Plastic pipe capable of being protected against high-temperature deformation

A plastic pipe, high-temperature deformation technology, used in thermal insulation, pipes, rigid pipes, etc., can solve problems such as easy deformation, and achieve the effect of prolonging service life, improving quality, and preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 provides a high-temperature deformation-resistant plastic pipe, including an inner pipe and an outer layer, the outer layer and the inner pipe are connected through a skeleton, and a gap is formed between the outer layer and the inner pipe.

[0028] The plastic pipe in Example 1 is connected to the inner pipe through the skeleton, and when the inner pipe receives the action of gravity, the skeleton structure can provide better support for the inner pipe; Therefore, it can always maintain a high hardness for support, preventing the inner tube from deforming due to gravity when it is heated and softened; at the same time, because the inner tube is completely covered by the outer layer, the inner tube will not accelerate aging when it is exposed to the sun outdoors. Thus, the service life can be extended.

Embodiment 2

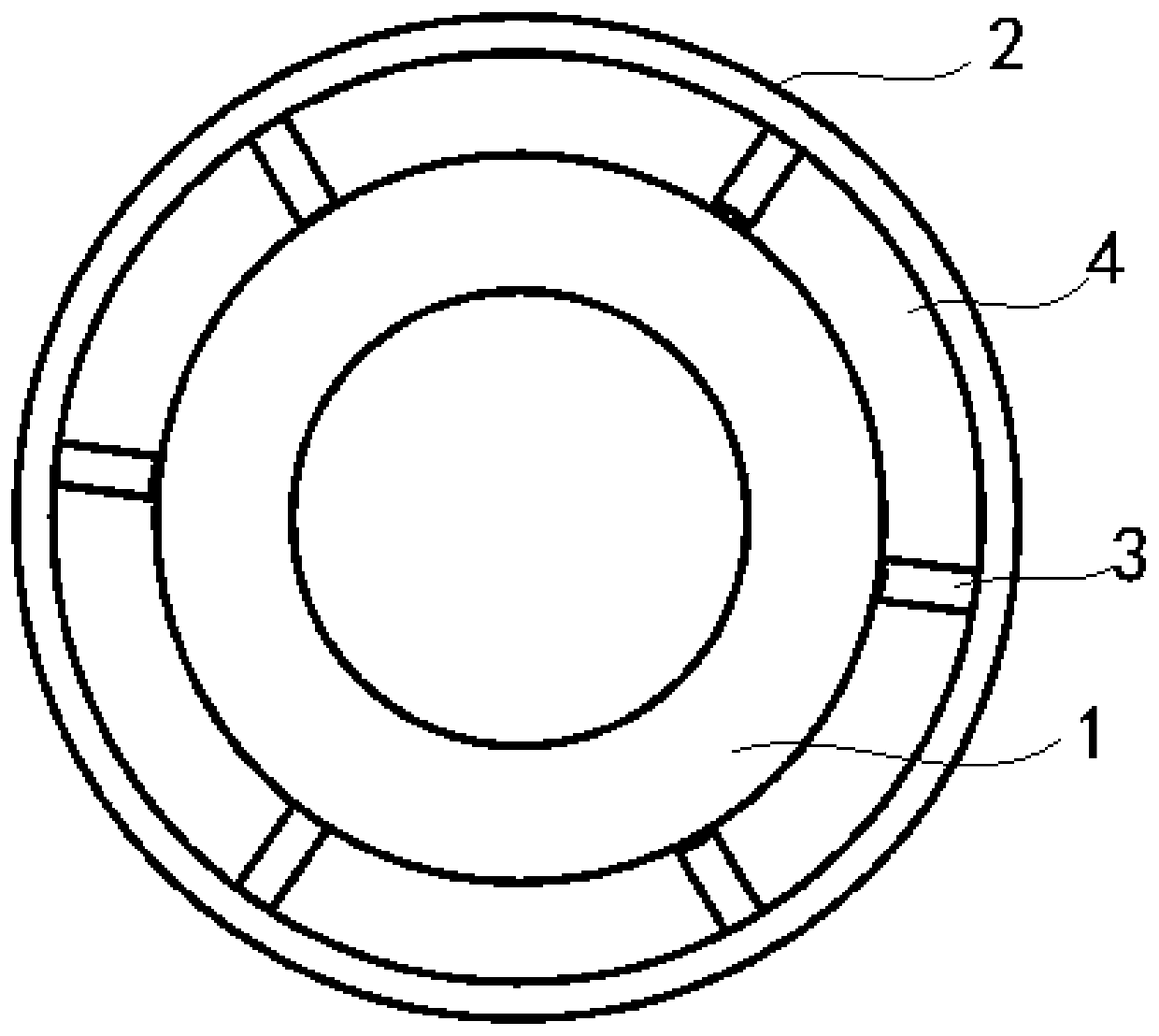

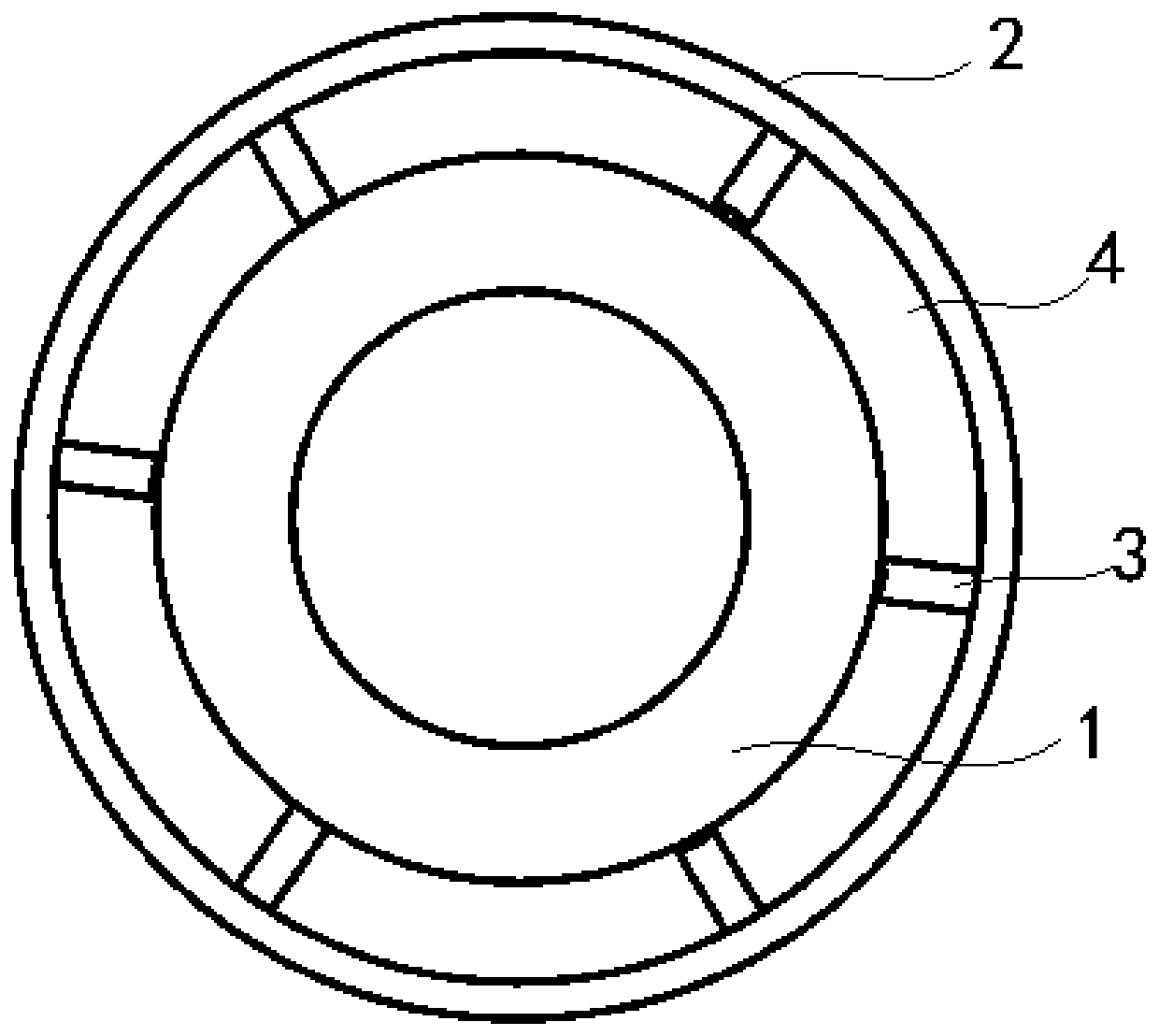

[0030] Such as figure 2 As shown, this embodiment 2 provides a plastic pipe that prevents high-temperature deformation, including a PPR inner pipe 1 and an outer layer 2, the outer layer 2 is connected to the PPR inner pipe 1 through a skeleton, and the outer layer 2 and the outer layer 2 are connected to each other through a skeleton. A gap is formed between the PPR inner tubes 1, and the skeleton is composed of six brackets 3 radially spaced along the PPR inner tube 1, one end of the brackets 3 is connected to the outer wall of the PPR inner tube 1, and the brackets 3 The other end is connected to the inner wall of the outer layer 2, and six brackets 3 are arranged at equal intervals to form a stable structure. In Embodiment 2, the six brackets 3 are symmetrically arranged in pairs. The number of brackets 3 used in this embodiment 2 is only an optimal solution. In actual use, as long as there are two brackets 3 connecting the PPR inner tube 1 and the outer layer 2, the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com