Water diversion vertical shaft defect detection method based on three-dimensional laser scanning technology

A technology of three-dimensional laser and scanning technology, which is applied in the field of water diversion shaft defect detection, and can solve problems such as difficult detection of water diversion shaft defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0059] The present invention uses the three-dimensional laser scanning data of the water diversion shaft obtained by the 100-meter-level water diversion shaft health detection equipment and method recorded in the patent CN107561085A "A Large-Scale Hydropower Station 100-meter-level Diversion Shaft Health Detection Equipment and Method", and proposes a water diversion shaft defect detection The method is helpful to timely check out the potential safety hazards in the shaft section of the diversion channel, and provides a strong guarantee for the safe operation of the hydropower station.

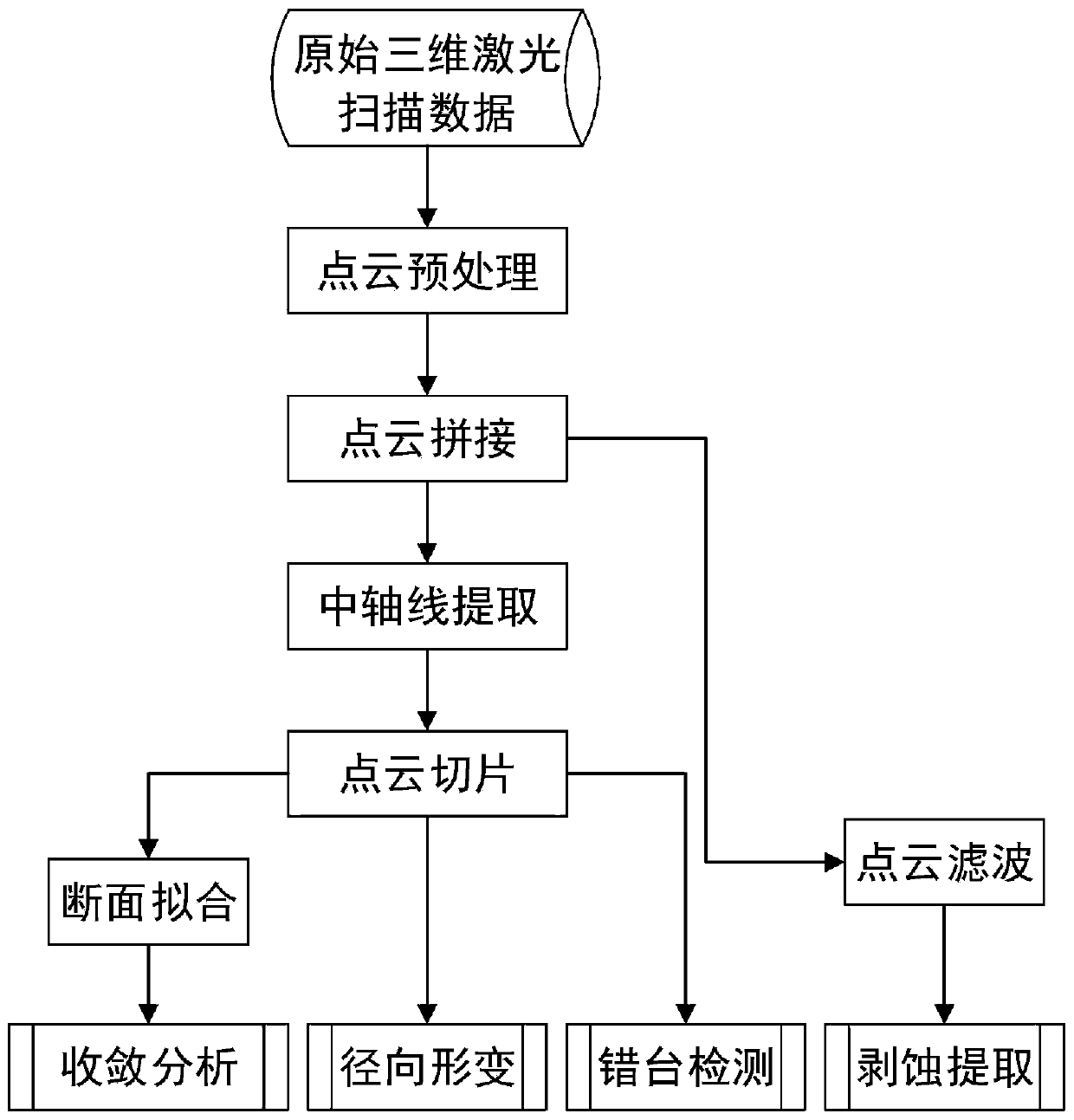

[0060] This method first denoises the point cloud data, and uses a straight-through filter to remove abnormal points caused by mooring ropes and equipment occlusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com