Glass defect detection method based on transmission-type structured light illumination

A technology of structured light illumination and defect detection, which is used in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of inability to obtain high-contrast defect images, inability to achieve area array detection, and weak scattered light intensity. Avoid lighting verification tests, improve defect detection efficiency, and enhance the effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

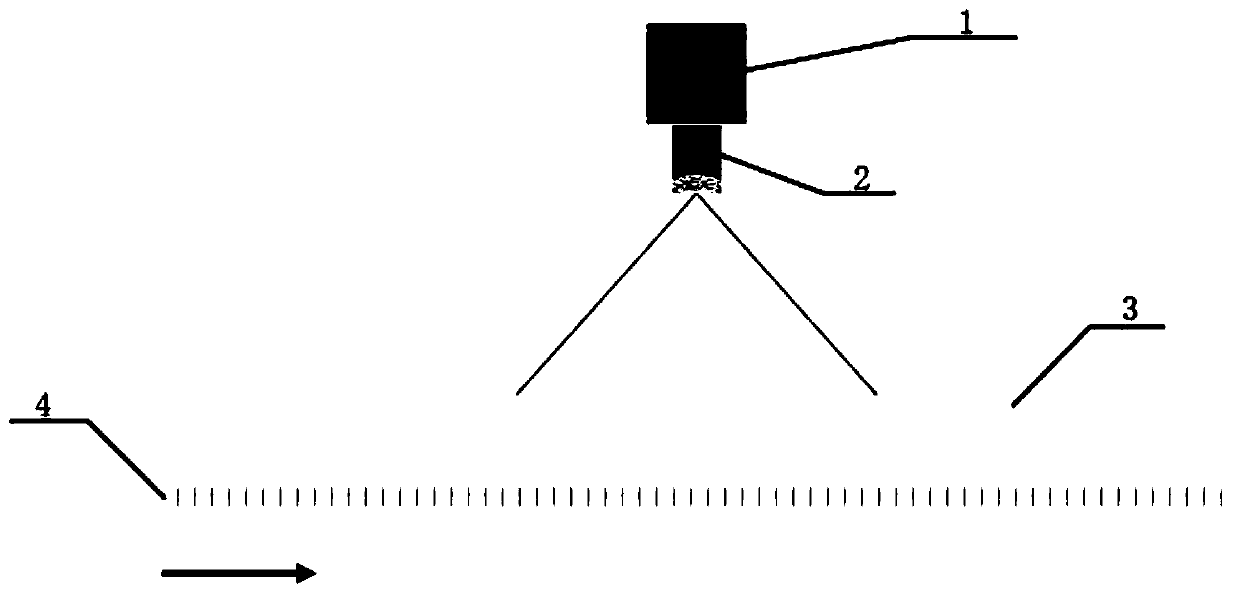

[0025] Such as figure 1 , Figure 3 ~ Figure 7 Shown, the present invention comprises the steps:

[0026] S1. The area array camera 1 and the optical lens 2 on it are set above the glass sample 3 to be inspected, and the distance between the area array camera 1 and the glass sample 3 to be inspected is adjusted so that the area array camera 1 and the glass sample 3 to be inspected are clear imaging;

[0027] S2, the structured light source is generated by the liquid crystal display 4, and the light intensity on the structured light source is distributed in sinusoidal stripes, that is, the liquid crystal display 4 displays sinusoidal structural stripes as a structured light source; the liquid crystal display 4 is placed directly below the glass sample 3 to be tested for a certain period of time. At the defocus distance, the distance between the liquid crystal display 4 and the glass sample 3 to be inspected satisfies that the spatial resolution of the imaging system composed ...

Embodiment 2

[0032] Such as figure 2 As shown, the structured light source is projected onto the frosted glass 5 by the projector 6 to make the ground glass 5 a structured light source. The ground glass 5 is placed at a certain defocus distance below the glass sample 3 to be inspected. The distance between the frosted glass 5 and the glass sample 3 to be inspected is The distance between them satisfies that the spatial resolution of the imaging system composed of the area array camera 1 and the optical lens 2 on it and the structured light source is lower than 1 / 2 of the period of the structured light source; the projector 6 is located below the frosted glass 5; The size of the microstructure on the surface of the ground glass 5 is not larger than the resolution of the area array camera 1 on the surface of the ground glass. Specifically, the detection method for enhancing various internal and external defects of the glass is the same as above.

[0033] The detection method of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com