Constant-resistance contractible flexible support device and roof cutting gob-side entry retaining blocking gangue support system

A supporting device, flexible technology, applied in the direction of pillars/brackets, installation bolts, mining equipment, etc., can solve the problems of loss of gangue retaining ability, bending deformation, large amount of roof and floor moving closer, etc., to avoid vertical The effect of compression bending failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

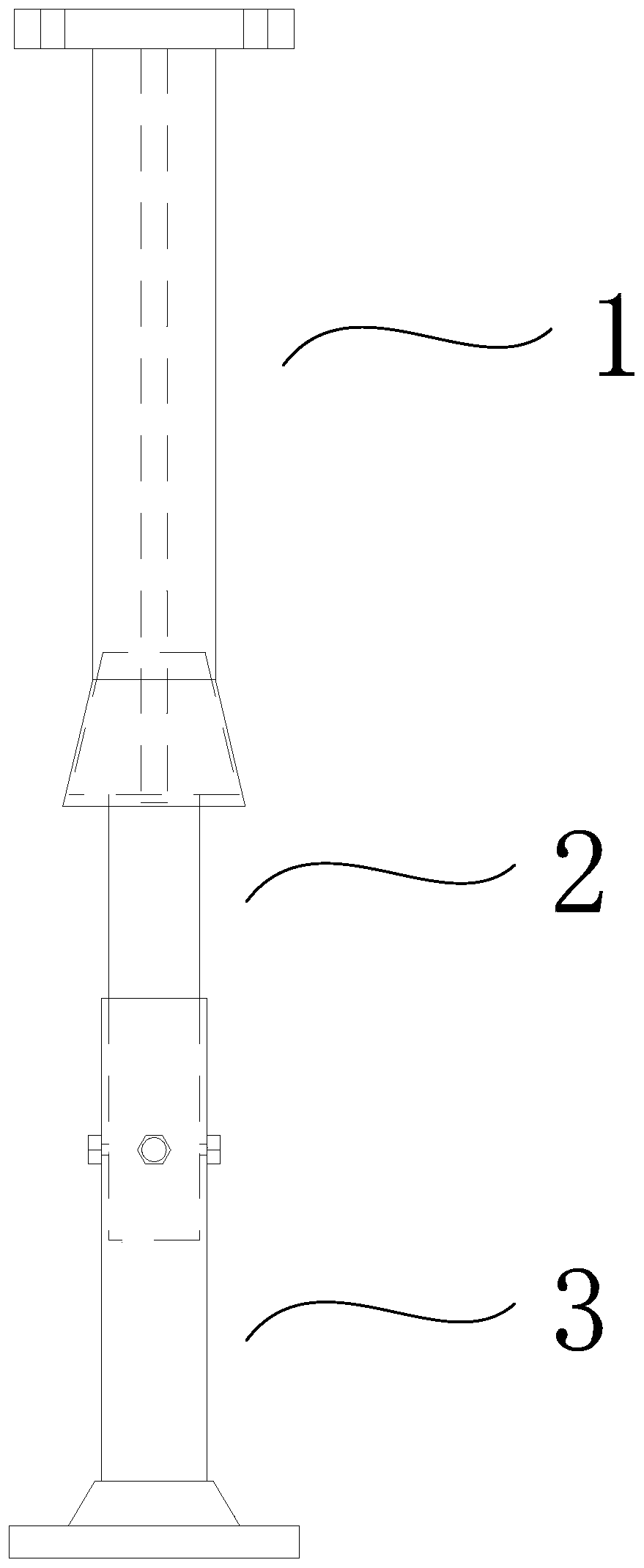

[0047] Such as figure 1 As shown, the embodiment of the present application provides a constant resistance shrinkable flexible support device, which includes a cylinder body 1 , a rod body 2 and a support portion 3 .

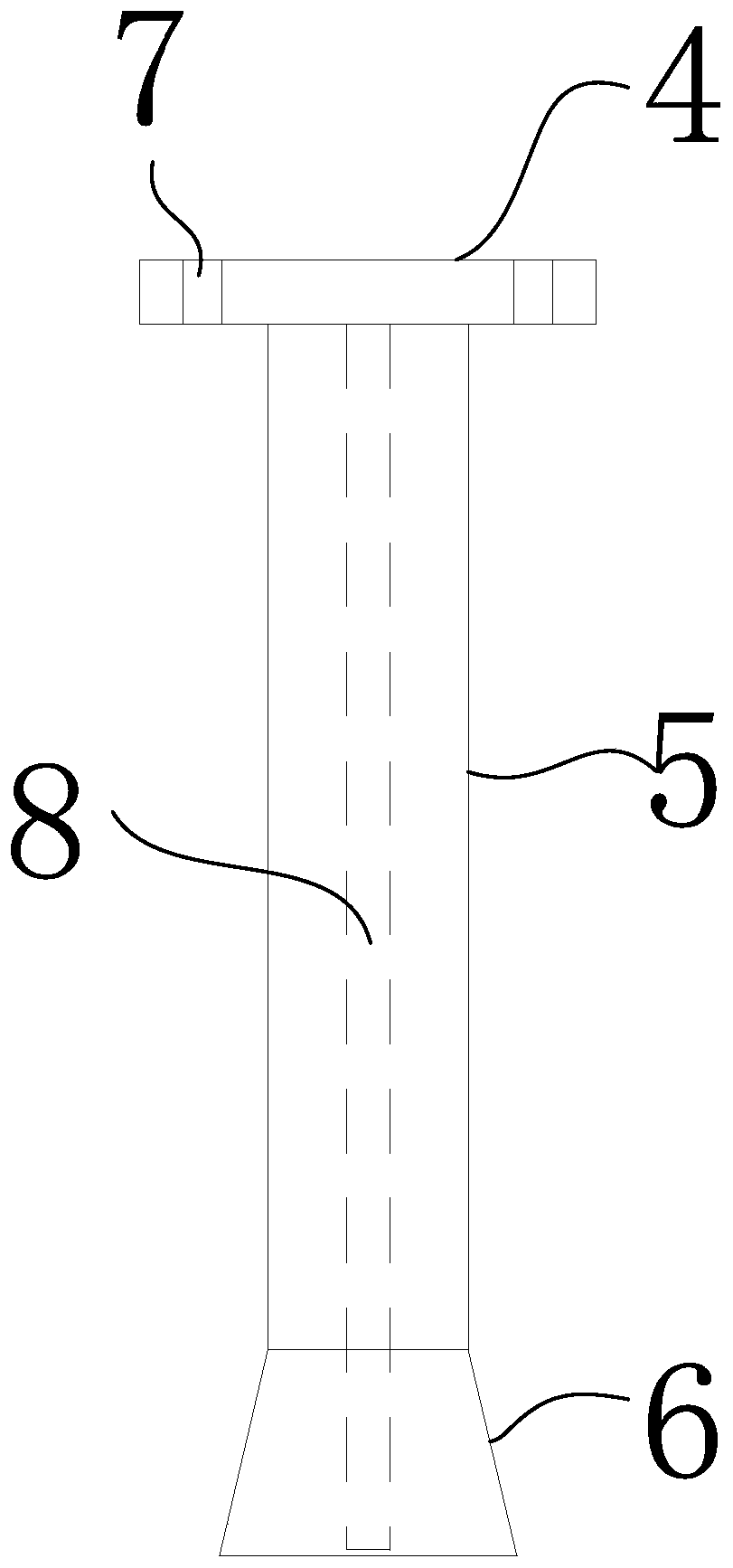

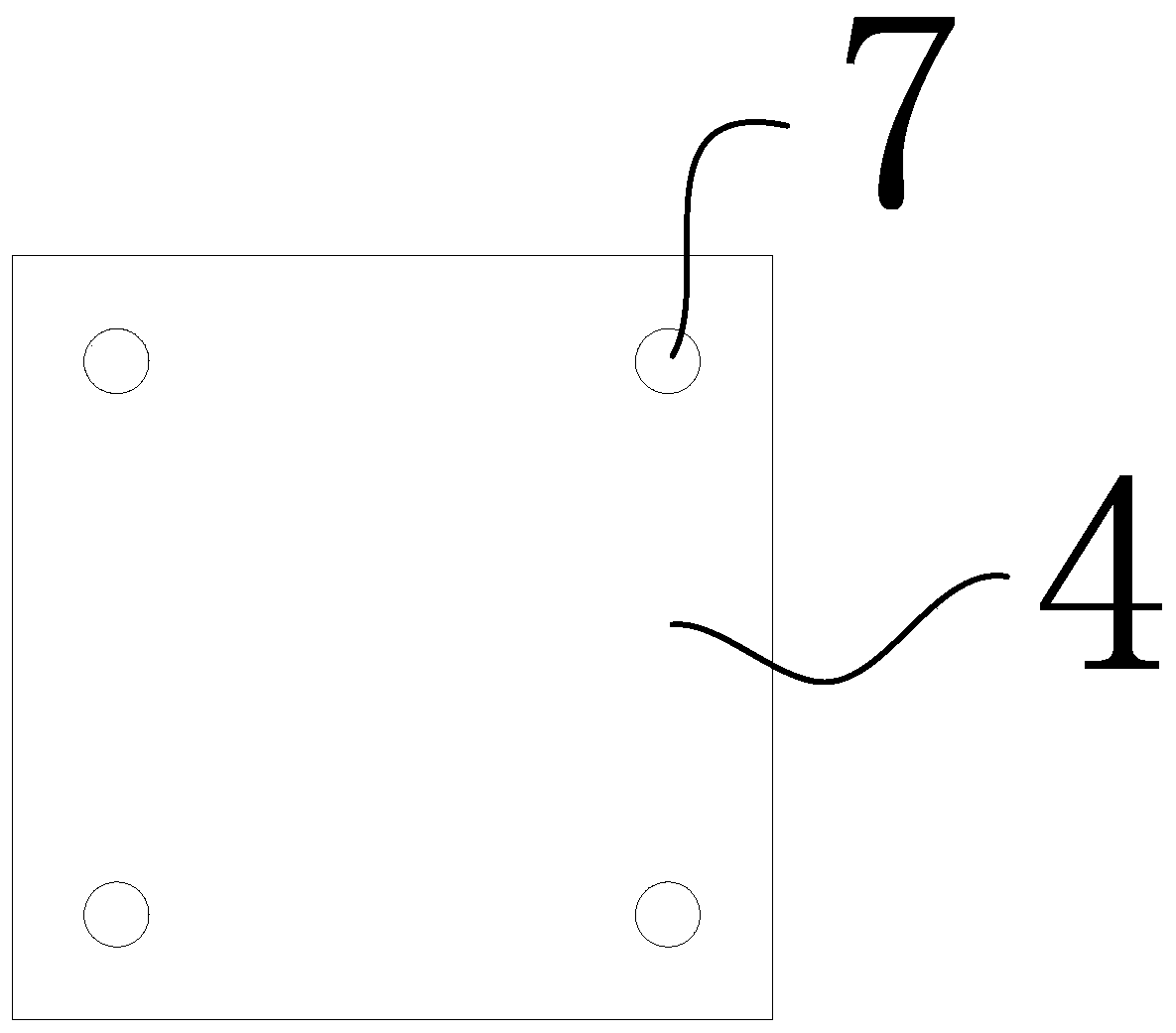

[0048] Such as Figure 2-5 As shown, the cylinder body 1 includes a tray 4, a straight part 5 and a tapered barrel 6 connected in sequence. A guide rod 8 is formed inside the straight part 5. One end of the guide rod 8 is fixed on the tray 4, and the other end extends to the tapered barrel 6. Inside, the inner diameter and outer diameter of the tapered cylinder 6 gradually expand from one end connected to the straight cylinder portion 5 to the other end. The tray 4 is used to be attached to the top plate that needs to be supported. As shown in the figure, the tray 4 is vertically arranged with the straight barrel portion 5. After the tray 4 is attached to the top plate, the verticality of the straight barrel portion 5 can be guaranteed.

[0049] Such as Figu...

Embodiment 2

[0057] Such as Figure 13 As shown, the embodiment of the present application also provides a gangue retaining support system for gob-cut entry, which includes a gangue-retaining pillar 18, a roof net (not shown in the figure), a gangue-retaining net 17 and an anchor rod 16, The gangue retaining pillars 18 are constant resistance and shrinkable flexible support devices provided in Embodiment 1 of the present application. The gangue retaining pillars 18 are arranged at intervals along the top cutting line in the roadway. The gangue net 17 is connected with the top net and is fixed on the gangue retaining pillar 18, and the pallet 4 is fixed in the roof stratum by the anchor rod 16.

[0058] In some embodiments, the gangue-retaining net 17 is preferably a metal mesh, and the gangue-retaining net 17 is bound to the gangue-retaining pillar 18 by a wire, and the gangue-retaining net 17 and the top net may also be bound by a wire.

[0059] In the process of roof cutting and gob-sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com