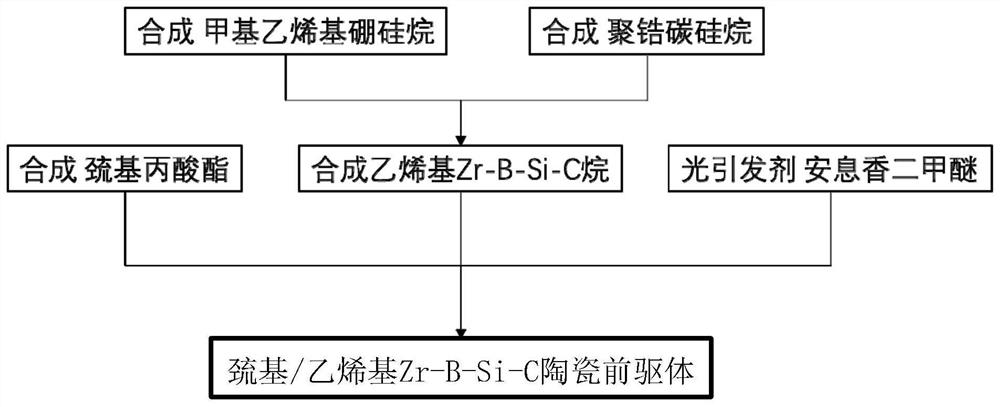

[0026] The present invention provides a kind of preparation method of photosensitive Zr-B-Si-C ceramic precursor in the first aspect, described method comprises the following steps:

[0027] (1) Methyl vinyl dichlorosilane (C 3 h 6 Cl 2 Si) and borane dimethyl sulfide ((CH 3 ) 2 S·BH 3 ) to mix uniformly to obtain the first mixed solution, and then add metal sodium (Na) to the first mixed solution for dechlorination to obtain methylvinyl borosilane; in the present invention, the toluene solution is, for example, toluene standard solution;

[0028] (2) Chloromethyltrichlorosilane (CH 2 Cl 4 Si), Methylchloromethyldichlorosilane (C 2 h 5 Cl 3 Si) and dichlorozirconocene (C 10 h 10 Cl 2 Zr) mix uniformly to obtain a second mixed solution, then add metal magnesium (Mg) to the second mixed solution to carry out the first heat preservation reaction to obtain a reaction solution, then add a reducing agent to the reaction solution to carry out the second heat preservation...

Embodiment 1

[0056] This embodiment provides a preparation method for in-situ synthesis of a photosensitive Zr-B-Si-C ceramic precursor, the preparation method comprising the following steps:

[0057] S1. Melt 13.4g of trimethylolpropane into 100mL of toluene solvent, add 1g of concentrated sulfuric acid as an acidic catalyst; after heating to boiling, add 31.8g of 3-mercaptopropionic acid, fully react, wash with water until neutral, and then distill under reduced pressure to obtain Mercaptopropionate.

[0058] S2, in N 2 Under the protection of an inert gas, dissolve 21.2g of methylvinyldichlorosilane into 100mL of toluene solution, then add 3.8g of borane dimethyl sulfide to obtain the first mixed solution, and then add 6.9 g of metal Na was dechlorinated, and liquid methylvinyl borosilane was obtained after standing at room temperature, extraction, and filtration.

[0059] S3, in N 2 Under inert gas protection, 18.4g (chloromethyl) trichlorosilane (CH 2 Cl 4 Si), 16.4g (chloromethy...

Embodiment 2

[0064] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0065] In step S5, the amount of benzoin dimethyl ether photoinitiator is 1 mL, that is, the amount of benzoin dimethyl ether is 0.25 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com