Distributed optical fiber monitoring method for surface expansion deformation of flexible buffer airbag

A flexible cushioning and airbag technology, which is applied in the direction of measuring devices, optical devices, and special data processing applications, can solve problems such as real-time monitoring and calculation of the deformation state of flexible inflatable structures, difficulty in accurately capturing, and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] specific implementation plan

[0060] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings: Aiming at the expansion and deformation of the flexible buffer airbag, a flexible airbag structure is proposed under the action of different internal pressures, and the distributed fiber grating sensor network is used to realize the expansion and deformation of the surface of the airbag. Calculation method.

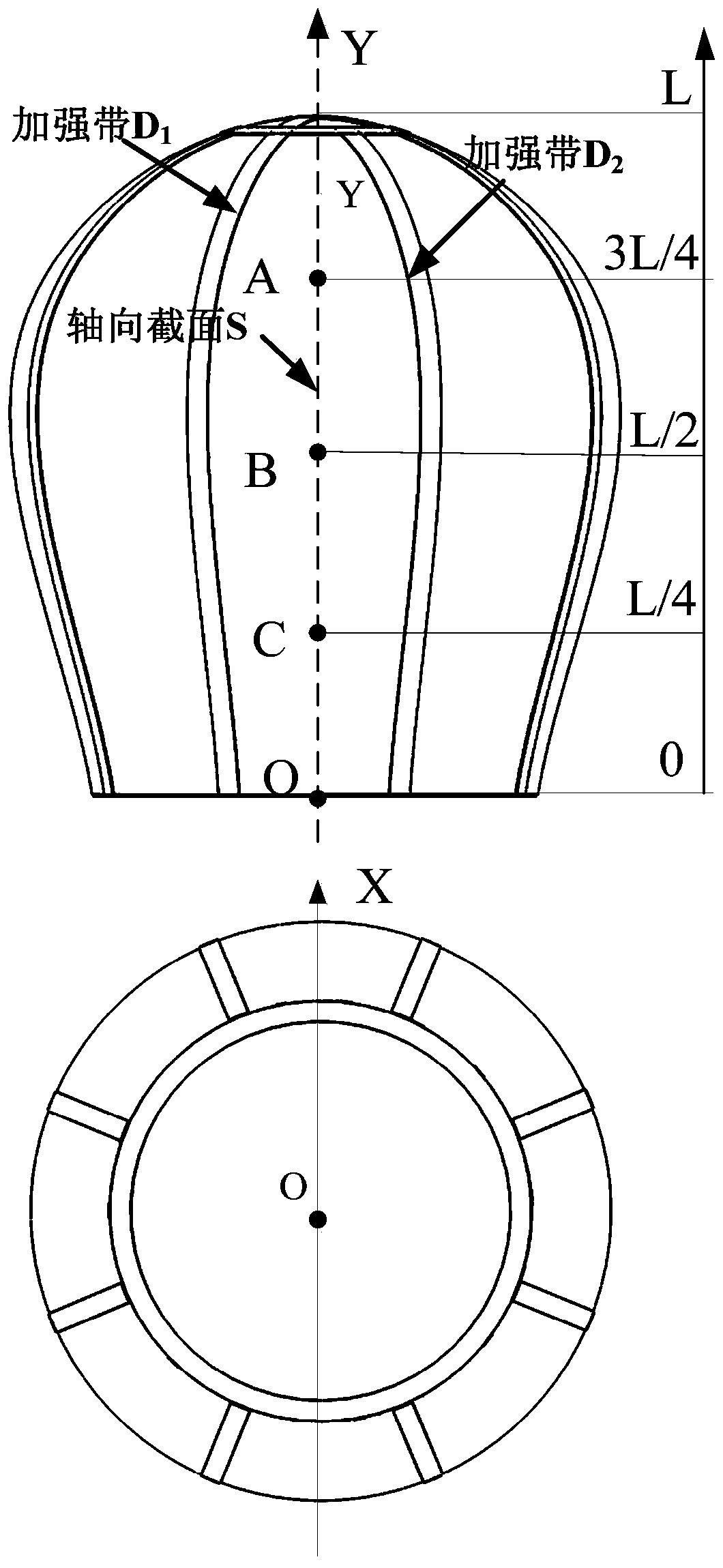

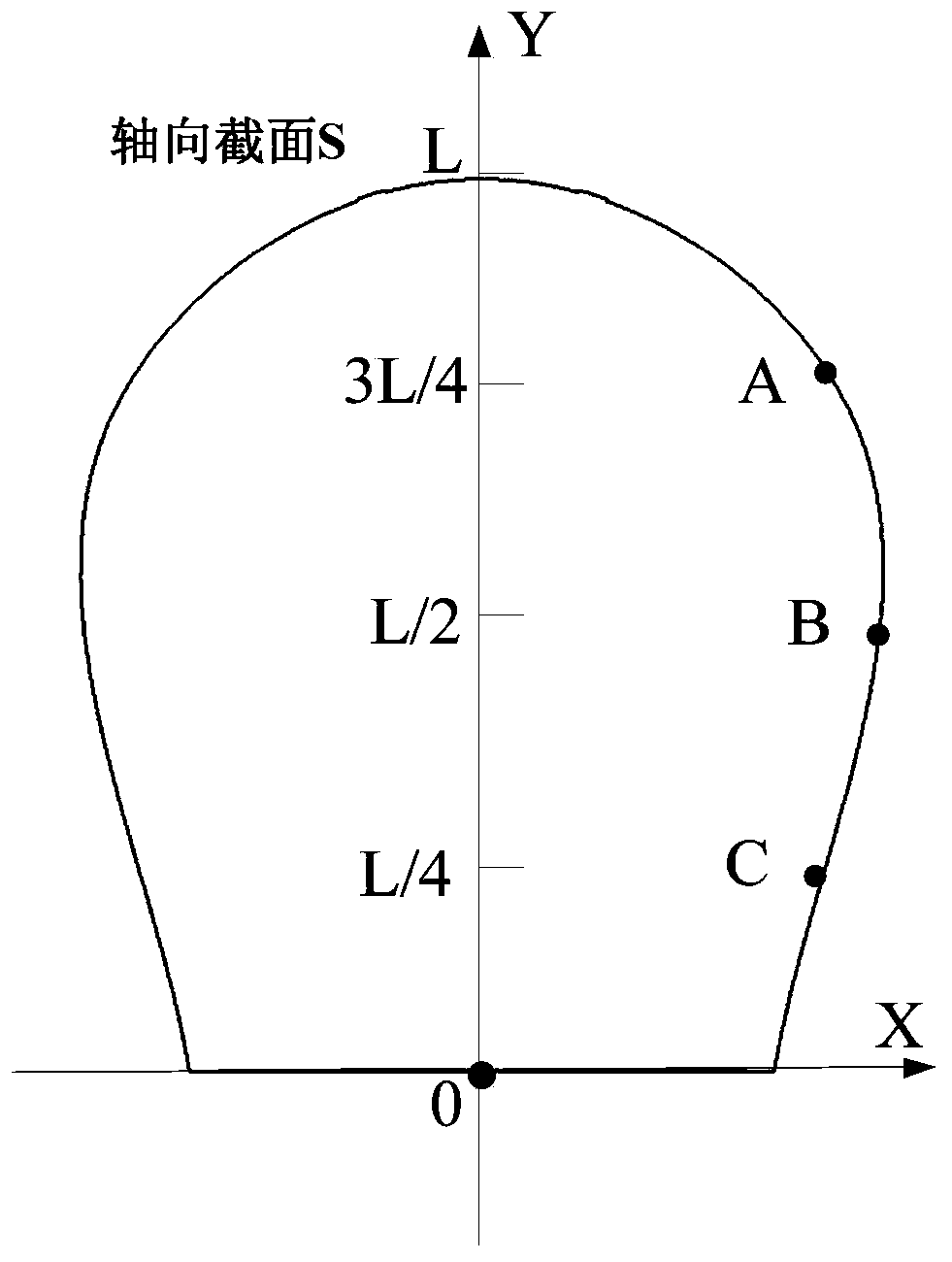

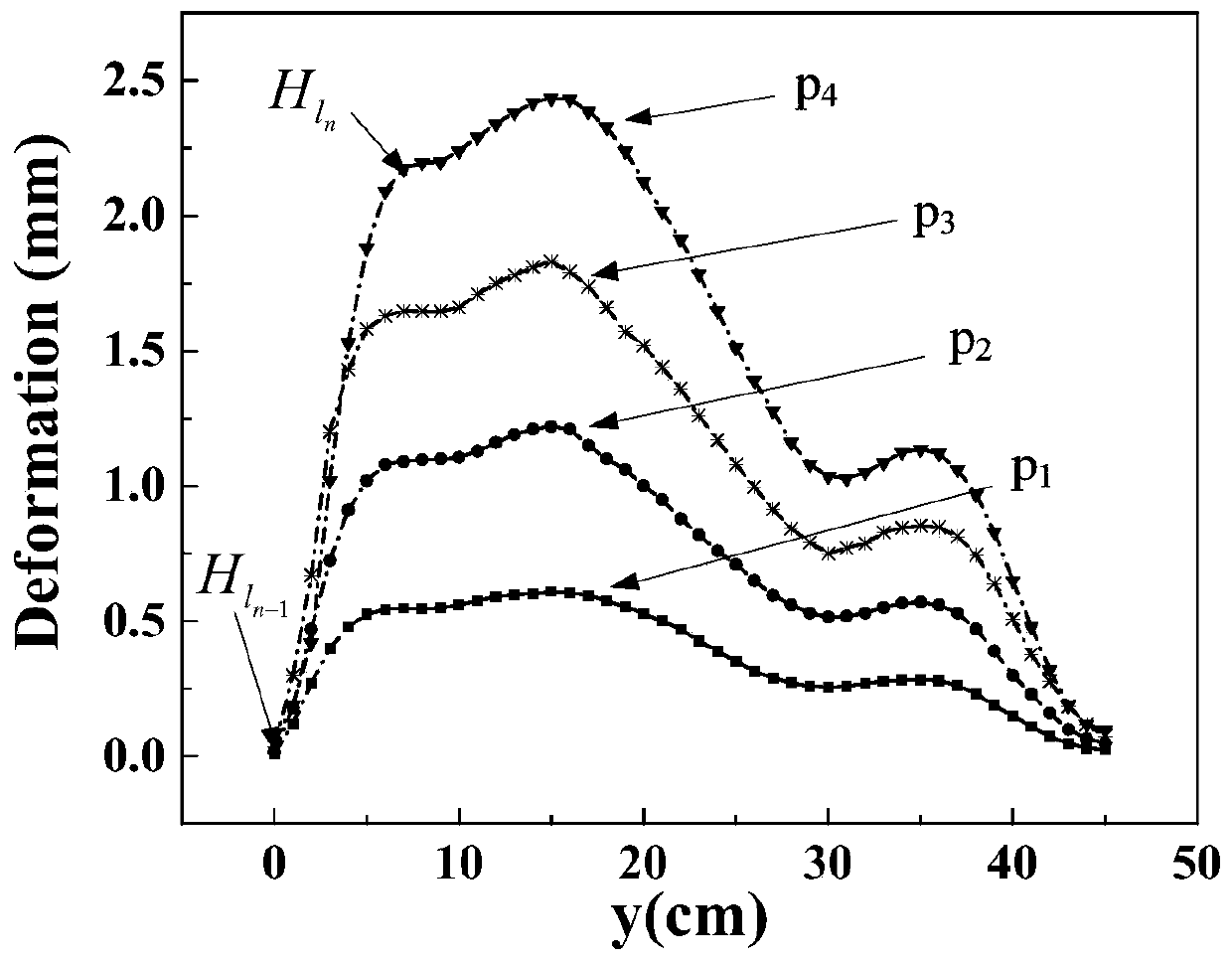

[0061] Step 1: The finite element simulation method is used to numerically simulate the expansion and deformation characteristics of the surface of the flexible buffer airbag structure under different internal pressures, and the deformation characteristics and strain distribution characteristics of the bladder under different internal pressures are obtained. Select the surface reinforcement belt D of the flexible buffer airbag 1 and reinforcement band D 2 The axial section with the largest relative deformat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com