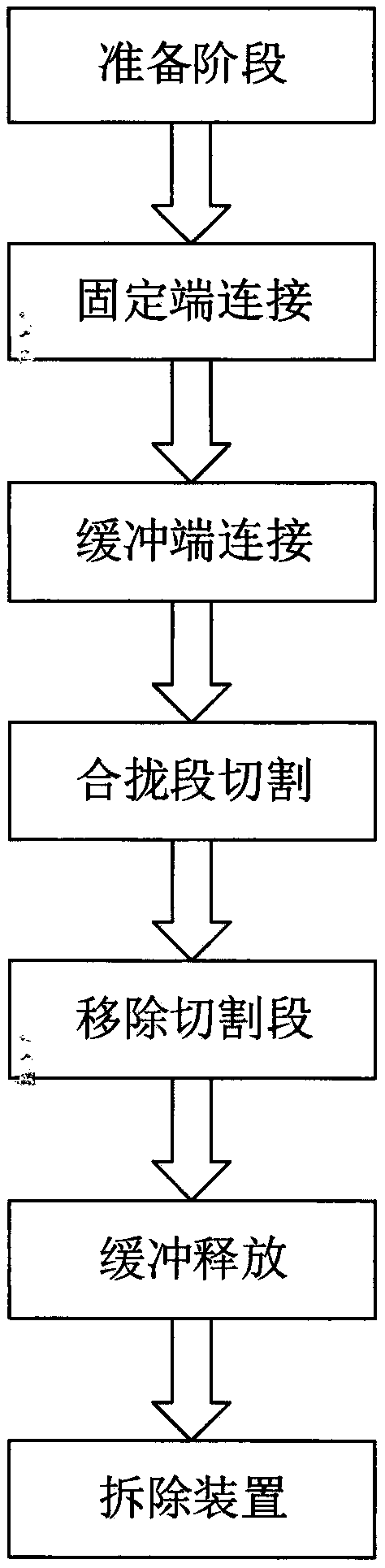

Deformation control method for dismantling continuous box girder bridge midspan closure segment

A deformation control and closing section technology, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve problems such as the inability to fully reflect the flip-chip dismantling method, reduce the final vertical deformation of the cutting span, and reduce the bearing capacity of old and dangerous bridges. Achieving the effect of good bridge demolition, fast construction speed and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

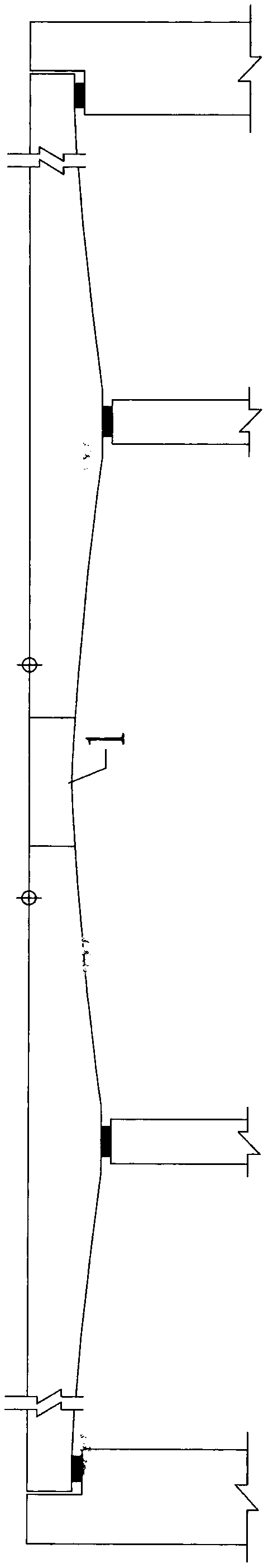

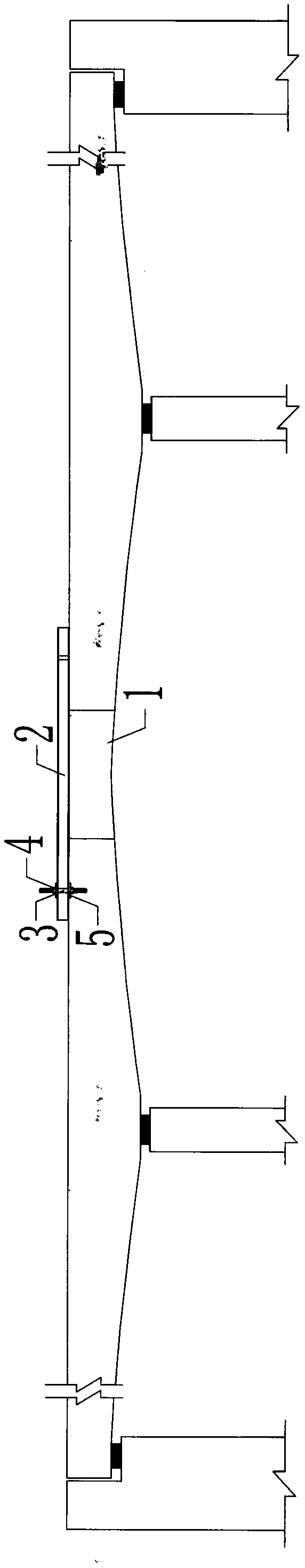

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0036] As shown in the accompanying drawings, the present invention provides a deformation control method for dismantling the mid-span closing section of a continuous box girder bridge, which is characterized in that the deformation of the closing section 1 is controlled by a restraint device, the top plate of the closing section 1 is perforated, and the rigid steel The bone 2 is placed on the upper surface of the top plate of the closing section 1 along the bridge direction, the fixed end of the stiff steel bone 2 is tightly bolted to the closing section 1 through the interspersed suspender 3 and nut washer 5, and the buffer end of the stiff steel bone 2 A hollow jack 6 is arranged on the upper part, and the two ends of the suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com